Glass fiber reinforced PC material capable of being ultrasonically welded and preparation method thereof

An ultrasonic welding and glass fiber technology, applied in the field of PC materials, can solve the problems of easy cracking, large loss of comprehensive mechanical properties, low impact toughness, etc., and achieve the effect of lower melting point, soft appearance and meeting manufacturing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

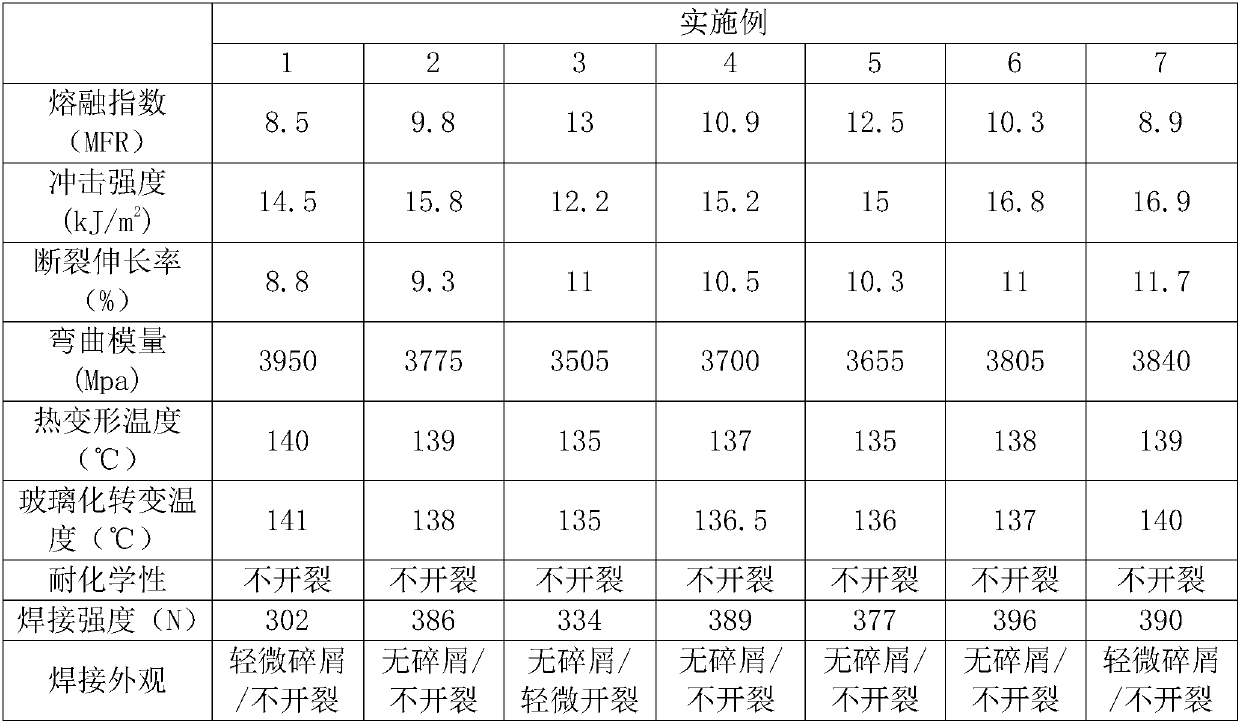

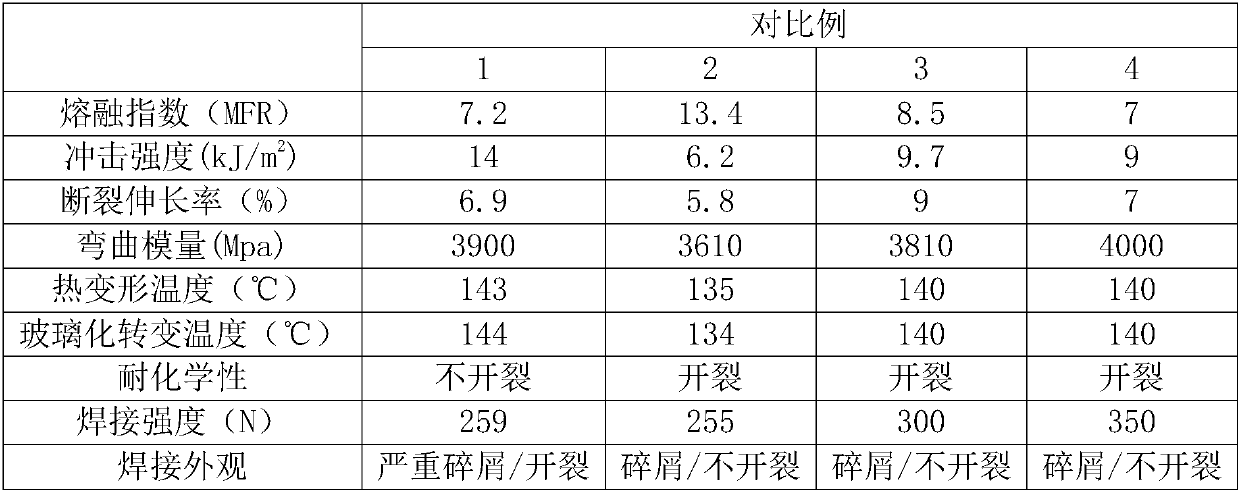

Examples

preparation example 0

[0048] Preparation Example 0: SAN320, purchased from Kumho Sunny, Korea.

preparation example 1

[0049] Preparation Example 1: The preparation process of SAN-A is as follows:

[0050] (1) Mix 65wt% aromatic hydrocarbon monomers and 35wt% acrylonitrile monomers to form a 100% monomer mixture, and stir evenly;

[0051] (2) dissolving cycloalkenes accounting for 15% by weight of the monomer mixture in the above-mentioned monomer mixture, the cycloalkenes being selected from cyclopentene;

[0052] (3) Then add n-hexane accounting for 10wt% of the monomer mixture and benzoyl peroxide accounting for 0.1wt% of the monomer mixture, mix and add in the reactor;

[0053] (4) Finally, heat to 100°C, pressure 0.5Mpa, continue to stir and carry out polymerization, until the solid content in the polymerization product is 93.5wt%, stop polymerization, devolatilization, obtain styrene-acrylonitrile-cycloolefin heat-resistant copolymer, weight The average molecular weight is 30,000, and its melt flow rate MI at 220°C is 20g / 10min;

[0054] (5) The above-mentioned styrene-acrylonitrile-cy...

preparation example 2

[0055] Preparation Example 2: The preparation process of SAN-B is as follows:

[0056] (1) Mix 65wt% aromatic hydrocarbon monomers and 35wt% acrylonitrile monomers to form a 100% monomer mixture, and stir evenly;

[0057] (2) dissolving cycloalkene accounting for 5 wt% of the monomer mixture content and N-substituted maleimide accounting for 10 wt% of the monomer mixture content in the monomer mixture, wherein the cycloalkene is selected from cyclohexene;

[0058] (3) Then add n-hexane accounting for 10.0wt% of the monomer mixture and benzoyl peroxide accounting for 0.1wt% of the monomer mixture, mix and add in the reactor;

[0059] (4) Finally, heat to 120°C, pressure 0.4Mpa, continue to stir and carry out polymerization until the solid content in the polymerization product is 91.8wt%, stop polymerization, devolatilization, and obtain styrene-acrylonitrile-N-phenylmaleimide Amine-cycloolefin with a weight average molecular weight of 20000 and a melt flow rate MI of 40g / 10min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com