Insulating heat-dissipating coating and preparation method of same

A technology of heat-dissipating coatings and coatings, applied in the direction of coatings, etc., to achieve the effects of less pollution, guaranteed use effects, and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

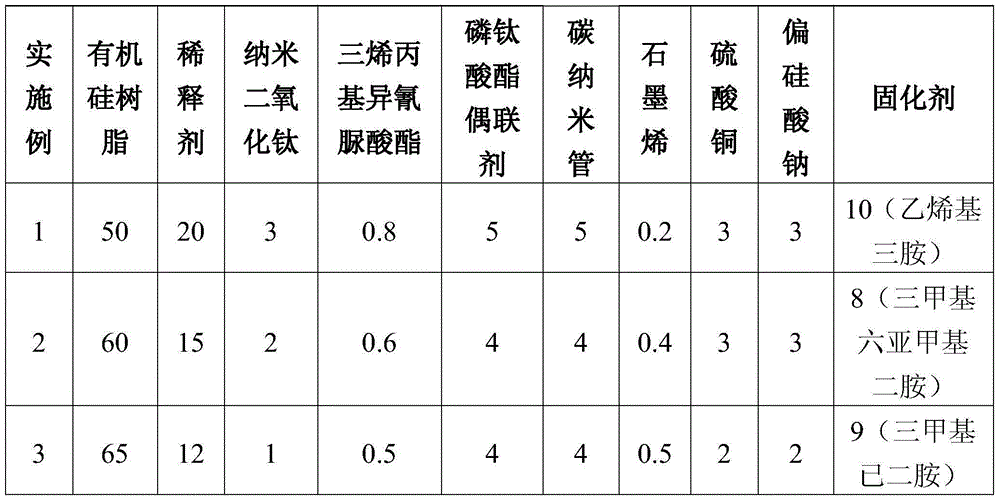

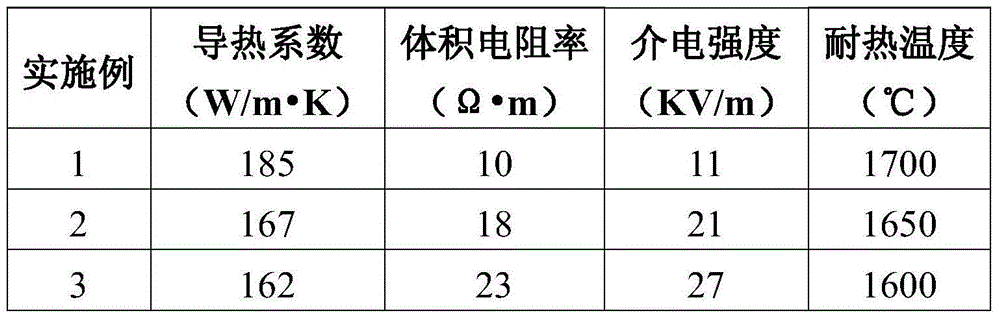

[0017] The technical solutions of the present invention will be further described below through specific examples.

[0018] An insulating heat-dissipating coating, which is prepared from the following raw materials in parts by weight:

[0019] Silicone resin 50~65, diluent 12~20, nano titanium dioxide 1~3, triallyl isocyanurate 0.5~0.8, phosphotitanate coupling agent 4~5, carbon nanotube 4~5, Graphene 0.2-0.5, copper sulfate 2-3, sodium metasilicate 2-3, curing agent 8-10.

[0020] The present invention improves the problem of poor mixing of thermally conductive fillers in heat-dissipating coatings by adding carbon nanotubes, because the addition of carbon nanotubes is conducive to its dispersion in the resin, and can thus form an effective heat-conducting network in the resin, reducing the interface gap. The contact thermal resistance between them can improve the thermal conductivity of the coating and prolong its service life.

[0021] In existing heat dissipation coatings...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com