Highly-wear-resistant and antistatic type EPDM waterproof coil material and preparation method thereof

A technology of EPDM and waterproof membranes, which is applied to flat products, building insulation materials, and other household appliances. It can solve problems such as short service life, poor adhesive bonding effect, and poor antistatic ability, and achieve Improve the bonding effect, not easy to fall off with glue, strong antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

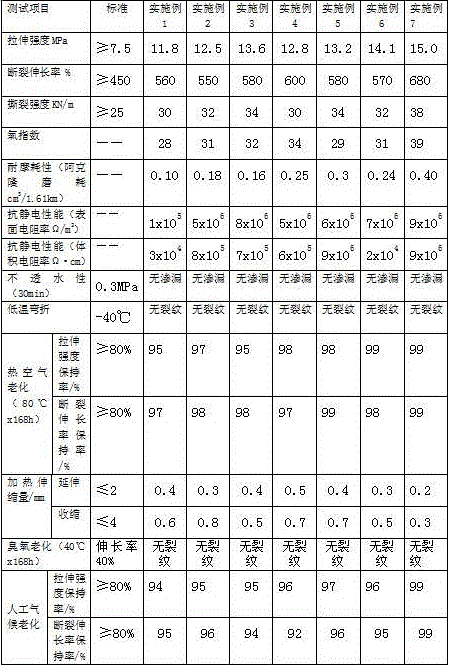

Examples

Embodiment 1

[0072] Example 1: Preparation method of high wear resistance and antistatic EPDM waterproof coiled material

[0073] A. Ingredients: accurately weigh out 70 parts of EPDM rubber in parts by weight; 20 parts of styrene butadiene rubber; 10 parts of butadiene rubber; 45 parts of naphthenic oil; 45 parts of carbon black N550; 25 parts of nano-silica; phenolic resin SP-1055 10 parts; Chemical silane coupling agent KH-550 5 parts; Anti-aging agent RD 0.5 parts; Acetylene carbon black 25 parts; Decabromodiphenyl ether 5 parts, Decabromodiphenyl ethane 10 parts; Nano zinc oxide 4.5 parts; 1 part of stearic acid; 1.5 parts of insoluble sulfur IS-60; 1 part of accelerator TMTD; 1.5 parts of accelerator DM; 1.5 parts of accelerator CZ, for use;

[0074] Among them: in step A:

[0075] The antioxidant RD is 2,2,4-trimethyl-1,2-dihydroquinoline polymer;

[0076] The accelerator TMTD is an accelerator tetramethylthiuram disulfide;

[0077] The accelerator DM is accelerator 2, 2'-dithiodibenzothiaz...

Embodiment 2

[0092] Example 2: Preparation method of high wear resistance and antistatic EPDM waterproof coiled material

[0093] A. Ingredients: accurately weigh 80 parts by weight of EPDM rubber; 20 parts of styrene butadiene rubber; 15 parts of butadiene rubber; 50 parts of naphthenic oil; 30 parts of carbon black N330; 20 parts of carbon black N550; 15 parts of silicon oxide; 20 parts of C5 / C9 petroleum resin; 5 parts of chemical silane coupling agent KH-560; 0.5 parts of anti-aging agent RD; 25 parts of acetylene carbon black; 5 parts of decabromodiphenyl ether, decabromodiphenyl ethane 10 parts; 4.5 parts of nanometer zinc oxide; 1 part of stearic acid; 1.5 parts of insoluble sulfur IS-80; 1 part of accelerator TMTD; 1.5 parts of accelerator DM; 1.5 parts of accelerator CZ, ready for use.

[0094] B. Internal mixing: the EPDM, styrene butadiene rubber, butadiene rubber, naphthenic oil, semi-reinforcing carbon black N330, carbon black N550, nano-silica, C5 / C9 weighed in step A Petroleum r...

Embodiment 3

[0098] Example 3: Preparation method of high wear-resistant and antistatic EPDM waterproof coiled material

[0099] A. Ingredients: accurately weigh 75 parts by weight of EPDM rubber; 22 parts of natural rubber; 18 parts of butadiene rubber; 50 parts of naphthenic oil; 30 parts of carbon black N234; 20 parts of carbon black N550; nano-level dioxide 15 parts of silicon; 10 parts of C5 / C9 petroleum resin; 8 parts of chemical aluminate coupling agent DL-411; 0.5 part of antioxidant RD; 20 parts of quaternary ammonium nitrate; 8 parts of decabromodiphenyl ether, decabromodiphenyl 13 parts of ethane; 5 parts of nanometer zinc oxide; 1 part of stearic acid; 1.0 part of insoluble sulfur; 0.5 part of accelerator TMTD; 1.2 parts of accelerator DM; 1.8 parts of accelerator PZ, ready to use.

[0100] B. Internal mixing: the EPDM, natural rubber, butadiene rubber, naphthenic oil, medium and super wear-resistant carbon black N234, carbon black N550, nano-scale silica, and C5 / C9 petroleum weighe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com