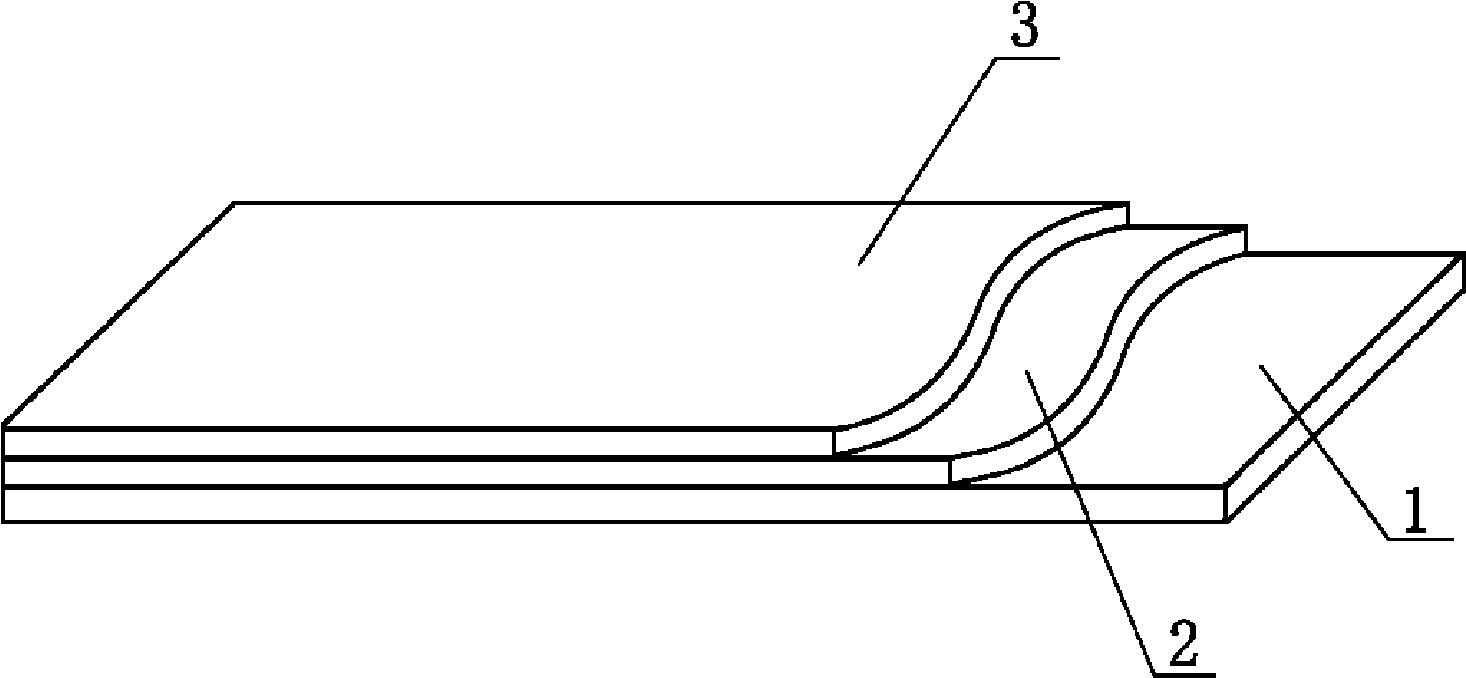

Self-adhering rubber water-proof coiled material and method for preparing same

A self-adhesive rubber and waterproof membrane technology, applied in water conservancy projects, building insulation materials, building components and other directions, can solve the problems of water channeling and leakage, the rubber waterproof membrane is not tightly combined with the base layer, etc., to save construction time, avoid Pollution of the environment and hidden dangers of fire protection, the effect of high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, the above-mentioned self-adhesive rubber waterproof layer is formed by mixing the following materials in proportions by weight:

[0034] 60 parts of EPDM rubber;

[0035] 12 parts of butyl rubber;

[0036] Neoprene 5 parts;

[0037] 55 parts of carbon black;

[0038] Light calcium 50 parts;

[0039] 2 parts Coumarron;

[0040] 15 parts naphthenic oil;

[0042] 1 part stearic acid;

[0043] 1 part sulfur;

[0044] 0.5 parts of ethylene thiourea;

[0045] 0.5 parts of tetramethylthiuram disulfide;

[0046] Dithiol benzothiazole 0.2 parts.

Embodiment 2

[0047] Embodiment 2, the above-mentioned self-adhesive rubber waterproof layer is formed by mixing the following materials in proportions by weight:

[0048] 64 parts of EPDM rubber;

[0049] 12 parts of butyl rubber;

[0050] Neoprene 10 parts;

[0051] 60 parts of carbon black;

[0052] 62 parts of light calcium;

[0053] Coumarron 4 parts;

[0054] 12 parts naphthenic oil;

[0056] 1 part stearic acid;

[0057] 0.5 parts of methyl phenyl disulfide;

[0058] 0.5 parts of ethylene thiourea;

[0059] Dibenzothiazole disulfide 1 part.

Embodiment 3

[0060] Embodiment 3, the above-mentioned self-adhesive rubber waterproof layer is formed by mixing the following materials in proportions by weight:

[0061] 70 parts of EPDM rubber;

[0062] 26 parts of butyl rubber;

[0063] Neoprene 20 parts;

[0064] 65 parts of carbon black;

[0065] Light calcium 70 parts;

[0066] Coumarone 6.5 parts;

[0067] 18 parts naphthenic oil;

[0068] 8 parts of zinc oxide;

[0069] 1.2 parts of stearic acid;

[0070] 1.2 parts of sulfur;

[0071] 0.7 parts of methyl phenyl disulfide;

[0072] 1 part of ethylene thiourea;

[0073] Tetramethylthiuram disulfide 0.5-1.5 parts;

[0074] 1 part of dibenzothiazole disulfide;

[0075] Dithiol benzothiazole 1 part.

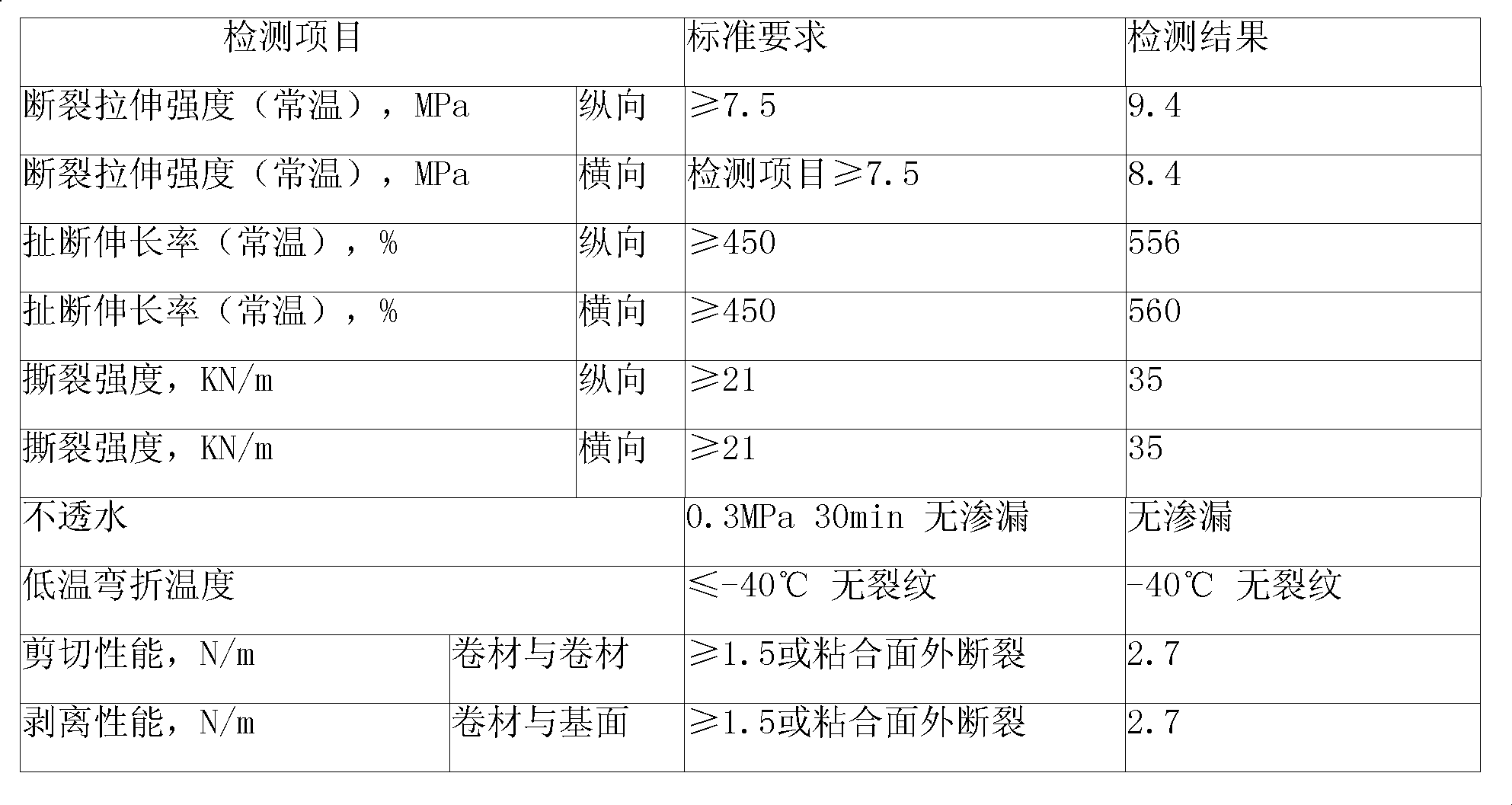

[0076] The detection test data of the embodiment of the present invention three are as follows:

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com