Process for producing film

A manufacturing method and film technology, applied in the field of transparent film and its manufacturing, can solve the problems of breakage, low elongation, low tensile strength and the like of the base film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0280] The present invention will be specifically described below through examples, but the present invention is not limited thereto.

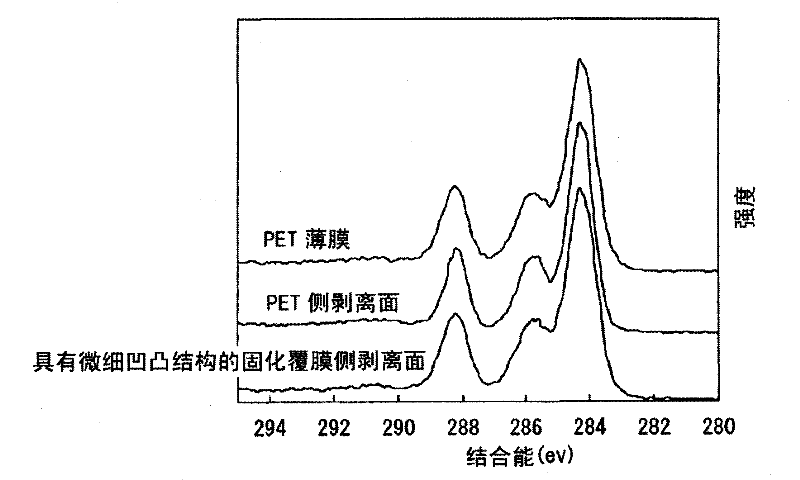

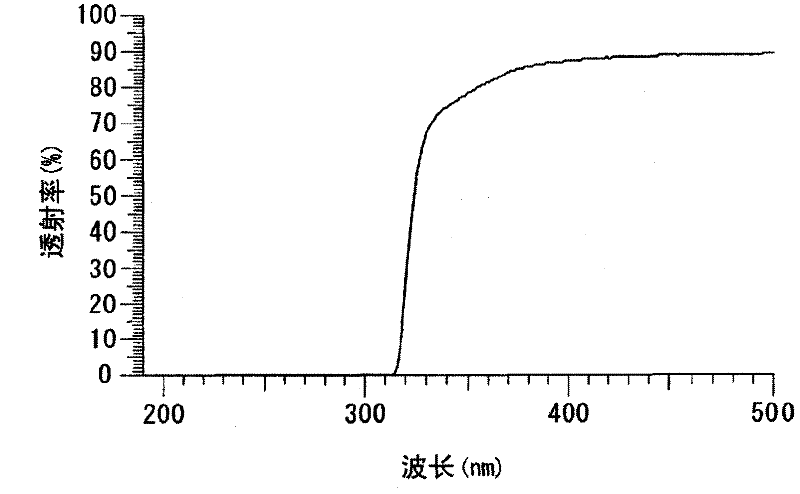

[0281] (1) First, how the influence of ultraviolet rays on the organic release agent varies depending on the type of base film was investigated.

[0282] (die a)

[0283] A 50 mm square aluminum plate (purity: 99.99%) was mirror-polished.

[0284] Process (a):

[0285] The said aluminum plate was anodized in 4.5 mass % oxalic-acid aqueous solution for 6 hours on the conditions of direct current: 40V, temperature: 16 degreeC.

[0286] Process (b):

[0287] The aluminum plate on which the oxide film was formed was immersed in a mixed aqueous solution of 6% by mass phosphoric acid / 1.8% by mass chromic acid at 70° C. for 6 hours to remove the oxide film.

[0288] Process (c):

[0289] The aluminum plate was anodized for 30 seconds in a 2.7% by mass oxalic acid aqueous solution under conditions of direct current: 40V and temperature: 16°C.

...

Embodiment 1

[0348] use Figure 7 The fabrication setup shown in was used to fabricate transparent films.

[0349] As the roll-shaped die 22, the above-mentioned die b was used.

[0350] As the active energy ray-curable resin composition 21, the above-mentioned active energy ray-curable resin composition A is used.

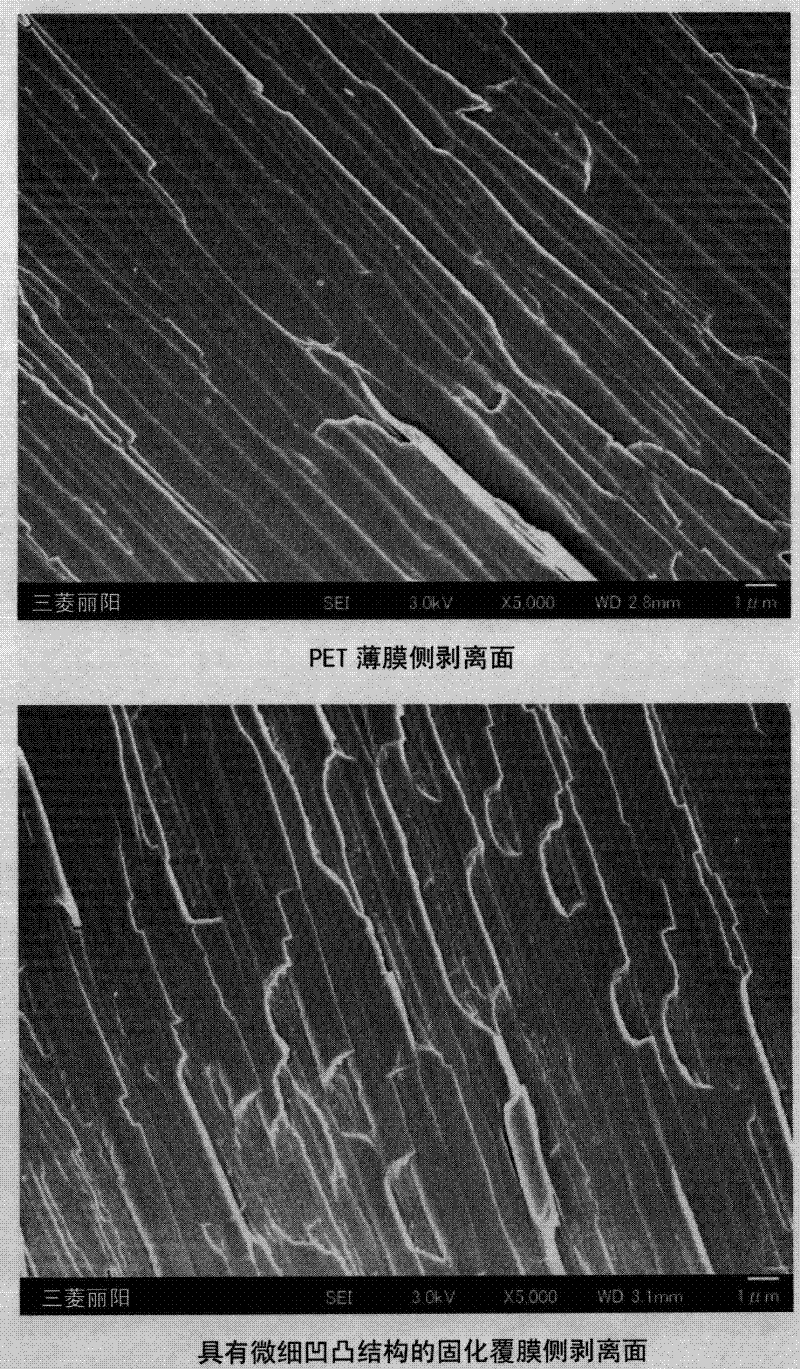

[0351] As the base film 18 supported by the supporting film 17, a PET film (Sun A. A film made of Kaken Co., Ltd., trade name: SAT116, thickness: 38 μm). Among them, the acrylic film used a film obtained as follows: using such as Figure 9 The illustrated scoring spray device includes a brush roll 50 having a concave-convex shape formed of titanium oxide on its surface and tension rolls 52 and 54 arranged in front of and behind the brush roll 50. Rotate in the opposite direction, at the same time, to roughen the surface of the acrylic film, thus obtaining the film. The above-mentioned device can adjust the surface roughness by changing the tension applied on the acrylic f...

Embodiment 2

[0359] A transparent film was produced in the same manner as in Example 1 except that the PET film with a release layer was bonded to the acrylic film using an acrylic forming agent and the surface of the acrylic film was not roughened. As a result, a transparent film equivalent to that of Example 1 could be produced continuously and stably.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com