Rust-proof coating

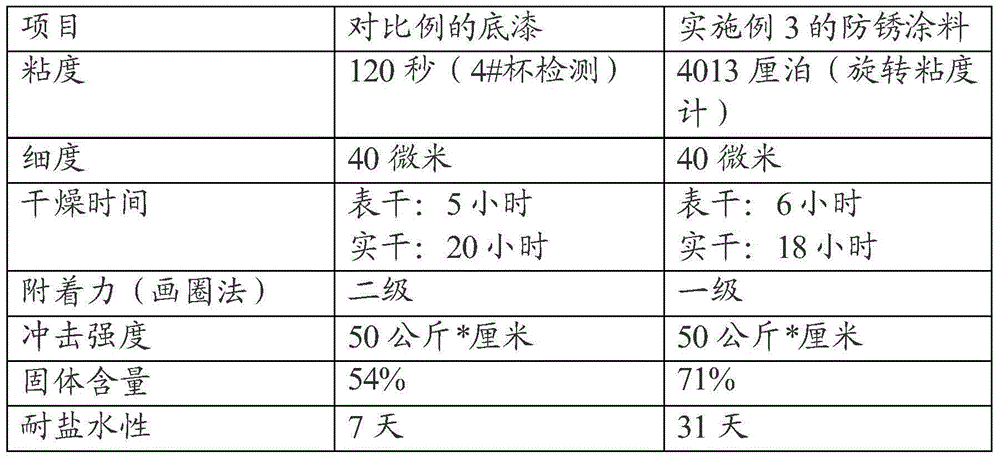

An anti-rust coating and epoxy resin technology, applied in the field of coatings, can solve the problems of unsatisfactory anti-rust performance, can not meet the needs of customers with high anti-corrosion performance, etc., and achieve the effect of good thixotropic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of above-mentioned antirust paint, comprises the following steps:

[0060] In parts by weight, 18-22 parts of the first epoxy resin, 10-15 parts of magnet powder, 5-8 parts of iron oxide red, 3-6 parts of zinc phosphate, 3-4 parts of zinc powder and 0.1-0.2 parts are dispersed agent, ball milling to disperse until the fineness reaches 35 microns, discharge to obtain a mixture, and pour the mixture into a slurry mixing tank;

[0061] Add 12-15 parts of diluent and 18-24 parts of second epoxy resin into the mixing tank, stir evenly, and when the powder degree reaches a rotational viscosity of 4000 centipoise, discharge to obtain component A;

[0062] Weigh 56-62 parts of the first amine curing agent, add 20-30 parts of ethanol and 12-18 parts of the second amine curing agent under stirring, and stir evenly to obtain component B;

[0063] The component A and the component B are mixed according to a weight ratio of 5:1 to obtain an antirust paint.

Embodiment 1

[0066] A kind of antirust paint, comprising A component and B component that weight ratio is 5:1, by weight, A component comprises:

[0067] 18 parts of E44 resin (first epoxy resin), 18 parts of E20 resin (second epoxy resin) with a mass fraction of 60%, 10 parts of magnet powder, 2 parts of iron oxide red, 3 parts of zinc phosphate, and 1 part of zinc powder , 0.1 parts of dispersant, 0.2 parts of auxiliary agent and 12 parts of diluent;

[0068] Component B includes:

[0069] Hexamethylenediamine (first amine curing agent) 56 parts, 651 polyamide (second amine curing agent) 12 parts, ethanol 20 parts.

[0070] The preparation method of above-mentioned antirust paint, comprises the following steps:

[0071] Stir 18 parts of E44 resin, 10 parts of magnet powder, 5 parts of red iron oxide, 3 parts of zinc phosphate, 3 parts of zinc powder and 0.1 part of dispersant until the fineness reaches 35 microns, and discharge the mixture to obtain the mixture and pour it into the sea...

Embodiment 2

[0076] A kind of antirust paint, comprising A component and B component that weight ratio is 5:1, by weight, A component comprises:

[0077] E44 resin (first epoxy resin) 18 parts E20 resin (second epoxy resin) 24 parts, magnet powder 15 parts, iron oxide red 10 parts, zinc phosphate 6 parts, zinc powder 6 parts, dispersant 0.2 parts, auxiliary 0.3 parts of agent and 15 parts of diluent;

[0078] Component B includes:

[0079] Hexamethylenediamine (first amine curing agent) 62 parts, 651 polyamide (second amine curing agent) 18 parts, ethanol 30 parts.

[0080] The preparation method of above-mentioned antirust paint, comprises the following steps:

[0081] Stir the E44 resin, magnet powder, red iron oxide, zinc phosphate, zinc powder and dispersant until the fineness reaches 35 microns, discharge to obtain the mixture, and pour it into the mixing tank;

[0082] Add additives, E20 resin and diluent to the paste, stir evenly, and when the powder degree reaches a rotational v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com