Low-density flame retardant polyurethane hard foam plastic and preparation method thereof

A rigid foam, low-density technology, applied in the field of low-density flame-retardant polyurethane rigid foam and its preparation, can only process dark-colored products; others such as graphite, red phosphorus, molybdenum disulfide, metal powder And industrial slag itself has problems such as color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

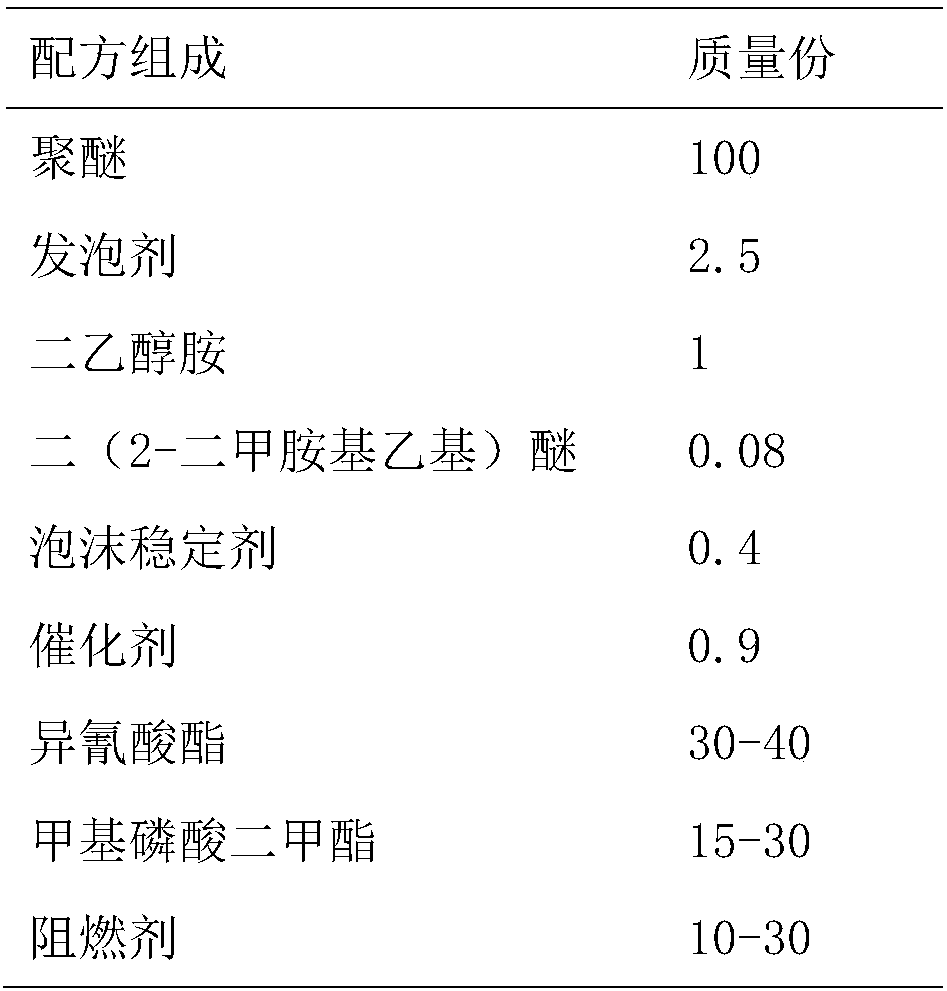

Method used

Image

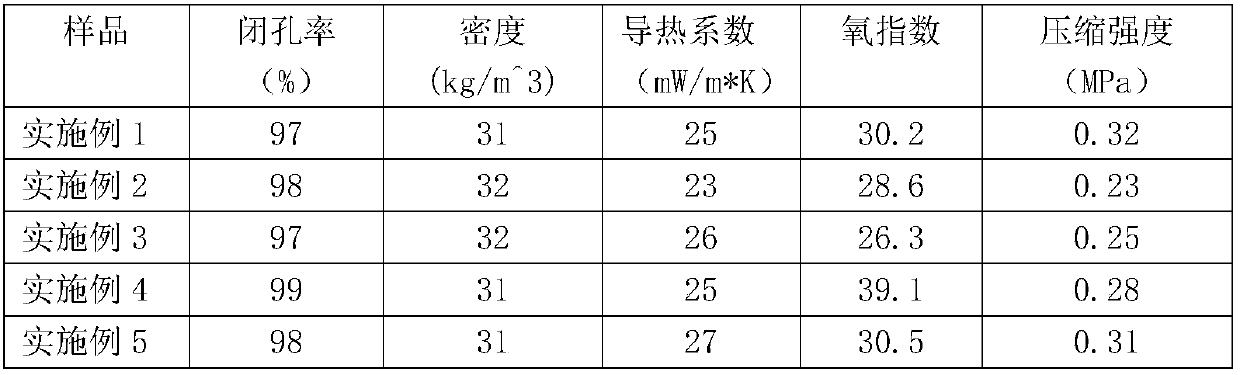

Examples

Embodiment 1

[0019] Control the ambient temperature at 20-25°C, mix 100 parts by weight of polyether, 2.5 parts by weight of water, 1 part by weight of diethanolamine, 0.08 parts by weight of bis(2-dimethylaminoethyl) ether, 0.4 parts by weight of silicon foam stabilizer , 0.9 parts by weight of stannous octoate, 30 parts by weight of isocyanate, 20 parts by weight of dimethyl methyl phosphate, and 30 parts by weight of decabromodiphenyl ether are quickly poured into the barrel at a stirring speed of 2900r / min, and stirred for 9-10s to obtain Combined material, quickly pour the combined material into a mold heated to 40-45°C and cover the mold. Curing is carried out at 70-90°C. After aging, take out the plate and place it flat at 10-40°C for more than 12 hours.

Embodiment 2

[0021] Control the ambient temperature at 20-25°C, mix 100 parts by weight of polyether, 2.5 parts by weight of water, 1 part by weight of diethanolamine, 0.08 parts by weight of bis(2-dimethylaminoethyl) ether, 0.4 parts by weight of silicon foam stabilizer , 0.9 parts by weight of stannous octoate, 40 parts by weight of isocyanate, 30 parts by weight of dimethyl methyl phosphate, and 20 parts by weight of decabromodiphenyl ether are quickly poured into the barrel at a stirring speed of 2900r / min, and stirred for 9-10s to obtain Combined material, quickly pour the combined material into a mold heated to 40-45°C and cover the mold. Curing is carried out at 70-90°C. After aging, take out the plate and place it flat at 10-40°C for more than 12 hours.

Embodiment 3

[0023] Control the ambient temperature at 20-25°C, mix 100 parts by weight of polyether, 2.5 parts by weight of water, 1 part by weight of diethanolamine, 0.08 parts by weight of bis(2-dimethylaminoethyl) ether, 0.4 parts by weight of silicon foam stabilizer , 0.9 parts by weight of stannous octoate, 30 parts by weight of isocyanate, 15 parts by weight of dimethyl methyl phosphate, and 10 parts by weight of decabromodiphenyl ether are quickly poured into the barrel at a stirring speed of 2900r / min, and stirred for 9-10s to obtain Combined material, quickly pour the combined material into a mold heated to 40-45°C and cover the mold. Curing is carried out at 70-90°C. After aging, take out the plate and place it flat at 10-40°C for more than 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com