Low temperature resisting polymer modified emulsified asphalt waterproof coating

A technology for emulsified asphalt and waterproof coating, applied in the direction of asphalt coating, chloroprene homopolymer coating, coating, etc., can solve the problems of high environmental temperature requirements and large environmental temperature constraints, and achieve short drying time , No health hazard, fast film forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

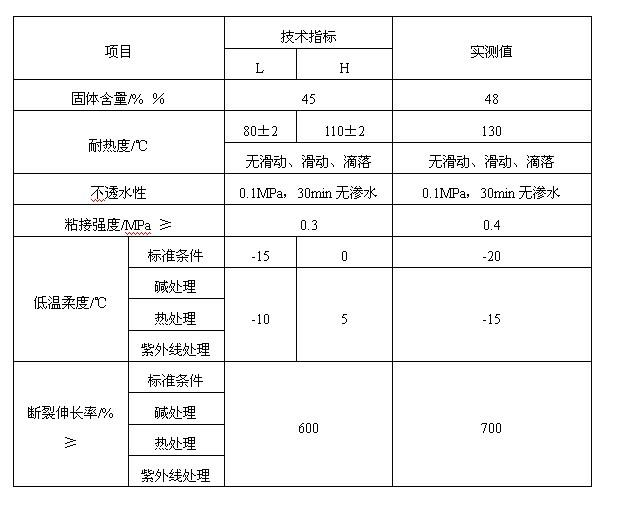

Embodiment 1

[0016] The components and parts by weight of the polymer modified emulsified asphalt waterproof coating are as follows:

[0017] Asphalt A 28 parts

[0018] Asphalt B 5 parts

[0019] 20.2 parts of polymer emulsion

[0020] Emulsifier 0.8 parts

[0021] 30 parts of water

[0022] Antifreeze 15.7 parts

[0023] Drier 0.2 parts

[0024] Thickener 0.1 part

[0025] Asphalt A is the 90# petroleum asphalt of Qinhuangdao PetroChina Fuel Asphalt Co., Ltd., the 90# petroleum asphalt of Taizhou Hailing District Haizhichun Petrochemical Co., Ltd., the 90# petroleum asphalt of Maoming Petrochemical or the 90# petroleum asphalt of Jiujiang Petrochemical.

[0026] Asphalt B is the 10# construction petroleum asphalt of Sinopec, the 10# construction petroleum asphalt of Maoming Petrochemical or the 10# construction petroleum asphalt of Qilu Petrochemical.

[0027] The polymer emulsion is CRL50LK cationic neoprene latex from Shanghai Jucheng Chemical Co., Ltd. or CRL50LK cationic neopr...

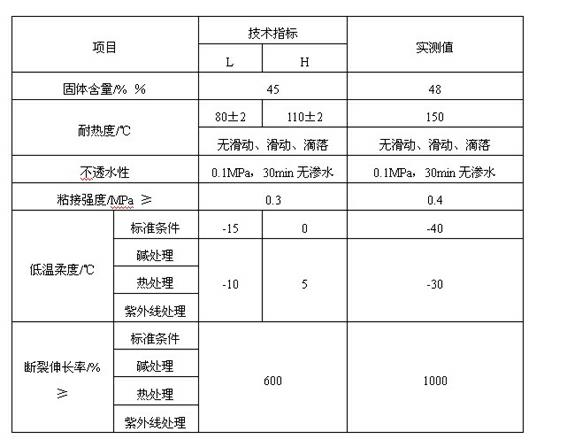

Embodiment 2

[0036] The components and parts by weight of the polymer modified emulsified asphalt waterproof coating are as follows:

[0037] Asphalt A 23 parts

[0038] Asphalt B 7 parts

[0039] Polymer emulsion 25 parts

[0040] Emulsifier 1.3 parts

[0041] 23 parts of water

[0042] Antifreeze 20.4 parts

[0043] Drier 0.2 parts

[0044] Thickener 0.1 part

[0045] Asphalt A is the 90# petroleum asphalt of Qinhuangdao PetroChina Fuel Asphalt Co., Ltd., the 90# petroleum asphalt of Taizhou Hailing District Haizhichun Petrochemical Co., Ltd. or the 90# petroleum asphalt of Maoming Petrochemical or the 90# petroleum asphalt of Jiujiang Petrochemical.

[0046] Asphalt B is the 10# construction petroleum asphalt of Sinopec or the 10# construction petroleum asphalt of Maoming Petrochemical or the 10# construction petroleum asphalt of Qilu Petrochemical.

[0047] The polymer emulsion is the isoprene latex IR-550 of Linshi New Chemical Materials Co., Ltd. or the isoprene latex of Wuhan...

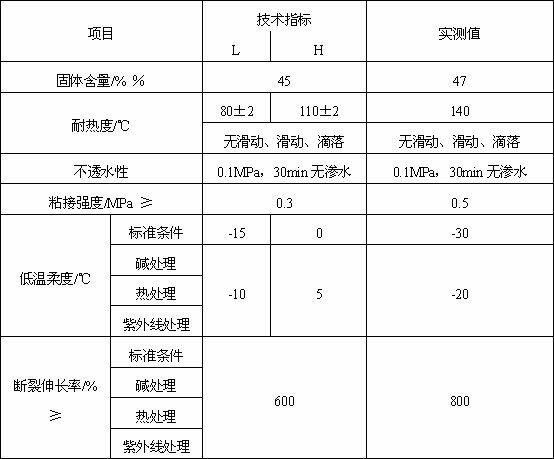

Embodiment 3

[0056] The components and parts by weight of the polymer modified emulsified asphalt waterproof coating are as follows:

[0057] Asphalt A 25 parts

[0058] Asphalt B 5 parts

[0059] Polymer emulsion 23 parts

[0060] 1 part emulsifier

[0061] 30 parts of water

[0062] Antifreeze 15 parts

[0063] Drier 0.5 parts

[0064] Thickener 0.5 parts

[0065]Asphalt A is the 90# petroleum asphalt of Qinhuangdao PetroChina Fuel Asphalt Co., Ltd., the 90# petroleum asphalt of Taizhou Hailing District Haizhichun Petrochemical Co., Ltd. or the 90# petroleum asphalt of Maoming Petrochemical or the 90# petroleum asphalt of Jiujiang Petrochemical.

[0066] Asphalt B is the 10# construction petroleum asphalt of Sinopec or the 10# construction petroleum asphalt of Maoming Petrochemical or the 10# construction petroleum asphalt of Qilu Petrochemical.

[0067] The polymer emulsion is a mixture of CRL50LK cationic neoprene latex from Shanghai Jucheng Chemical Co., Ltd. and vinyl acetate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com