Anticorrosion paint and preparation method thereof

A technology for anti-corrosion coatings and raw materials, applied in the field of coatings, can solve the problems of poor coating performance, complicated preparation methods, unfavorable industrial production and application, etc., and achieve the effects of long service life, simple preparation, and synergistic promotion of performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

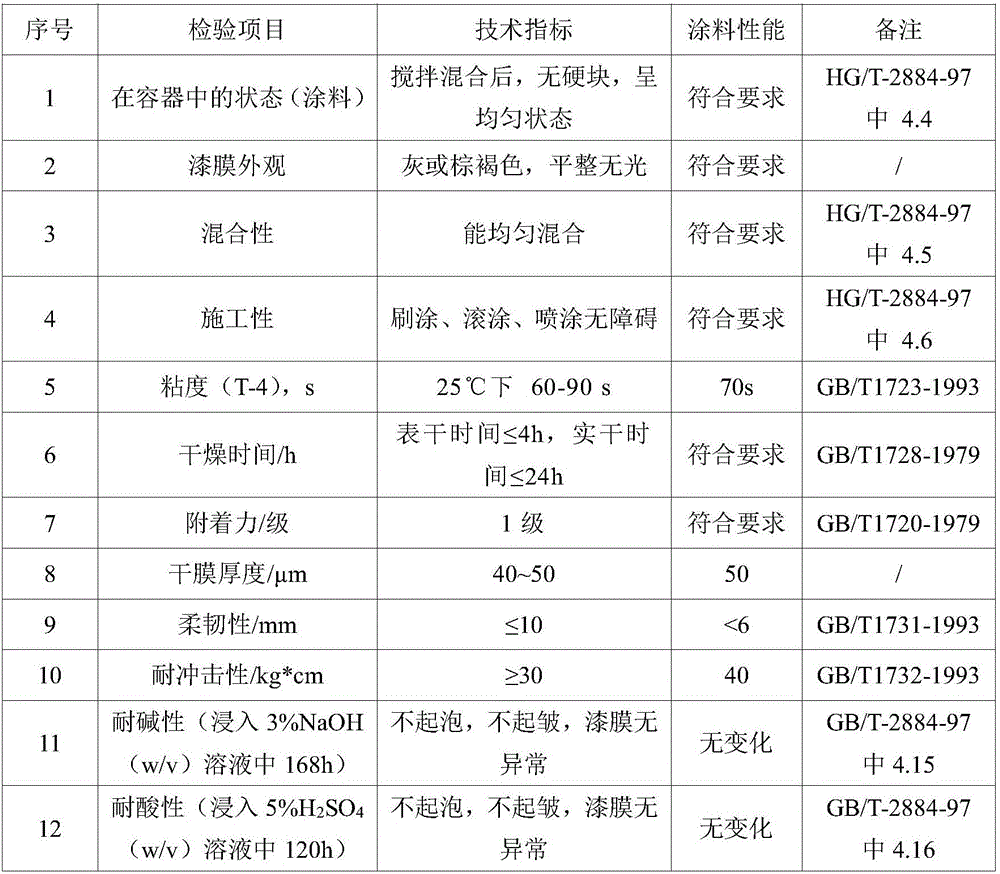

Examples

Embodiment 1

[0019] An anti-corrosion coating, consisting of the following raw materials in parts by weight: 33 parts of epoxy resin, 12 parts of thinner, 0.5 parts of dispersant, 10 parts of toughening agent, 35 parts of micaceous iron oxide, 2 parts of talcum powder, and 5 parts of titanium dioxide , 2.5 parts of fumed silica and 13.2 parts of curing agent, the diluent xylene and n-butanol, the volume ratio of xylene and n-butanol is 7:3, and the toughening agent is hyperbranched epoxy toughening agent CYH277 , the curing agent is a modified polyamide epoxy curing agent D3014, the dispersant is polycarboxylate sodium salt, and the particle size of the talcum powder is 800 mesh.

[0020] The preparation method of the anticorrosion coating described in the present embodiment may further comprise the steps:

[0021] (1) Prepare raw materials according to the proportion, add the diluent into the epoxy resin in the mixer reactor, set the rotating speed at 1000r / min, stir for 20min, then add t...

Embodiment 2

[0024] An anti-corrosion coating, consisting of the following raw materials in parts by weight: 35 parts of epoxy resin, 15 parts of thinner, 0.6 parts of dispersant, 12 parts of toughening agent, 38 parts of micaceous iron oxide, 1 part of talcum powder, and 4 parts of titanium dioxide , 3 parts of fumed silica and 12 parts of curing agent, the diluent xylene or n-butanol, the toughening agent is hyperbranched epoxy toughening agent CYH277, and the curing agent is modified polyamide epoxy Curing agent D3014, the dispersant is polycarboxylate, and the particle size of the talcum powder is 800 mesh.

[0025] The preparation method of the anticorrosion coating described in the present embodiment may further comprise the steps:

[0026] (1) Prepare raw materials according to the proportion, add the diluent into the epoxy resin in the mixer reactor, set the rotating speed at 1000r / min, stir for 30min, then add the dispersant, toughening agent, mica oxidation Iron, fumed silica, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com