Easy-to-clean coating for metal surface and preparation method of easy-to-clean coating

A metal surface, easy-to-clean technology, used in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as environmental pollution and application limitations, and achieve the effects of simple operation, long service life and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

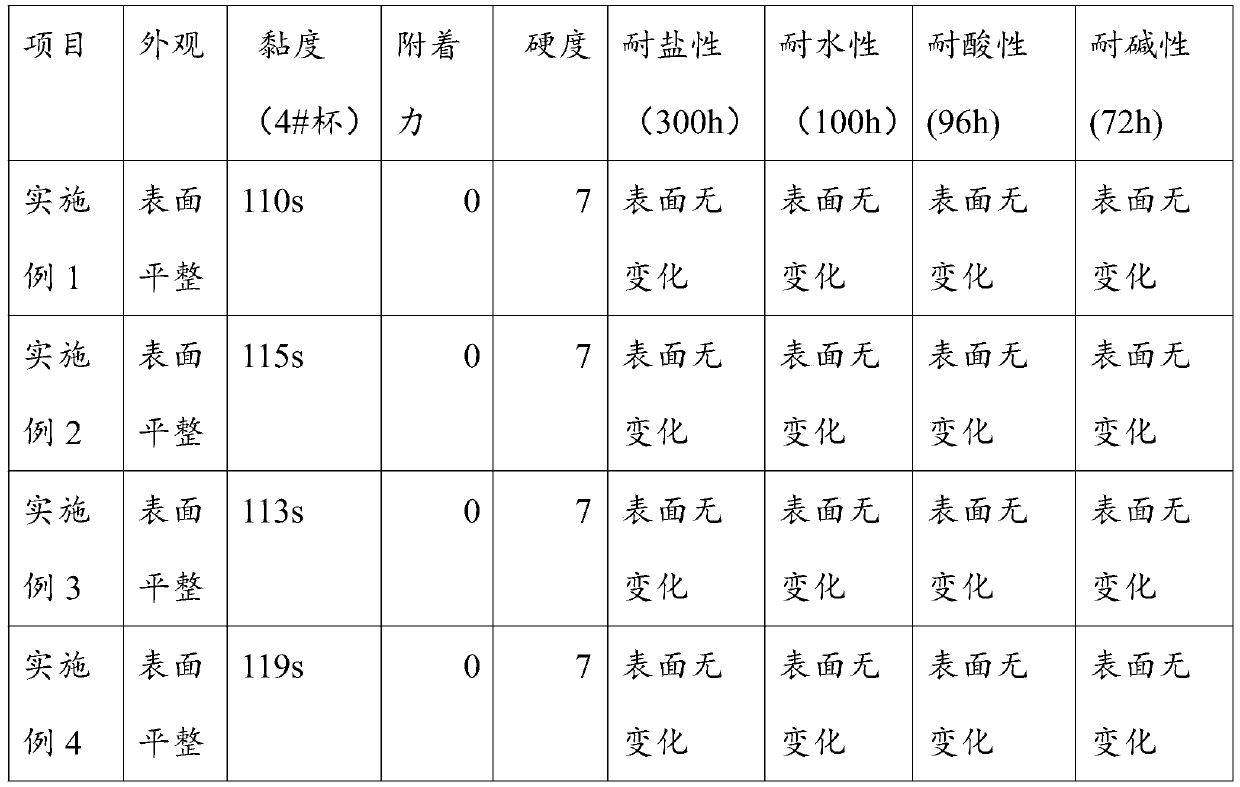

Examples

Embodiment 1

[0027] A kind of easy-to-clean paint for metal surfaces provided by the invention is composed of the following components by weight: modified epoxy resin emulsion 100g, lithium silicate 13g, KH-560 silane coupling agent 0.9g, DOW U.S. Dow DER 324 reactive diluent 15g, alcohol ester twelve 1g, modified nano CaCO 3 1g, German BYK-325 3g, German BASF water-based defoamer FoamStarST2292 1.2g, Dow Chemical NP-10 water-based paint wetting agent 0.5g, German BYK BYK-AQUACER-15471g.

[0028] Described modified epoxy resin emulsion is made through the following steps:

[0029] 1) Weigh 10g of epoxy resin, add a mixed solvent, stir and heat up to 110°C, add 0.3g of phosphoric acid, control the addition for 3 minutes, and continue the reaction;

[0030] The mixed solvent is a mixture of furfural and n-butanol in a volume ratio of 1:1

[0031] 2) Slowly add 0.5g of styrene, 0.4g of acrylic acid, 0.3g of butyl acrylate, 0.3g of tert-butyl peroxybenzoate, react at 105°C for 6h, and add t...

Embodiment 2

[0034] A kind of easy-to-clean paint for metal surfaces provided by the invention is composed of the following components by weight: modified epoxy resin emulsion 120g, lithium silicate 10g, KH-560 silane coupling agent 1.2g, DOW U.S. Dow DER 324 reactive diluent 12g, dipropylene glycol methyl ether 2g, modified nano-CaCO 3 2g, German BYK-325 1g, German BASF water-based defoamer FoamStarST2292 2.5g, Dow Chemical NP-10 water-based paint wetting agent 0.5g, German BYK BYK-AQUACER-15471.

[0035] Described modified epoxy resin emulsion is made through the following steps:

[0036] 1) Weigh 10g of epoxy resin, add a mixed solvent, stir and heat up to 120°C, add 0.2g of phosphoric acid, control the addition for 3 minutes, and continue the reaction;

[0037] The mixed solvent is a mixture of furfural and n-butanol in a volume ratio of 1:1

[0038] 2) Slowly add 0.3g of styrene, 0.4g of acrylic acid, 0.3g of butyl acrylate, 0.3g of tert-butyl peroxybenzoate, react at 115°C for 5h,...

Embodiment 3

[0041] A kind of easy-to-clean paint for metal surfaces provided by the invention is composed of the following components by weight: modified epoxy resin emulsion 115g, lithium silicate 12g, KH-560 silane coupling agent 1g, DOW U.S. Dow DER 324 reactive diluent 13g, dipropylene glycol methyl ether 1.5g, modified nano-CaCO 3 1.2g, German BYK-325 2g, German BASF water-based defoamer FoamStarST2292 1.8g, Dow Chemical NP-10 water-based paint wetting agent 0.4g, German BYK-AQUACER-15471.2g.

[0042] Described modified epoxy resin emulsion is made through the following steps:

[0043] 1) Weigh 10g of epoxy resin, add a mixed solvent, stir and heat up to 115°C, add 0.25g of phosphoric acid, control the addition for 3 minutes, and continue the reaction;

[0044] The mixed solvent is a mixture of furfural and n-butanol in a volume ratio of 1:1

[0045] 2) Slowly add 0.4g of styrene, 0.4g of acrylic acid, 0.4g of butyl acrylate, 0.25g of tert-butyl peroxybenzoate, react at 110°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com