UV (Ultraviolet) curable coating

A technology for curing coatings and coatings, applied in the field of UV paints, can solve the problems of unfavorable environmental protection, slow curing speed, easy volatilization, etc., and achieve the effects of good flexibility, good hardness, and excellent heat and chemical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation step of the embodiment of the present invention is to add the powder in the formula (such as powdered additives, etc.) , slowly put in epoxy acrylate and ABS resin, disperse for 10-20min, put in photoinitiator, stir and disperse for 35-40min, add the remaining reactive diluent and dispersant, add defoamer, stir evenly, and obtain UV curable coating. The specific formulation is described in the following examples.

[0036] The selected components of the embodiment are as follows: the diluent such as CYTEC, SARTOMER, Changxing, Miki or their mixture; the defoamer such as tego920, tego931 produced by Tego Company or their mixture; the dispersant Such as tego685, tego655 produced by Tego Company or their mixtures; the initiator such as TPO produced by BASF, CIBA 184, 1173 or their mixtures; the pigment is rutile titanium dioxide, such as TR92 of HUNTSMAN.

Embodiment 1

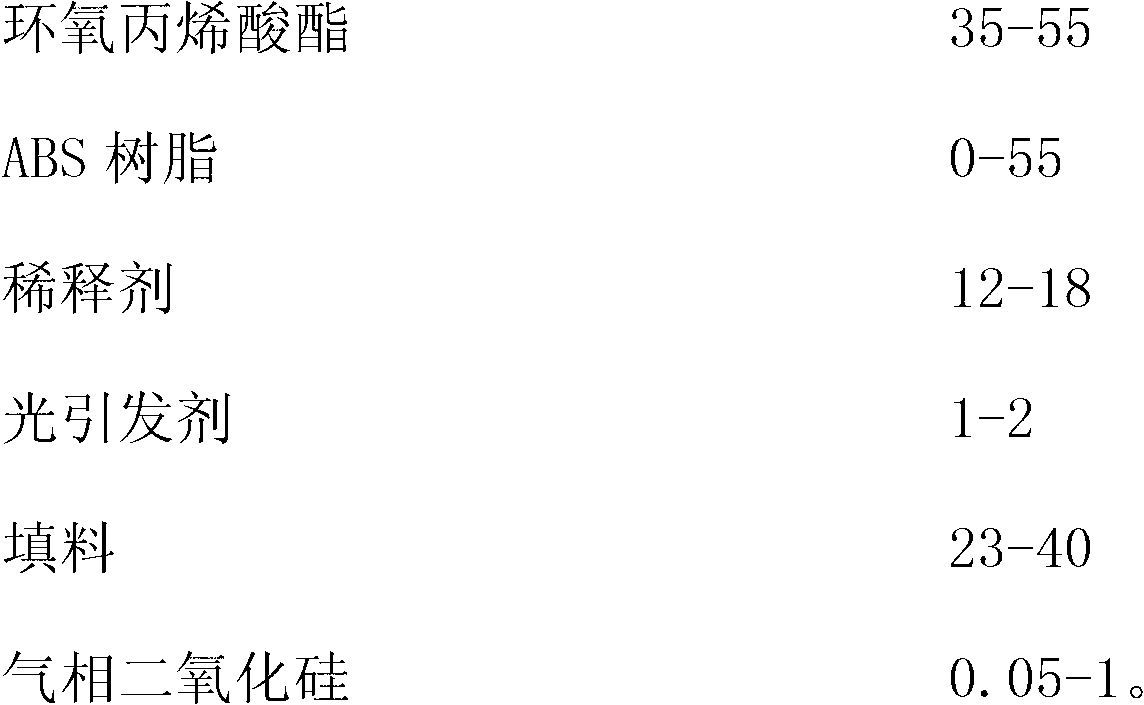

[0038] A kind of UV curable coating, described coating comprises following component by weight part:

[0039]

Embodiment 2

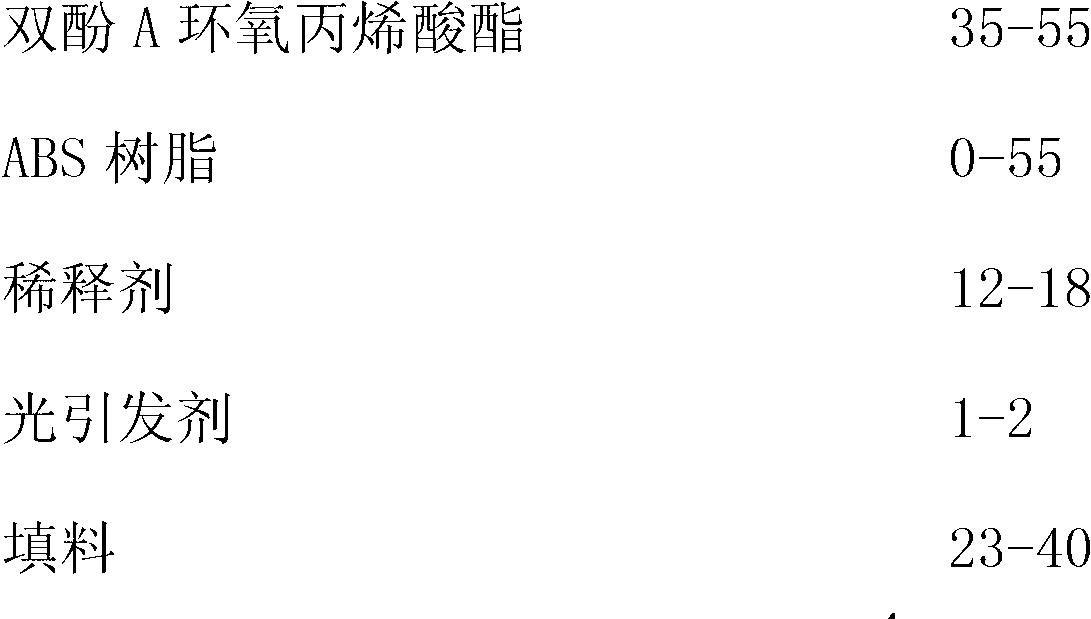

[0041] A kind of UV curable coating, described coating comprises following component by weight part:

[0042]

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com