Organic/inorganic hybrid hardening agent, and preparation method and application thereof

A hardening agent and inorganic technology, applied in the field of wear-resistant and scratch-resistant protective coatings, can solve the problems of affecting the transparency of the coating, failing to achieve performance, and difficulty in dispersing, and achieve simple manufacturing process, high production efficiency, and limited dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

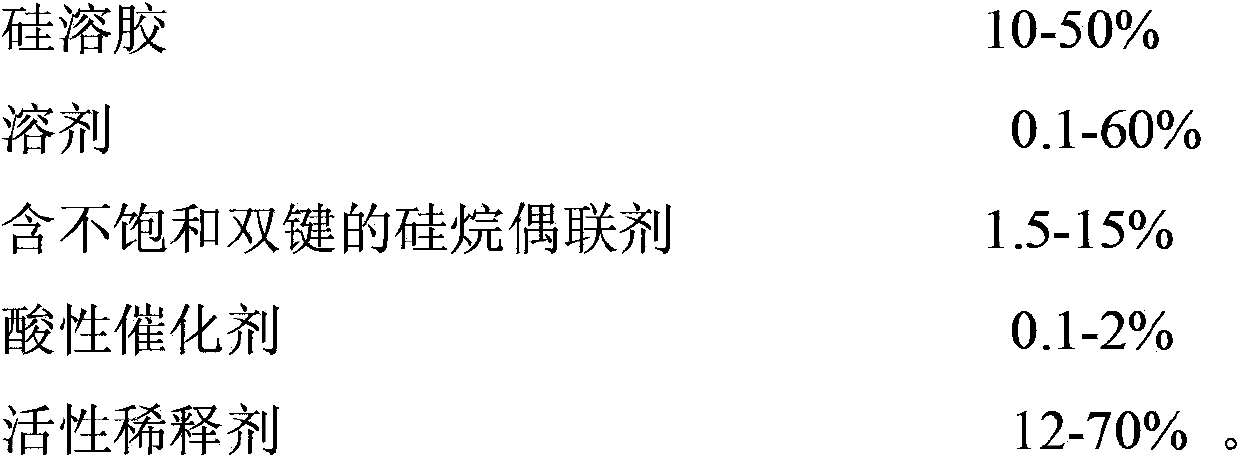

[0031] The organic / inorganic hybrid hardening agent provided in this embodiment is made of the following raw materials in weight percentage:

[0032]

[0033] The preparation method of the aforementioned organic / inorganic hybrid hardening agent comprises the following steps:

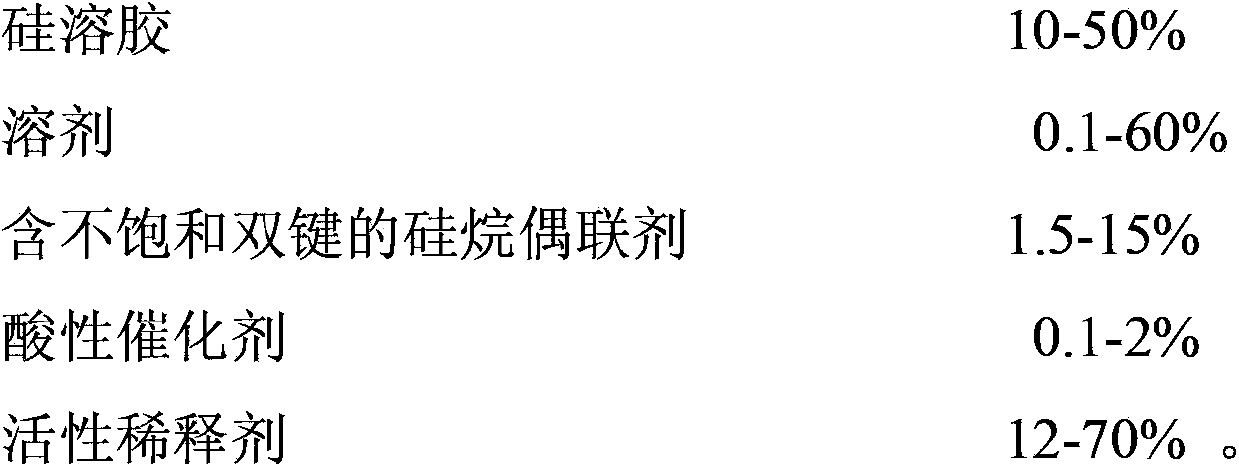

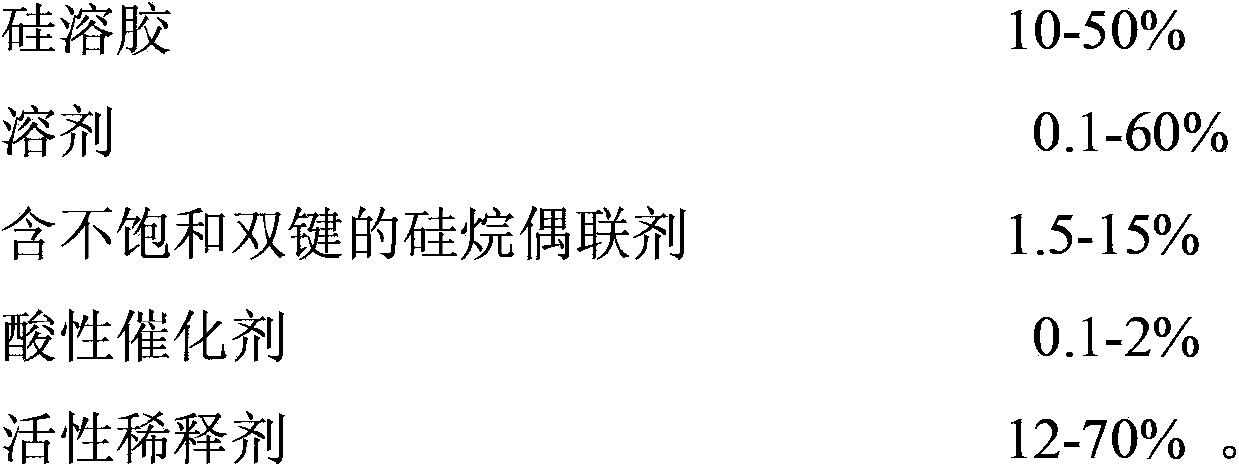

[0034] (1) Prepare raw materials: each component of the raw material and its weight percentage are as follows:

[0035]

[0036] (2) Preparation of organic / inorganic hybrid hardening agent:

[0037] First, add silica sol and solvent into the three-necked flask, and then add the silane coupling agent containing unsaturated double bonds dropwise. Secondly, use an acidic catalyst to adjust the pH value to 3-4. Under certain conditions, after reacting for 3 to 6 hours, add a reactive diluent. Finally, add the above mixed solution into a single-necked flask. , continue to evaporate until no distillate is distilled out, then filter through gauze, bottle and age for 24 hours to obtain a solvent-free org...

Embodiment 2

[0046] The organic / inorganic hybrid hardening agent, preparation method and application provided in this example are basically the same as those in Example 1, except that:

[0047]First prepare the organic / inorganic hybrid hardening agent: add 200g of silica sol and 108.6g of ethanol to a 500ml three-necked flask, add 7.4g of vinyltrimethoxysilane dropwise, adjust the pH to 3-4 with 7.1g of HAc, and stir After reacting for 3-6 hours, add 72.4g of 1,6-hexanediol diacrylate, transfer the above mixture to a one-necked flask, distill under reduced pressure at 80°C until a white solid appears, add 32.6g of ethanol and continue to evaporate until there is no distillate distilled. Filter through gauze, bottle and age for 24 hours to obtain a solvent-free organic / inorganic hybrid hardening agent.

[0048] Preparation of UV Curable Nanocomposite Coating UV-V with the Prepared Organic / Inorganic Hybrid Hardener 1 : 16g of organic / inorganic hybrid hardening agent, 19.2g of polyurethane ...

Embodiment 3

[0050] The organic / inorganic hybrid hardening agent provided in this example and its preparation method and application are basically the same as those in Examples 1 and 2, except that:

[0051] First prepare the organic / inorganic hybrid hardening agent: add 200g of silica sol and 108.6g of ethanol to a 500ml three-necked flask, add 12.4g of γ-methacryloxytrimethoxysilane dropwise, and adjust the pH to 3 with 7.1g of HAc -4. After stirring and reacting for 3-6 hours, add 72.4g of 1,6-hexanediol diacrylate, transfer the above mixed solution to a one-necked flask, distill under reduced pressure at 80°C until a white solid appears, add 32.6g of ethanol and continue Evaporate until no distillate distills. Filter through gauze, bottle and age for 24 hours to obtain the organic / inorganic hybrid hardening agent.

[0052] Preparation of UV Curable Nanocomposite Coatings UV-K with the Prepared Organic / Inorganic Hybrid Hardener 1 .

[0053] Mix and stir 16g of organic / inorganic hybri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com