Preparation method of flame-retardant modified polyvinyl acetate used for expanded polystyrene beads

A technology of polyvinyl acetate and expanded polystyrene, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of low flame retardant efficiency and achieve flame retardant High efficiency, mild reaction conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

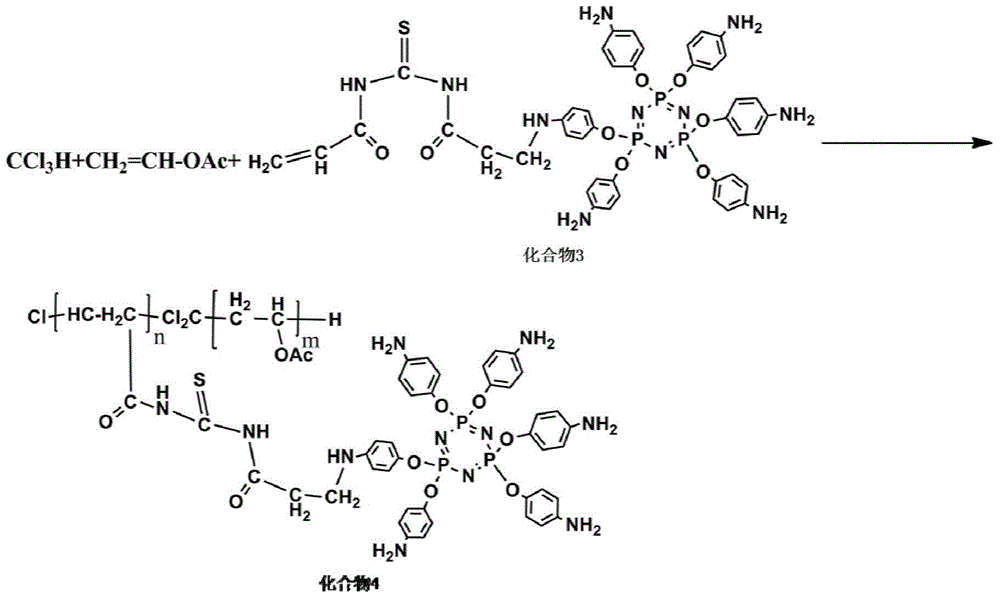

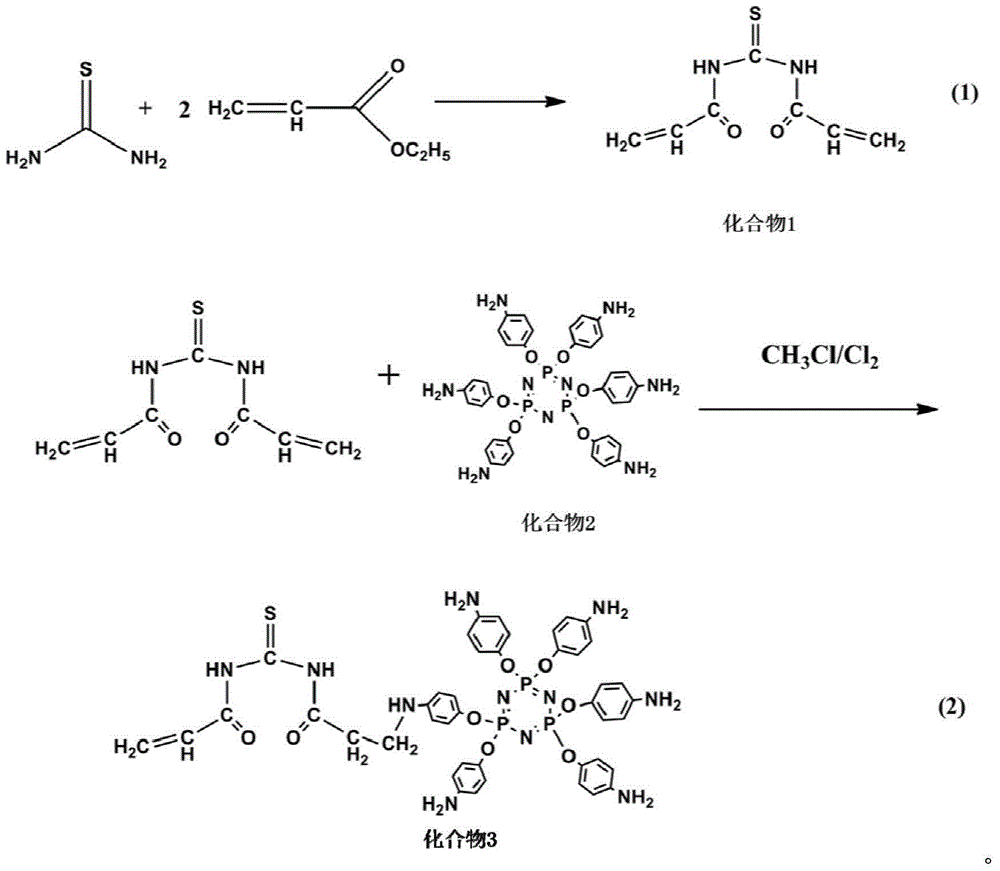

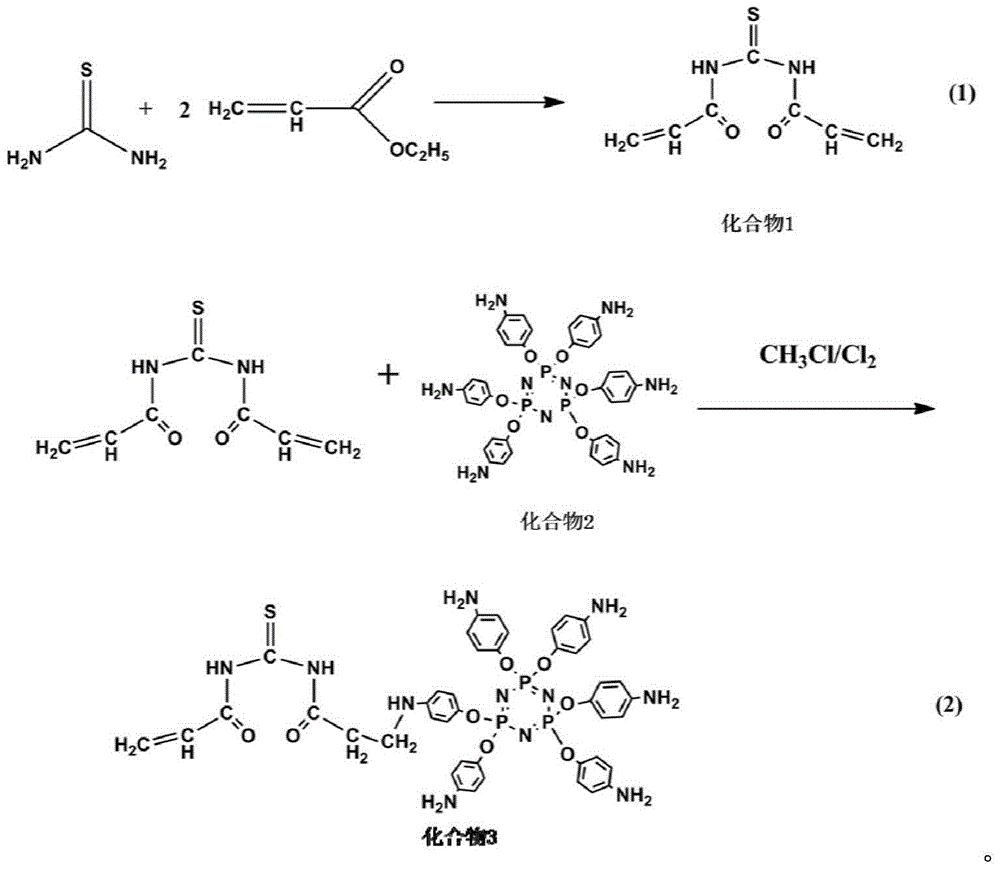

[0025] Add 7.6g of thiourea into the reaction flask, then add 20g of ethyl acrylate, then add 2g of anhydrous formic acid while raising the temperature to 50°C, and react for 4.5h; add 60g of hexaaminophenoxycyclotriphosphazene, in a Keep the reaction at 45°C for 1h in the methyl chloride environment; finally add 14g of vinyl acetate and 70g of chloroform, add the catalyst thionyl chloride, and react in the polar solvent toluene at 80°C for 10h, after the reaction is completed, cool to room temperature and discharge to obtain 1 - Thiourea Ethyl Acrylate - Hexaaminophenoxycyclotriphosphazene Polyvinyl Acetate.

Embodiment 2

[0027] Add 7.6g of thiourea into the reaction flask, then add 20g of ethyl acrylate, then add 1.5g of concentrated hydrochloric acid while raising the temperature to 40°C, and react for 5.5h; add 80g of hexaaminophenoxycyclotriphosphazene, Keep the reaction at 50°C in the environment for 0.5h; finally add 10g of vinyl acetate, 70g of chloroform, add the catalyst carbon tetrachloride, react in the polar solvent xylene at 60°C for 20h, cool to room temperature after the reaction, and discharge to obtain 1 - Thiourea Ethyl Acrylate - Hexaaminophenoxycyclotriphosphazene Polyvinyl Acetate.

Embodiment 3

[0029] Add 7.6g of thiourea into the reaction flask, then add 20g of ethyl acrylate, then add 1g of concentrated sulfuric acid while raising the temperature to 45°C, and react for 5h; add 80g of hexaaminophenoxycyclotriphosphazene, Keep the reaction at 40°C for 1.5h in the environment; finally add 18g of vinyl acetate, 70g of chloroform, add the catalyst triphenylphosphine, react in the polar solvent tetrahydrofuran at 70°C for 15h, cool to room temperature and discharge after the reaction, and obtain 1- Thiourea ethyl acrylate-hexaaminophenoxycyclotriphosphazene polyvinyl acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com