Epoxy resin/montmorillonite nanometer composite paint used on metal surface and application of epoxy resin/montmorillonite nanometer composite coating

An epoxy resin and metal surface technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of inability to achieve anti-corrosion on metal surfaces, dirty anti-corrosion film layers on metal surfaces, slow curing and drying speed, etc. Curing drying speed, reducing the probability of self-corrosion phenomenon, the effect of accelerating drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

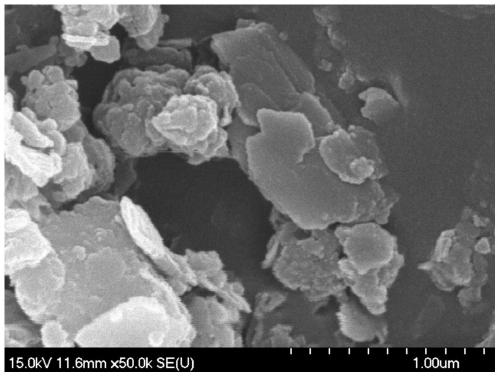

Image

Examples

Embodiment 1

[0057] Preparation of epoxy resin / montmorillonite nanocomposite film: Add 95 parts of epoxy resin E51, 2 parts of organically modified montmorillonite, and 15 parts of reactive diluent 669 into a 250 mL three-necked flask, stir well, and heat up to 80 ° C. Insulate and stir for 2 hours, then ultrasonically disperse at high temperature for 10 minutes, and then vacuum defoam for 10 minutes; after cooling to close to room temperature, add 50 parts of curing agent polyamide 650 and 3 parts of accelerator DMP-30 into the mixture, stir well and coat on The surface of the aluminum sheet was cured at room temperature for 48 hours to prepare an epoxy resin / montmorillonite nanocomposite film.

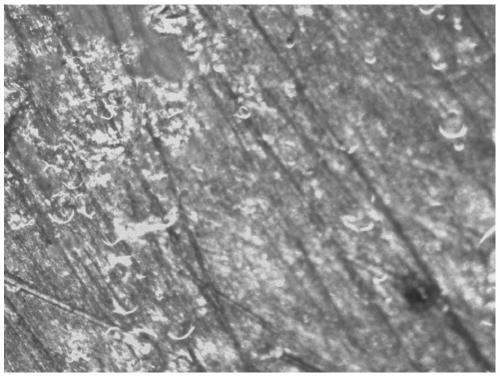

[0058] The SZ61 optical microscope of Olympus Company was used to characterize the epoxy resin / montmorillonite nanocomposite film, and the results were as follows: figure 2 It can be seen from the figure that the addition of organically modified montmorillonite is too little, the film layer is n...

Embodiment 2

[0060] Preparation of epoxy resin / montmorillonite nanocomposite film: Add 100 parts of epoxy resin E51, 3 parts of organically modified montmorillonite, and 15 parts of reactive diluent 669 into a 250 mL three-necked flask, stir well, and heat up to 80 ° C. Insulate and stir for 2 hours, then ultrasonically disperse at high temperature for 10 minutes, and then vacuum defoam for 10 minutes; after cooling to close to room temperature, add 50 parts of curing agent polyamide 650 and 3 parts of accelerator DMP-30 into the mixture, stir well and coat on The surface of the aluminum sheet was cured at room temperature for 48 hours to prepare epoxy resin / montmorillonite nanocomposites.

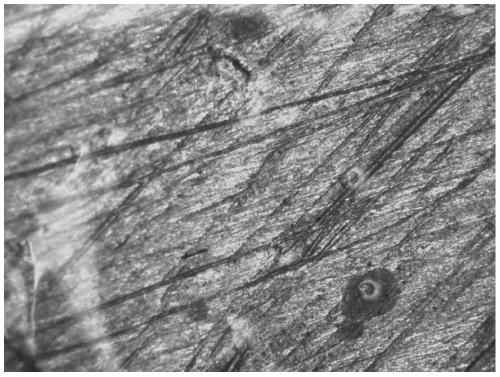

[0061] The SZ61 optical microscope of Olympus Company was used to characterize the epoxy resin / montmorillonite nanocomposite film, and the results were as follows: image 3 It can be seen from the figure that the addition amount of organically modified montmorillonite is more appropriate, and the compo...

Embodiment 3

[0063] Preparation of epoxy resin / montmorillonite nanocomposite film: Add 90 parts of epoxy resin E51, 4 parts of organically modified montmorillonite, and 15 parts of reactive diluent 669 into a 250 mL three-necked flask, stir well, and heat up to 80 ° C. Insulate and stir for 2 hours, then ultrasonically disperse at high temperature for 5 minutes, and then vacuum defoam for 10 minutes; after cooling to close to room temperature, add 50 parts of curing agent polyamide 650 and 3 parts of accelerator DMP-30 into the mixture, stir well and coat on The surface of the aluminum sheet was cured at room temperature for 48 hours to prepare epoxy resin / montmorillonite nanocomposites.

[0064] The SZ61 optical microscope of Olympus Company was used to characterize the epoxy resin / montmorillonite nanocomposite film, and the results were as follows: Figure 4 As shown, it can be seen from the figure that the amount of organically modified montmorillonite added is large, the film layer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com