Highly hydrophilic and highly wear-resistant organic/inorganic hybrid photocurable coating composition

A technology of high hydrophilicity, high wear resistance, light-curing coatings, applied in polyurea/polyurethane coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of complex process, long time required and general anti-fog performance Achieve low viscosity, save energy, increase interaction

Inactive Publication Date: 2017-10-24

SHANGHAI WEIKAI CHEM +2

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The hardness of the coating is greater than 2H, the wear resistance is good, the anti-fog performance is relatively general, the curing process takes a long time, and it needs to be cured in sections (50 ° C ~ 120 ° C), and the process is relatively complicated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~5

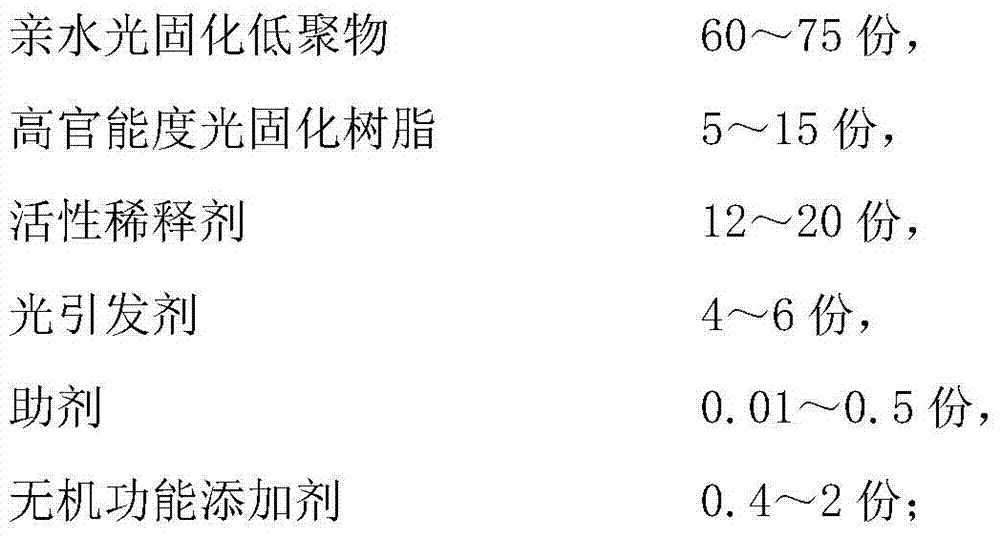

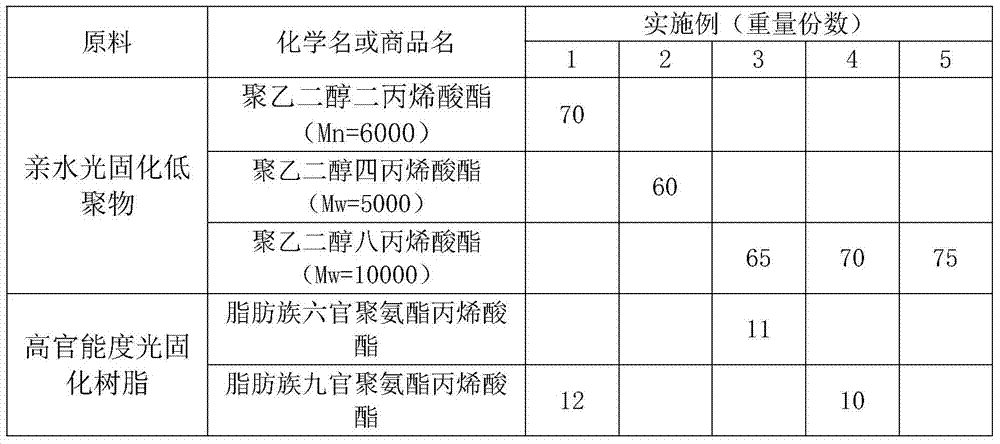

[0026] Examples 1-5 relate to a highly hydrophilic and highly wear-resistant photocurable coating composition for glass, including the components and parts by weight shown in Table 1.

[0027] Using glass as the base material, pour the paint into the heating trough, heat it to 70°C, use three-roller gluing, and coat the paint on the glass surface to control the film thickness to 1.2 microns. 500mJ / cm 2 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a highly hydrophilic and highly wear-resistant organic / inorganic hybrid photocurable coating composition; the composition comprises 60-75 parts of a hydrophilic photocurable oligomer and 5-15 parts of a high-functionality photocurable resin , 12-20 parts of reactive diluent, 4-6 parts of photoinitiator, 0.01-0.5 part of auxiliary agent, 0.4-2 parts of inorganic functional additive; the inorganic functional additive is selected from polyvinyl silsesquioxane, methyl Acryloxysilsesquioxane, Acryloxysilsesquioxane. The UV-curable hydrophilic coating provided by the invention can be applied to the surface of glass, and has excellent hydrophilicity and physical properties after curing, as well as good adhesion, water resistance, acid resistance and abrasion resistance.

Description

technical field [0001] The invention belongs to the field of ultraviolet curing coatings, in particular to a highly hydrophilic and highly wear-resistant organic / inorganic hybrid photocuring coating composition. Background technique [0002] With the improvement of people's living standards, people have higher requirements for the performance of some traditional materials, among which there are higher requirements for the transparency of some transparent materials, such as glass, in high humidity or water environment . Among them, it is widely used in automobile glass and bathroom glass / mirror. On the car glass, the front and rear windshields can have wipers to ensure that it will not affect the line of sight in rainy days, but the rearview mirror and the side window glass of the car do not have this function, so that the surfaces of these two parts will be blurred in rainy days. A large number of water droplets adhere to the surface, which affects the driver's observation...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D175/14C09D163/00C09D167/06C09D4/02C09D7/12

Inventor 虞明东王世哲李桐蒋天龙

Owner SHANGHAI WEIKAI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com