Power mode Surface Mounted Device (SMD) semiconductor component

A semiconductor and power-type technology, applied in the field of power-type SMD semiconductor components, can solve the problems of withstand power and small current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

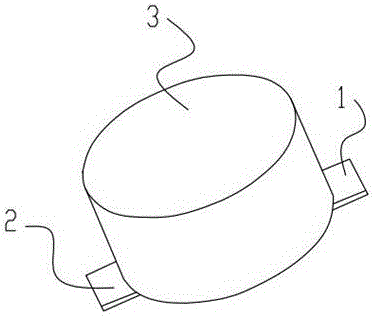

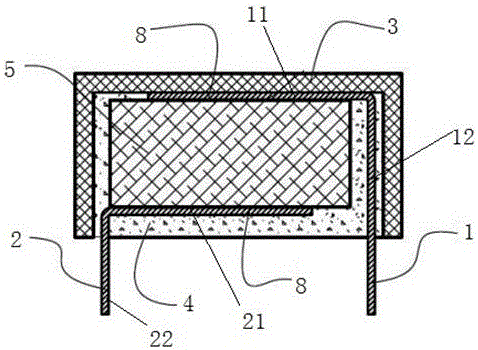

[0033] like figure 2 As shown, the embodiment of the present invention discloses a power chip semiconductor element, including a varistor chip 5, the upper electrode sheet 1 is welded on the upper surface of the varistor chip 5 through a solder sheet 8, and the lower electrode sheet 2. Solder the lower surface of the piezoresistor chip 5 through a solder sheet 8; the outer side of the piezoresistor chip 5 is provided with a container-shaped flame-retardant insulating shell 3, and the gap between the shell and the piezoresistor chip 5 is Filled with encapsulation filler 4, the free ends of the upper electrode sheet 1 and the lower electrode sheet 2 extend out of the casing, serving as two connecting pins of the semiconductor element.

[0034] like figure 2 , 6 As shown, the upper electrode sheet 1 includes a first horizontal welding sheet 11 and a first connecting sheet 12 . The first horizontal soldering piece 11 is welded on the upper surface of the combination chip, the...

Embodiment 2

[0039] This embodiment is different from the first embodiment in that the specific forms of the upper electrode sheet 1 and the lower electrode sheet 2 are different. The first embodiment is a direct plug-in pin component, and the second embodiment is a patch pin component. Specifically, such as image 3 As shown, the upper electrode sheet 1 includes a first horizontal welding sheet 11 and a first connecting sheet 12, the first horizontal welding sheet 11 is welded on the upper surface of the combined chip, and the first connecting sheet 12 includes a first connecting sheet 12 A vertical connection part 121 and a first horizontal connection part 122, the upper end of the first vertical connection part 121 is fixedly connected with the first horizontal welding piece 11, and the lower end of the first vertical connection part 121 is located at the Outside the housing, it is fixedly connected with the first horizontal connection portion 122, and the first horizontal connection po...

Embodiment 3

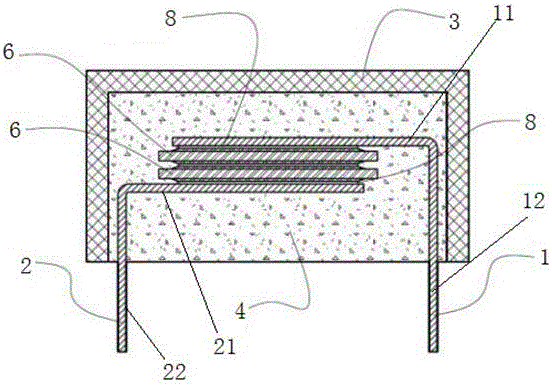

[0041] like Figure 4 As shown, the embodiment of the present invention discloses a power chip semiconductor element, including a combination chip, and the combination chip includes two TVS chips 6 stacked together on top and bottom. The upper and lower surfaces of the TVS diode chip 6 are provided with a conductive nickel layer, between the TVS diode chip 6 and the TVS diode chip 6 and between the upper electrode sheet 1 and the lower electrode sheet 2 and the TVS diode chip 6 are welded through solder sheet 8. The outer side of the combined chip is provided with a container-shaped flame-retardant insulating shell 3, and an encapsulation filler 4 is filled between the shell and the combined chip, and the free ends of the upper electrode sheet 1 and the lower electrode sheet 2 extend to the Outside the housing, as the two connecting pins of the semiconductor element.

[0042] like Figure 4 , 6 As shown, the upper electrode sheet 1 includes a first horizontal welding sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com