Antistatic antibacterial PC (polycarbonate)/ABS (acrylonitrile-butadiene-styrene copolymer) composite material

A composite material and antistatic technology, which is applied in the field of antistatic and antibacterial PC/ABS composite materials to achieve excellent antistatic properties, expand the scope of application, and reduce the density of combustion smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

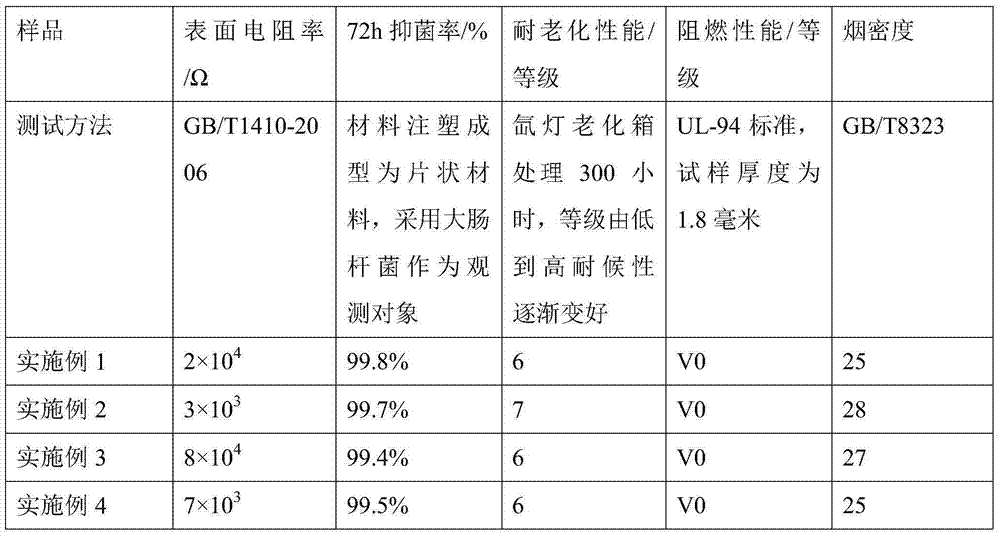

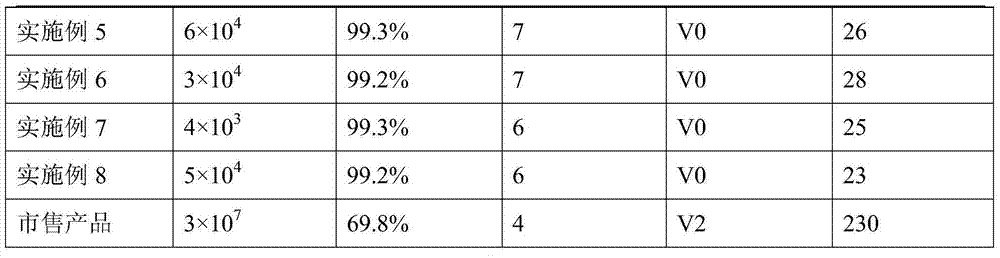

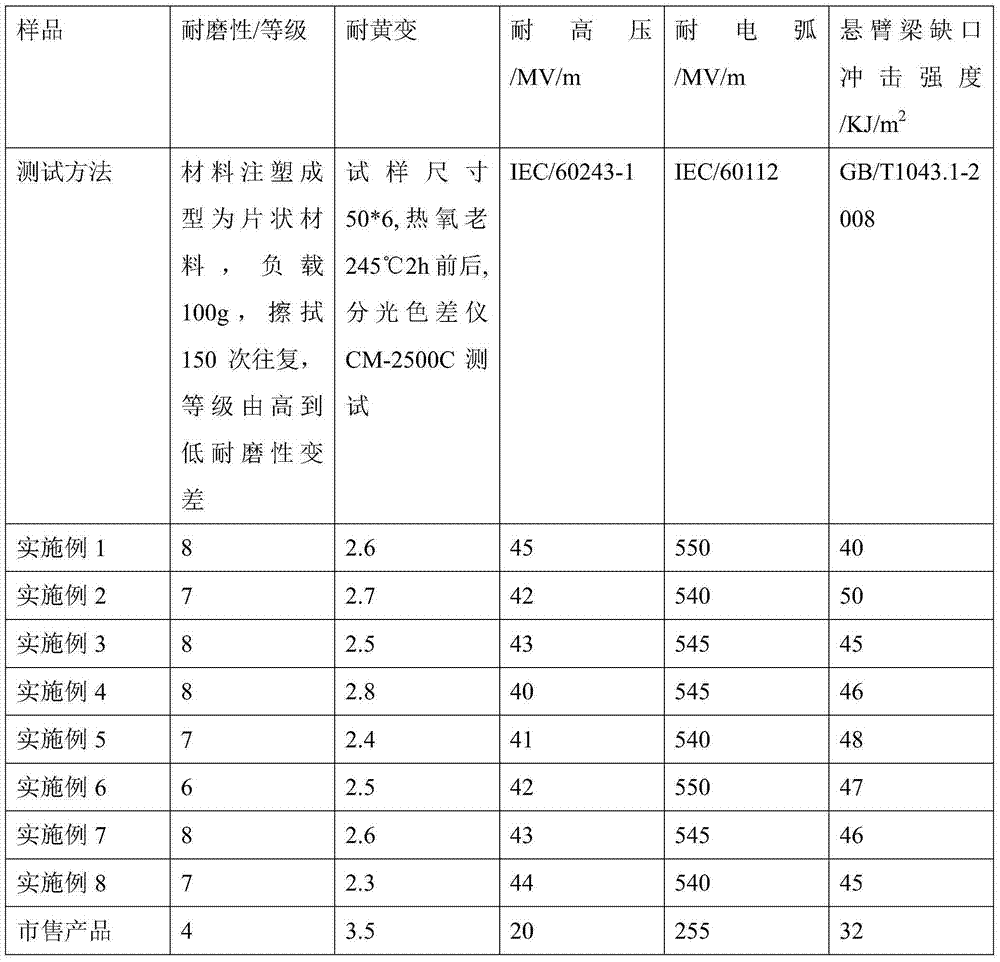

Examples

Embodiment 1

[0031] An antistatic and antibacterial PC / ABS composite material is composed of the following components in parts by weight: polycarbonate 63-93kg, ABS 57-65kg, melamine 33-47kg, nano antibacterial agent 29-44kg, 4,4'- Thiobis(6-tert-butyl-3-methylphenol) 41~47kg, sodium polystyrene sulfonate 24~32kg, polystyrene grafted methyl methacrylate copolymer 24~32kg, polyethylene wax 22kg ~26kg, methyl methacrylate-butadiene-styrene terpolymer 19~23kg, sodium metaborate 15~20kg, ultra-high molecular weight polyethylene 10~16kg, 2,4- 10-16 kg of the mixture of dihydroxybenzophenone and titanium dioxide and 17-24 kg of anti-wear agent.

[0032] After weighing the above-mentioned raw materials according to the quantity, each component is mixed to obtain a mixed material, and the above-mentioned mixed material is melted and extruded under the environment, and granulated to obtain the product. The temperature of each zone in the extruder is: zone 1 230°C, zone 2 245°C, zone 3 260°C, zone ...

Embodiment 2

[0034] An antistatic and antibacterial PC / ABS composite material is calculated by weight in kilograms and consists of the following components: polycarbonate 63-93kg, ABS 57-65kg, melamine 33-47kg, nano-antibacterial agent 29-44kg, 4,4'- Thiobis(6-tert-butyl-3-methylphenol) 41~47kg, sodium polystyrene sulfonate 24~32kg, polypropylene grafted acrylic acid copolymer 24~32kg, polyethylene wax 22~26kg, methyl 19-23kg of methyl acrylate-butadiene-styrene terpolymer, 15-20kg of sodium metaborate, 10-16kg of ultra-high molecular weight polyethylene, and 2,4-dihydroxybenzidine with a mass ratio of 3:2 The mixture of ketone and titanium dioxide is 10-16kg and the anti-wear agent is 17-24kg.

[0035] After weighing the above-mentioned raw materials according to the quantity, each component is mixed to obtain a mixed material, and the above-mentioned mixed material is melt-extruded and granulated to obtain the product. The temperature of each zone in the extruder is: zone 1 230°C, zone ...

Embodiment 3

[0037] An antistatic and antibacterial PC / ABS composite material is calculated by weight in kg, and consists of the following components: polycarbonate 79kg, ABS 59kg, bromostyrene 39kg, nano antibacterial agent 41kg, 4,4'-thiobis(6 -tert-butyl-3-methylphenol) 46kg, sodium polystyrene sulfonate 29kg, mass ratio are 1: 1 polystyrene graft methyl methacrylate copolymer and polypropylene graft acrylic acid copolymer 31kg, 25kg of polyethylene wax, 22kg of methyl methacrylate-butadiene-styrene terpolymer, 18kg of nano-organic montmorillonite, 13kg of ultra-high molecular weight polyethylene, and 2,4-dihydroxyl with a mass ratio of 3:2 14kg of mixture of benzophenone and titanium dioxide and 20kg of anti-wear agent.

[0038] After weighing the above-mentioned raw materials according to the quantity, each component is mixed to obtain a mixed material, and the above-mentioned mixed material is melt-extruded and granulated to obtain the product. The temperature of each zone in the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com