High-strength flame-retardant anti-static pipeline

A flame-retardant, anti-static, high-strength technology, used in pipeline protection, pipeline damage/wear prevention, pipes, etc., can solve problems such as poor anti-static performance, affecting production, easy deformation, etc. Resistivity, Easy Crosslinking Compatible Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

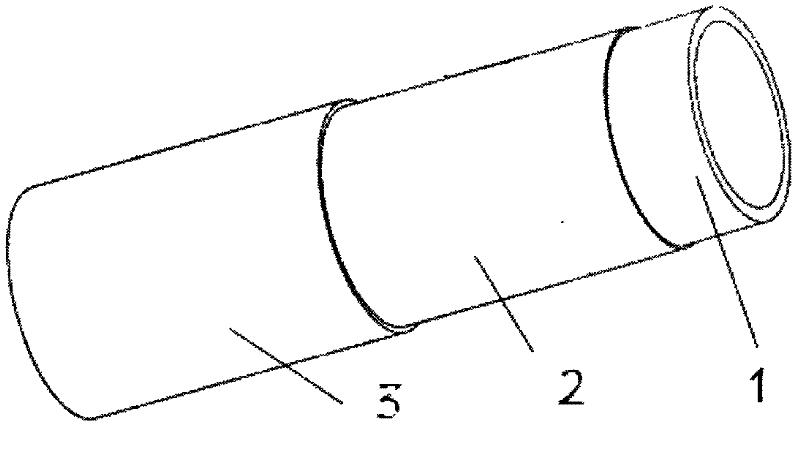

[0021] see figure 1 , The high-strength flame-retardant and antistatic pipe of the present invention is divided into three layers, the outer layer of plastic 3 , the bonding layer and the inner layer of plastic 1 . The bonding layer 2 is located between the outer plastic 3 and the inner plastic 1 .

[0022] Wherein the inner layer comprises the following components: 800 parts by weight of high-density polyethylene, 15 parts by weight of glass fiber, 2 parts by weight of wollastonite, 6 parts by weight of EPDM rubber, and 9 parts by weight of nitrile Glue, the styrene-butadiene-styrene terpolymer copolymer of 6 parts by weight, the carbon nanotube of 13 parts by weight, the polypropylene graft maleic anhydride of 30 parts by weight, the decabromobiphenyl of 25 parts by weight Ethane, the conductive carbon black of 19 parts by weight; The outer layer comprises the component of following ratio: the medium density polyethylene of 500 parts by weight, the decabromodiphenylethane o...

Embodiment 3

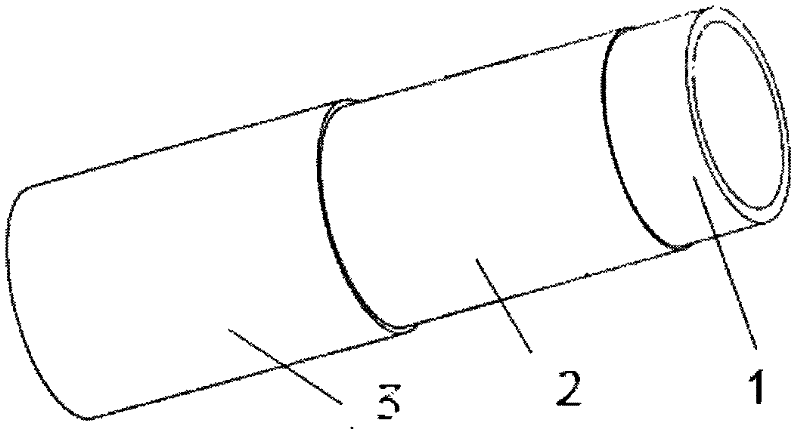

[0024] see figure 1 , The high-strength flame-retardant and antistatic pipe of the present invention is divided into three layers, the outer layer of plastic 3 , the bonding layer and the inner layer of plastic 1 . The bonding layer 2 is located between the outer plastic 3 and the inner plastic 1 .

[0025] Wherein the inner layer comprises components in the following proportions: 650 parts by weight of high-density polyethylene, 12 parts by weight of glass fiber, 2 parts by weight of wollastonite, 4 parts by weight of EPDM rubber, and 7 parts by weight of nitrile Glue, 5 parts by weight of styrene-butadiene-styrene terpolymer copolymer, 10 parts by weight of carbon nanotubes, 19 parts by weight of polypropylene grafted maleic anhydride, 19 parts by weight of decabromodiphenyl Ethane, the conductive carbon black of 16 parts by weight; The outer layer comprises the component of following ratio: the medium density polyethylene of 430 parts by weight, the decabromodiphenylethane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com