Preparation method of polymeric material for tribromobenzoic acid

A technology of tribromobenzoic acid and polymer materials, which is applied in the field of preparation of polymer materials for tribromobenzoic acid, can solve the problems of tribromostyrene, complicated operation steps, and large energy consumption, and achieve stable and long-lasting adsorption effect , the effect of large amount of impurities and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

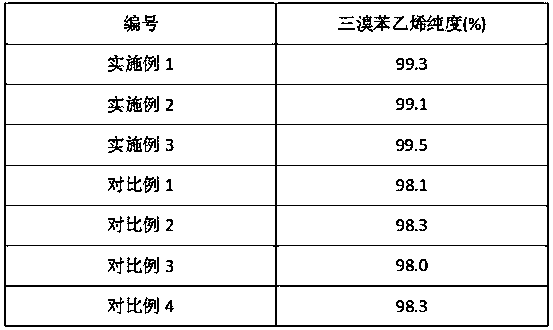

Examples

Embodiment 1

[0021] In the reaction kettle, add 100Kg of hydroxyapatite, 2Kg of 1,1,1,3,3,3-hexafluoroisopropyl acrylate, 1,1'-benzenesulfonyl-4,4'-diallyl ether 1.5Kg, 3-(trimethylsilyl)-4-pentenoic acid methyl ester 3Kg, (3-oxo-1,3-dihydroisobenzofuran-1-yl) dimethyl phosphate 0.05Kg, Cyclopentadienetricarbonylrhenium 0.3Kg, ammonium persulfate 0.3Kg, sodium dodecylbenzenesulfonate 0.75Kg, water 400Kg, then pass high-purity nitrogen gas to remove oxygen by bubbling; 80°C, react for 15h to obtain polymer , dried and pulverized to obtain a polymeric material for tribromobenzoic acid.

Embodiment 2

[0023] In the reaction kettle, add 100Kg of hydroxyapatite, 1Kg of 1,1,1,3,3,3-hexafluoroisopropyl acrylate, 1,1'-benzenesulfonyl-4,4'-diallyl ether 1Kg, 3-(trimethylsilyl)-4-pentenoic acid methyl ester 1Kg, (3-oxo-1,3-dihydroisobenzofuran-1-yl) dimethyl phosphate 0.01Kg, ring Pentadiene tricarbonyl rhenium 0.1Kg, ammonium persulfate 0.1Kg, sodium dodecylbenzenesulfonate 0.5Kg, water 300Kg, then pass through high-purity nitrogen to remove oxygen by bubbling; 70°C, react for 20h to obtain a polymer, After drying and crushing, a polymeric material for tribromobenzoic acid is obtained.

Embodiment 3

[0025] In the reaction kettle, add 100Kg of hydroxyapatite, 5Kg of 1,1,1,3,3,3-hexafluoroisopropyl acrylate, 1,1'-benzenesulfonyl-4,4'-diallyl ether 5Kg, 3-(trimethylsilyl)-4-pentenoic acid methyl ester 5Kg, (3-oxo-1,3-dihydroisobenzofuran-1-yl) dimethyl phosphate 0.1Kg, ring Pentadienetricarbonylrhenium 0.5Kg, ammonium persulfate 0.5Kg, sodium dodecylbenzenesulfonate 2Kg, water 800Kg, then pass high-purity nitrogen gas to remove oxygen by bubbling; 100°C, react for 10h, obtain polymer, dry and pulverizing to obtain a polymeric material for tribromobenzoic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com