Stepped flame retardant plastic and preparation method thereof

A flame-retardant plastic and stepped technology, which is applied in the field of stepped flame-retardant plastics and their preparation, can solve the problems of non-halogen-based flame-retardant materials, such as dispersibility, poor fluidity, and inability to provide multi-stage flame-retardant effects, so as to improve mechanical properties. Strength, improved compatibility, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

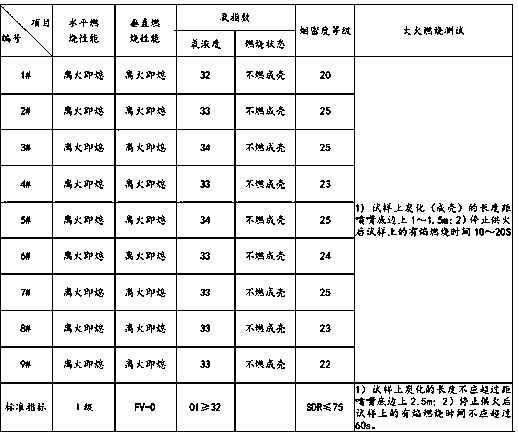

Examples

Embodiment 1

[0084] A stepped flame-retardant plastic, the plastic base material is PVC, and includes the following components in parts by weight:

[0085] PVC 800 parts;

[0086] 30 parts of inorganic flame retardant powder;

[0087]3 parts of zinc borate;

[0088] Silica powder 2 parts;

[0089] Al(OH) 3 1 copy;

[0090] 1 part calcium carbonate;

[0091] 0.3 parts of polymer dispersant;

[0092] Auxiliary 0.3 part.

[0093] Wherein, the particle size of the silicon micropowder is 0.1-0.3 mm, and the silicon micropowder with a particle size of 0.1 μm is not less than 80%. The polymer dispersant is a liquid carboxy-terminated nitrile rubber modified epoxy resin. Described auxiliary agent is lubricant, and described lubricant is ethylene bis stearic acid amide. The inorganic flame retardant powder is prepared from an inorganic silicon-aluminum shell-forming material, and the inorganic silicon-aluminum shell-forming material includes the following components in parts by weight:

...

Embodiment 2

[0111] A stepped flame-retardant plastic, the plastic base material is PVC, and includes the following components in parts by weight:

[0112] 1200 copies of PVC;

[0113] 120 parts of inorganic flame retardant powder;

[0114] 8 parts of zinc borate;

[0115] 5 parts of silica powder;

[0116] Mg(OH) 2 2 copies;

[0117] 2 parts calcium carbonate;

[0118] 1.2 parts of polymer dispersant;

[0119] Auxiliary 2 parts.

[0120] Wherein, the particle size of the silicon micropowder is 0.1-0.3 μm, and the silicon micropowder with a particle size of 0.1 μm is not less than 80%. Described macromolecule dispersant is liquid terminal hydroxyl nitrile rubber modified epoxy resin, and described auxiliary agent comprises lubricant and thermal stabilizer, and described lubricant is 1 part of pentaerythritol stearate, and described thermal stabilizer It is a compound low-lead heat stabilizer of 1 part. The inorganic flame retardant powder is prepared from an inorganic silicon-alu...

Embodiment 3

[0135] A preferred step-type flame-retardant plastic, the plastic base material is PVC resin, including the following components in parts by weight:

[0136] PVC 1000 copies;

[0137] 100 parts of inorganic flame retardant powder;

[0138] 5 parts of zinc borate;

[0139] 3 parts of silica powder;

[0140] Smoke suppressant 1.57 parts;

[0141] 0.5 part of polymer dispersant;

[0142] 1.5 parts of calcium carbonate;

[0143] Auxiliary 0.5 parts.

[0144] Wherein, the particle size of the silicon micropowder is 0.1-0.3 μm, and the silicon micropowder with a particle size of 0.1 μm is not less than 80%. Described smoke suppressant is the Al(OH) of 0.57 parts 3 and 1.0 parts of Mg(OH) 2 , the polymer dispersant is silicone modified epoxy resin. The auxiliary agent includes 0.3 part of lubricant, 0.1 part of plasticizer and 0.1 part of heat stabilizer. The lubricant is ethylene bis stearic acid amide, the plasticizer is a phthalate compound, and the heat stabilizer is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com