Preparation method of high-solid-content low-viscosity acrylate emulsion for sealing gum

An acrylate, high solid content technology, used in chemical instruments and methods, adhesive types, ester copolymer adhesives, etc. , Unfavorable high-speed mixing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

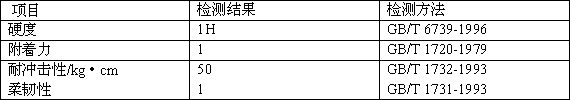

Examples

Embodiment 1

[0017] The present invention comprises the following steps:

[0018] 0.28kg N-methylolacrylamide, 0.043 kg NaHCO 3 Dissolve in 5.4 kg deionized water, after all dissolved, add 24.5 kg ethyl acrylate, 3.5 kg methyl methacrylate, 2.7 kg isooctyl acrylate, 0.8 kg acrylic acid, 3.5 kg butyl acrylate under nitrogen atmosphere at room temperature Stir well to obtain a mixture. Vacuumize the reactor and fill it with nitrogen three times, heat up to 80°C, add 2.3 kg of deionized aqueous solution in which 0.059 kg of potassium persulfate is dissolved, add the above mixed solution with a mass of about 16.2 kg into the reactor, and drop React at constant temperature for 20 minutes, add 3.2 kg of aqueous solution containing 0.06 kg of sodium lauryl sulfate and 0.01 kg of polyoxyethylene octylphenol ether (OP-21) to the remaining 24.2 kg of the above mixed solution to make a pre-emulsion, stir and emulsify After 0.5 h, the pre-emulsion and 2.7 kg of deionized aqueous solution containing ...

Embodiment 2

[0022] Embodiment 2: a kind of preparation method of high-solid-content low-viscosity acrylate emulsion for sealant comprises the following steps:

[0023] 0.21 kg N-methylolacrylamide, 0.043 kg NaHCO 3Dissolve in 5.4 kg deionized water, after all dissolved, add 24.5 kg ethyl acrylate, 3.5 kg methyl methacrylate, 2.7 kg isooctyl acrylate, 0.8 kg acrylic acid, 3.5 kg butyl acrylate under nitrogen atmosphere at room temperature Stir well to obtain a mixture. Vacuumize the reactor and fill it with nitrogen three times, raise the temperature to 80°C, add 1.8 kg of deionized aqueous solution dissolved with 0.059 kg of potassium persulfate, add the mixed solution with a mass of about 16.2 kg into the reactor dropwise, and keep the temperature constant After reacting for 20 minutes, add 1.8 kg of aqueous solution dissolved with 0.06 kg of sodium lauryl sulfate and 0.01 kg of polyoxyethylene octylphenol ether (OP-21) to the remaining 24.2 kg of the mixed solution to make a pre-emulsi...

Embodiment 3

[0025] A kind of preparation method of high-solid-content low-viscosity acrylate emulsion for sealant, comprises the following steps:

[0026] 0.11 kg N-methylolacrylamide, 0.043 kg NaHCO 3 Dissolve in 3.4 kg deionized water, after all dissolved, add 24.5 kg ethyl acrylate, 3.5 kg methyl methacrylate, 2.7 kg isooctyl acrylate, 0.8 kg acrylic acid, 3.5 kg butyl acrylate under nitrogen atmosphere at room temperature Stir well to obtain a mixture. Vacuumize the reactor and fill it with nitrogen three times, raise the temperature to 80°C, add 1.4 kg of deionized aqueous solution in which 0.059 kg of potassium persulfate is dissolved, add the mixed solution with a mass of about 15.3 kg into the reactor dropwise, and keep the temperature constant After reacting for 20 minutes, add 2.0 kg of an aqueous solution containing 0.09 kg of sodium lauryl sulfate and 0.02 kg of polyoxyethylene octylphenol ether (OP-21) to the remaining 23.1 kg of the mixed solution to make a pre-emulsion, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com