High extended secondary cold-rolled plate and production method thereof

A technology of secondary cold rolling and final rolling temperature, applied in the field of secondary cold rolled sheet, can solve the problems of insufficient ductility of secondary cold rolled sheet, large deformation rate of secondary cold rolling, low material elongation, etc. The effect of ductility, good processability and low production cost

Active Publication Date: 2013-04-03

BAOSHAN IRON & STEEL CO LTD

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There is no problem if the secondary cold-rolled DR material is used as a three-piece can, but if it is used for some DRD food cans or easy-open lids, cracking is likely to occur due to the lack of ductility of the secondary cold-rolled sheet

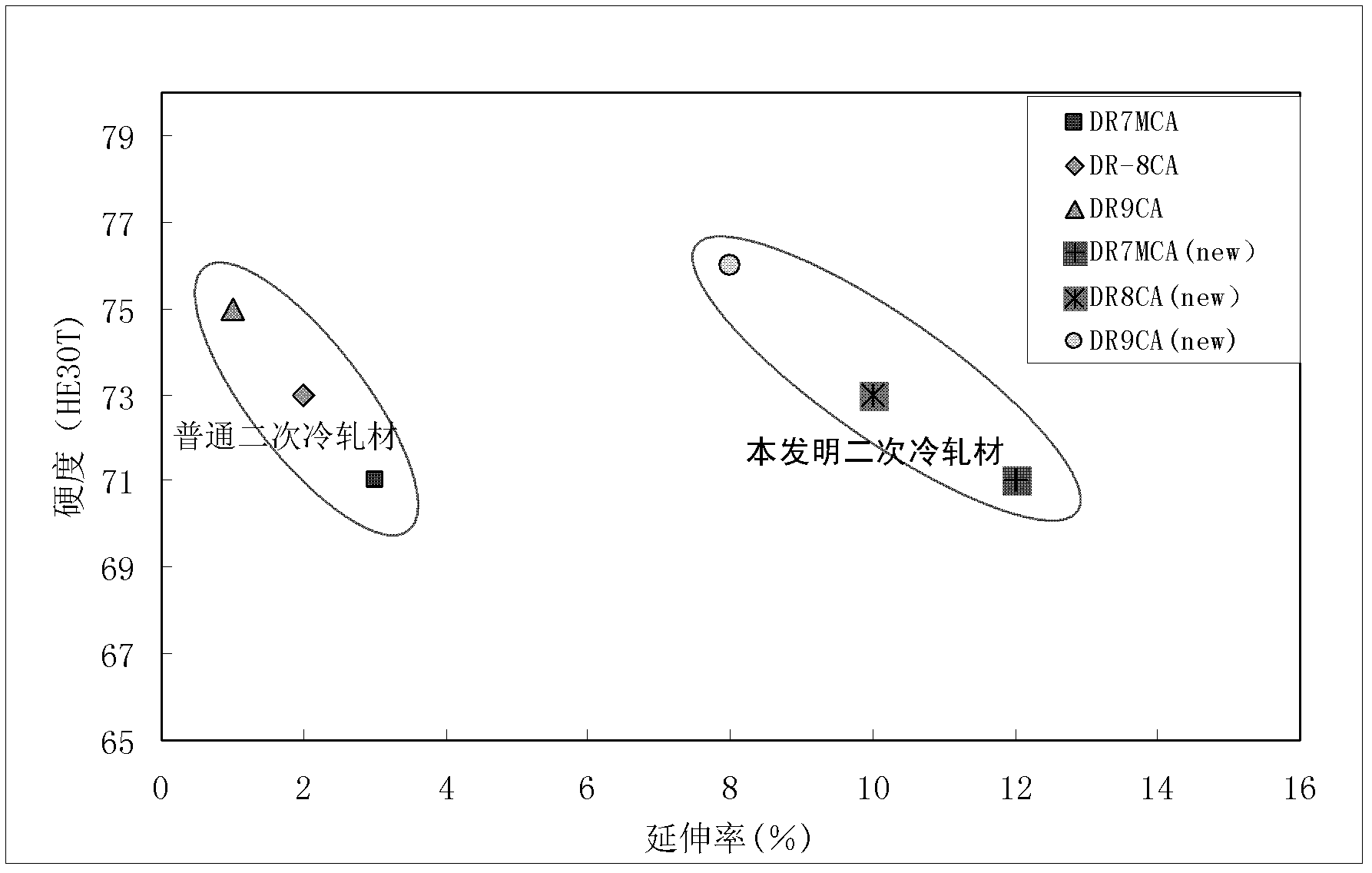

Some secondary cold-rolled tin-plated product manufacturing technologies can produce high-hardness secondary cold-rolled products, but because the secondary cold-rolled deformation rate is generally relatively large, the elongation of the produced materials is also relatively low, generally between 0- 4%, especially when the secondary cold rolling deformation rate is greater than 30%, the elongation of the material is basically close to 0%, such as figure 1 The ordinary DR7MCA, DR8CA, and DR9CA shown (see GB / T 2520-2008, JIS G3303:2008, ASTMA623M-08 respectively) meet the hardness required by the product standard, and the elongation of the material is basically less than 3%.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

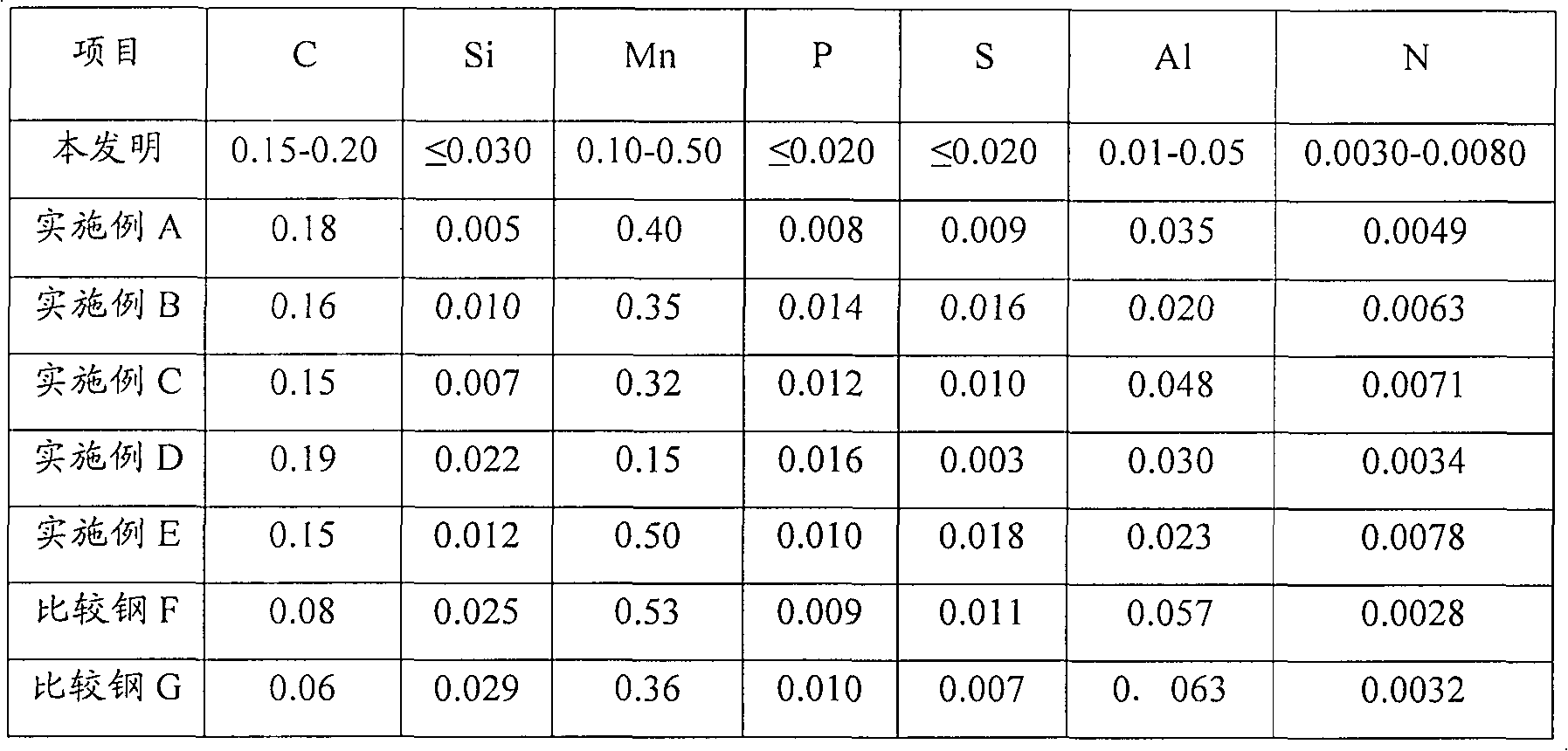

[0038] The chemical compositions of the four examples (A-E) and two comparative examples (F, G) of the present invention are shown in Table 1 below.

[0039] Table 1 wt%

[0040]

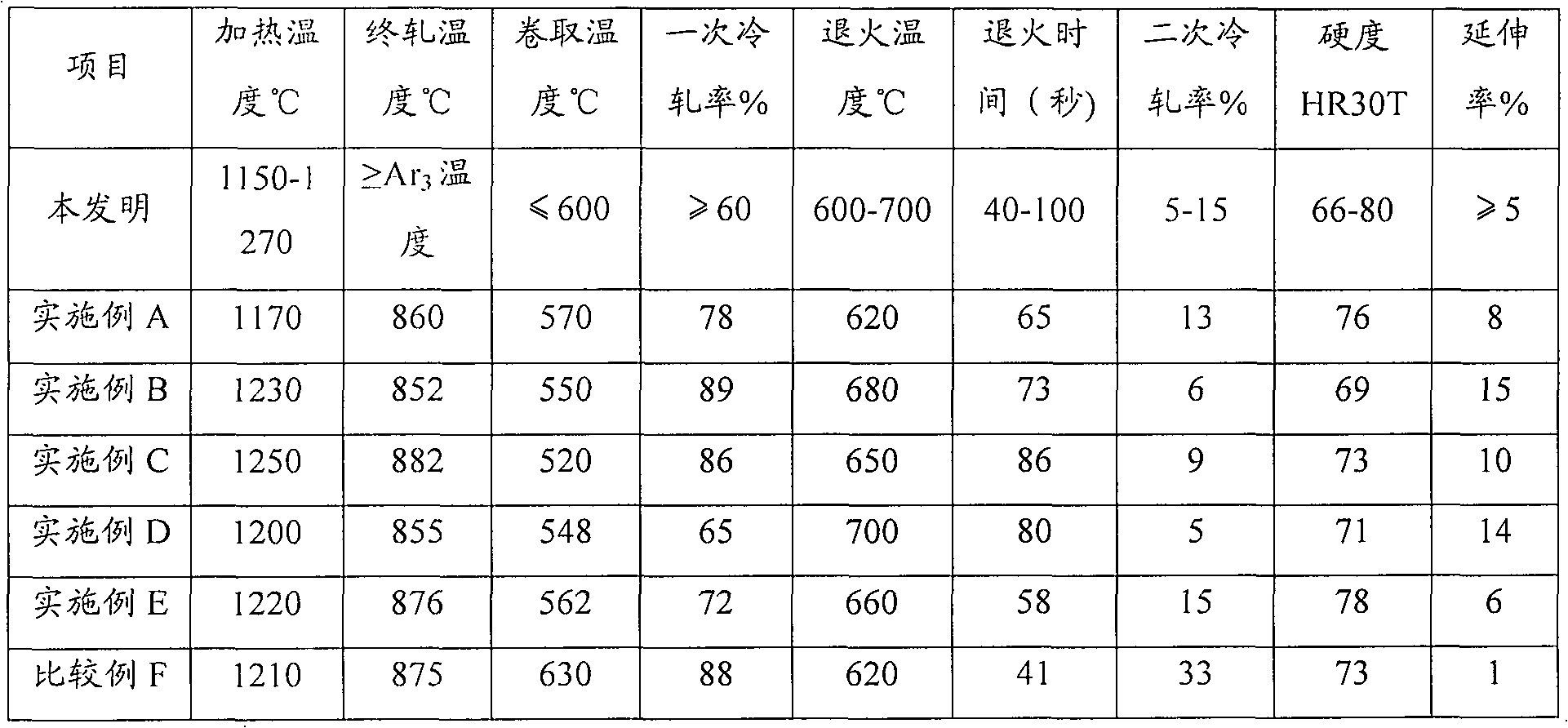

[0041] See Table 2 for the specific processes and properties of hot rolling and cold rolling of the four examples (A-E) and two comparative examples (F, G) of the present invention.

[0042] Table 2

[0043]

[0044]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a high extended cold-rolled plate, which comprises the following chemical components in percentage by weight: 0.15-0.20% of C, less than or equal to 0.030% of Si, 0.10-0.50% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.01-0.05% of Al, 0.0030-0.0080% of N, and the balance of iron and inevitable impurity. The production method comprises the following steps: carrying out iron pretreatment, converter melting, refining after the furnace, hot rolling, scouring, cold rolling, continuous annealing, secondary cold rolling, finishing to obtain the finished product roll, wherein in the process of the hot rolling, the controlled heating temperature is 1150-1270 DEG C, the finish rolling temperature is more than Ar3, the coiling temperature is less than or equal to 600 DEG C, the cold rolling deflection is more than or equal to 60%, the continuous annealing temperature is 600-700 DEG C, the annealing time is 40-100 seconds, the secondary cold rolling ratio is 5-15%, the hardness of the obtained secondary cold-rolled plate is HR30T66-80, and the tensile extension is more than or equal to 5%.

Description

technical field [0001] The invention relates to a secondary cold-rolled sheet, in particular to a high-elongation secondary cold-rolled sheet and a manufacturing method thereof. The cold-rolled sheet is used for making steel products with high elongation requirements such as easy-open lids and stamped cans. Background technique [0002] Tin plate and chrome plate are widely used in can bodies and lids in the food packaging industry. The secondary cold-rolled tin-plated (chrome-plated) product developed in recent years has become the first choice for steel tank manufacturers to reduce costs and ensure quality because of its high strength, extremely thin thickness, and high elongation. Due to the complicated production of three-piece cans, stamped cans DRD and cupped cans DI are used instead, and they are mainly used in the field of food cans and beverage cans. There is no problem if the secondary cold-rolled DR material is used as a three-piece can, but if it is used for som...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/04C21D8/02

Inventor 班必俊

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com