High-adhesion LED-UV piezoelectric spray printing ink and preparation method thereof

A high-adhesion, piezoelectric technology, used in inks, household appliances, applications, etc., can solve the description of expanded color gamut, the viscosity range is not applicable, and the application method and application of LED-UV inkjet printing ink are not mentioned. results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0344] 1. Preparation of pigment paste:

[0345] See Table 1 for the composition of sub-micron-sized Yellow, Magenta, Cyan, and Black colorants; see Table 2 for the composition of sub-micron-sized White White colorants.

[0346] Table 1 Composition of sub-micron size Yellow, Magenta, Cyan, Black pigment paste

[0347]

[0348] Table 2 Composition of sub-micron size White pigment paste

[0349]

[0350] Make color pastes of different colors according to the following production steps. Color paste production steps are as follows:

[0351] 1) Mix the pigment, polymerization inhibitor, reactive monomer solvent, and dispersant according to the formula in Table 1 and 2 to form a slurry, mix, and perform the pre-dispersion and wetting step for more than 8 hours;

[0352] 2) Put the slurry prepared in step 1) into a NETZSCH 10L grinder for high-speed grinding and dispersion. The grinding characteristics are: 300kg feeding amount, and the energy consumption per hour during gri...

preparation example

[0391] [Preparation example, embodiment and comparative example part]:

[0392] l Preparation example:

[0393] 1. Use a high-speed paint shaker to make color paste:

[0394]The pigments used are as follows: Magenta: C.I. Pigment Red 122; Blue: C.I.Pigment Blue 15:4; Yellow: C.I. Pigment Yellow 150; Black: C.I.Pigment Black 7; For white use toner: C.I. Pigment White 6.

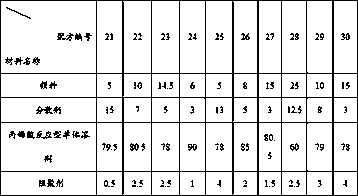

[0395] The dispersant formula 1-10 used is BYK9151, the formula 11-20 is PB822, and the formula 21-30 is BYK9152; the polymerization inhibitor formula 1-15 used is 4-methoxyphenol, and the formula 16-30 is Lang GENORAD* 16 of RAHN company; the acrylic acid reactive monomer solvent or oligomer used is isobornyl acrylate for formula 1-5, 11-15, 21-25, formula 6-10, 16-20 , 26-30 is benzyl acrylate.

[0396] Among them, the composition of sub-micron size yellow Yellow, magenta Magenta, cyan Cyan, and black black color paste is shown in Table 3; the composition of sub-micron size white White color paste is sho...

Embodiment 1

[0424] Ø Example 1: Prepare the ink according to formula 31; the pigment color paste used is formula 1, and the polyurethane-acrylic resin used is UA-4200.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com