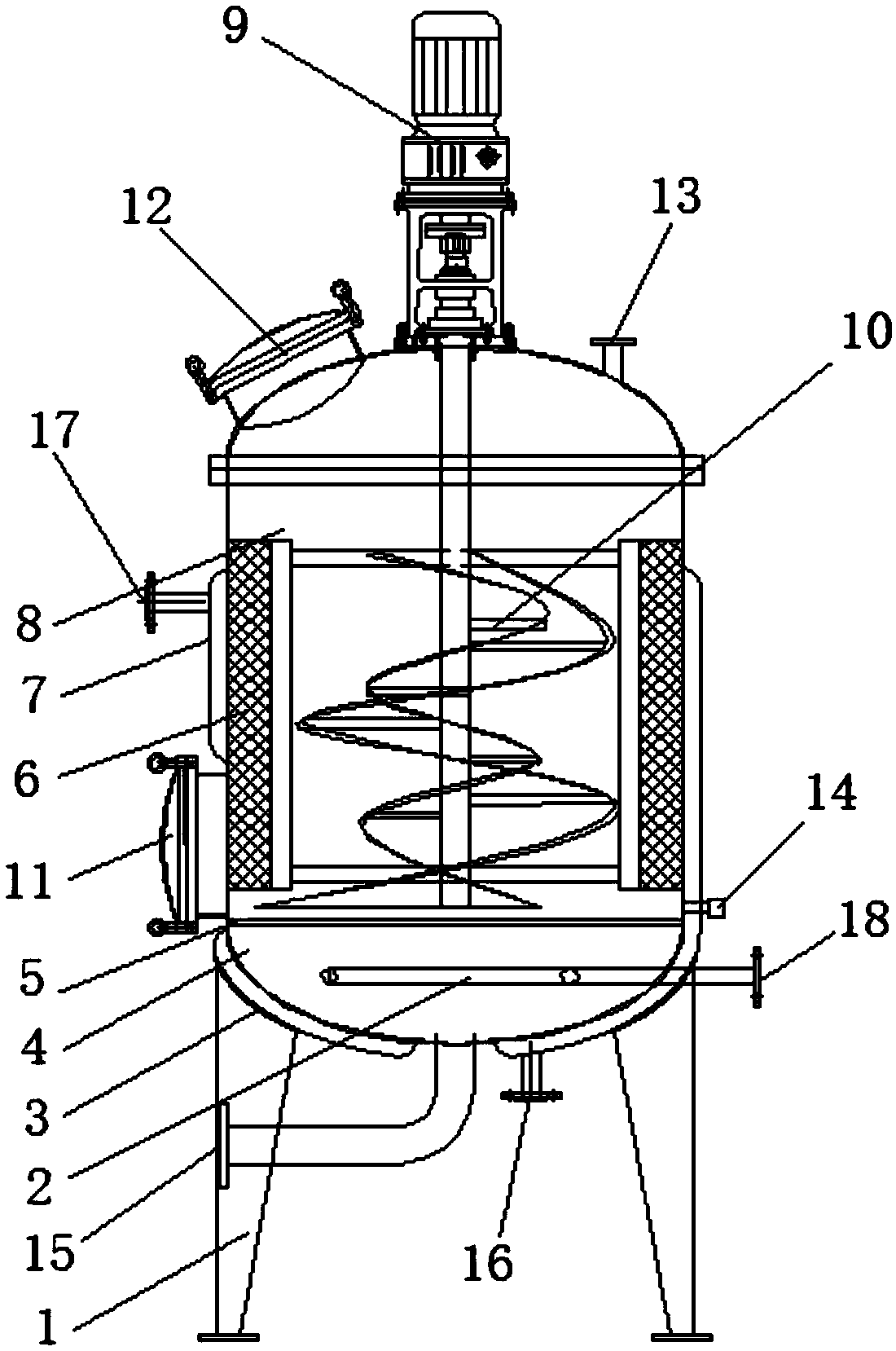

Differential double-spiral stirring type integrated solid fermenting device

A solid fermentation device and double-screw stirring technology are applied in the field of differential double-screw agitation integrated solid fermentation devices, which can solve the problems of easy pollution, difficult heat dissipation, unbalanced growth, etc., and achieve the effects of less pollution and less pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

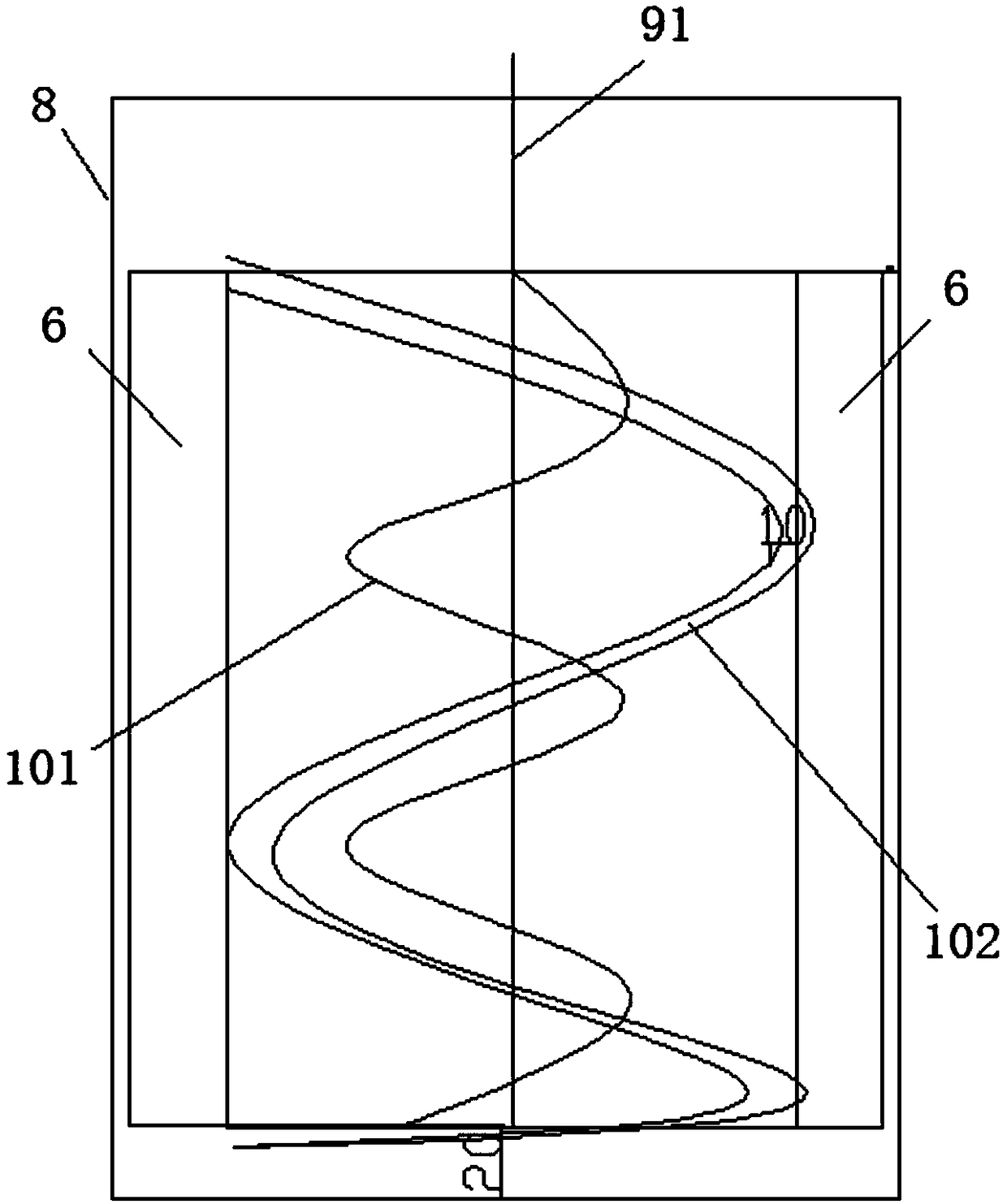

Method used

Image

Examples

Embodiment 1

[0026] Take wheat bran and water according to the ratio of 1:0.5, add them into the feeding port, start stirring the mixed materials to form loose materials.

[0027] The jacket is fed with steam sterilized materials, and when the temperature reaches 95°C, the stirring is stopped, and the sterilization is continued through direct steam into the tank, and the temperature is kept at 121°C for 45 minutes.

[0028] Pass in sterile air to cool down, and pass in jacket water to cool down. When the temperature in the tank drops to 100°C, start stirring to quickly mix and dissipate heat.

[0029] When the temperature of the material reaches 34°C, the seeds can be added to the sterilized medium through the inoculation port, and the seed liquid can be mixed by reverse stirring.

[0030] Due to the moisturizing effect of the solid fermentation tank, moist air is introduced through the bottom, and evenly dispersed into the medium through the filter mesh bottom plate at the bottom to accel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com