Preparation method of POSS-DOPO-triazine derivative flame retardant with self-assembled enhancement effect and application thereof

A triazine derivative and enhancement technology, applied in the field of flame retardants, can solve the problems of reducing the mechanical properties of the matrix, large additions, poor compatibility, etc., and achieve increased stability, increased heat insulation, and flame retardant good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

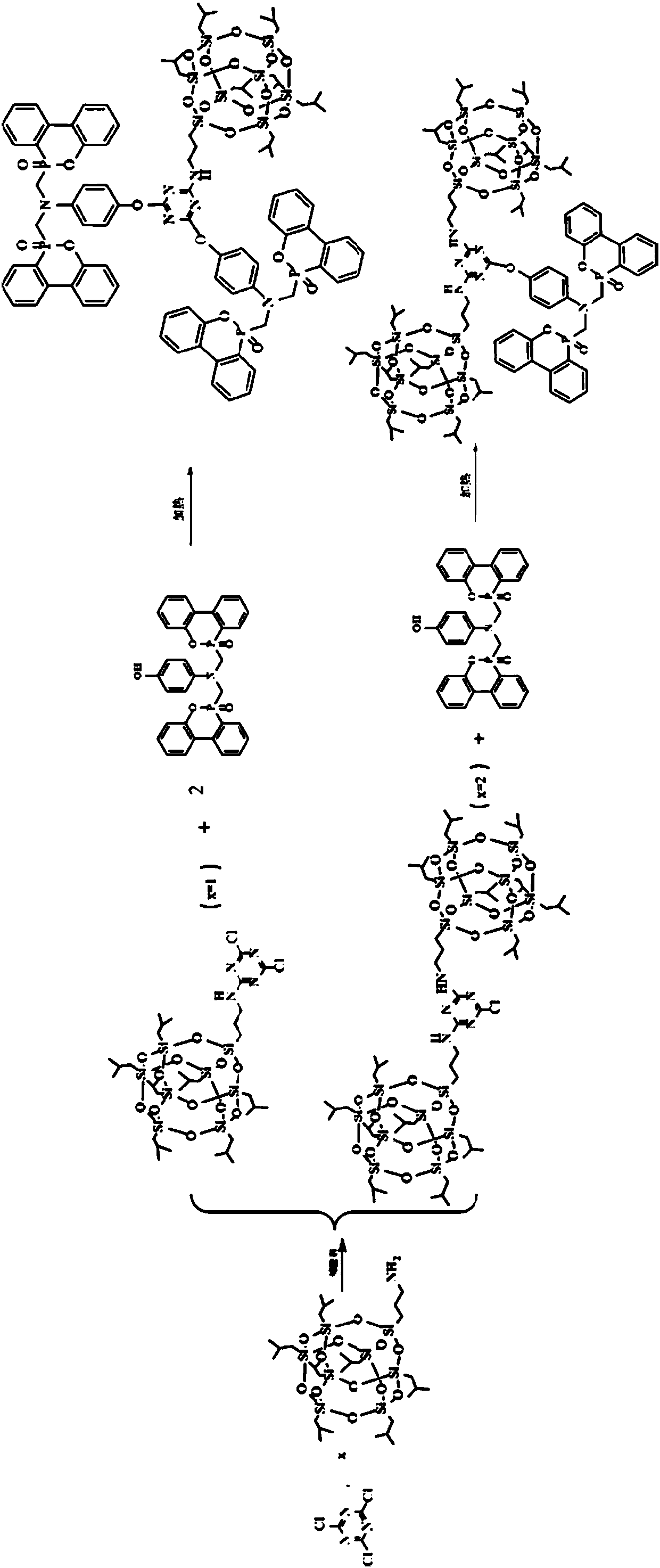

Method used

Image

Examples

Embodiment 1

[0040] (1) Synthesis of intermediate products

[0041] Add 1.84g (0.01mol) of cyanuric chloride and 50mL of tetrahydrofuran into a 250mL three-necked round-bottomed flask, then add 4.372g (0.005mol) of POSS-NH 2 Dissolve in 50mL of tetrahydrofuran, dissolve and stir at -5~0°C respectively to obtain the first solution and the second solution, add the second solution dropwise to the first solution, stir at low temperature, slowly rise to room temperature, and add the second solution at the same time An acid-binding agent 10% NaHCO 3 solution, keep the pH value at neutral, and react for 6 hours. After the reaction, the solvent is concentrated by rotary evaporation, washed with distilled water to remove the first acid-binding agent salts, and further precipitated with acetonitrile to obtain an intermediate product with a yield of about 83%. (2) Preparation of POSS-DOPO-triazine derivative flame retardant

[0042]The dioxane of 100mL and the dimethyl sulfoxide of 100mL were mixed...

Embodiment 2

[0047] (1) Synthesis of intermediate products

[0048] Add 1.84g (0.01mol) of cyanuric chloride and 50mL of tetrahydrofuran into a 250mL three-necked round-bottomed flask, then add 4.372g (0.005mol) of POSS-NH 2 Dissolve in 50mL of tetrahydrofuran, dissolve and stir at -5 ~ 0°C respectively to obtain the first solution and the second solution, add the second solution dropwise to the first solution, stir at low temperature, slowly rise to room temperature, and add First Acid Binder 10% NaHCO 3 Solution, keep the pH value as neutral, and react for 6h. After the reaction, the solvent was concentrated by rotary evaporation, the first acid-binding agent salt was removed by washing with distilled water, and the intermediate product was obtained by further precipitation with acetonitrile, and the yield was about 83%.

[0049] (2) Preparation of POSS-DOPO-triazine derivative flame retardant

[0050] The dioxane of 100mL and the dimethyl sulfoxide of 100mL were mixed to obtain the s...

Embodiment 3

[0055] (1) Synthesis of intermediate products

[0056] Add 1.84g (0.01mol) of cyanuric chloride and 50mL of tetrahydrofuran into a 250mL three-necked round-bottomed flask, then add 4.372g (0.005mol) of POSS-NH 2 Dissolve in 50mL of tetrahydrofuran, dissolve and stir at -5 ~ 0°C respectively to obtain the first solution and the second solution, add the second solution dropwise to the first solution, stir at low temperature, slowly rise to room temperature, and add First Acid Binder 10% NaHCO 3 Solution, keep the pH value as neutral, and react for 6h. After the reaction, the solvent was concentrated by rotary evaporation, the first acid-binding agent salt was removed by washing with distilled water, and the intermediate product was obtained by further precipitation with acetonitrile, and the yield was about 83%.

[0057] (2) Preparation of POSS-DOPO-triazine derivative flame retardant

[0058] The dioxane of 100mL and the dimethyl sulfoxide of 100mL were mixed to obtain the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com