Active amorphous brazing filler metal for brazing ZrB2-SiC ceramic materials, preparation method for active amorphous brazing filler metal and brazing process

A technology of zrb2-sic and solder, which is applied in the direction of manufacturing tools, welding equipment, welding/cutting media/materials, etc., can solve the problems of high brittleness of solder and poor performance at room temperature, and achieve excellent flexibility and improve wetting ability , Intensify the effect of elemental diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

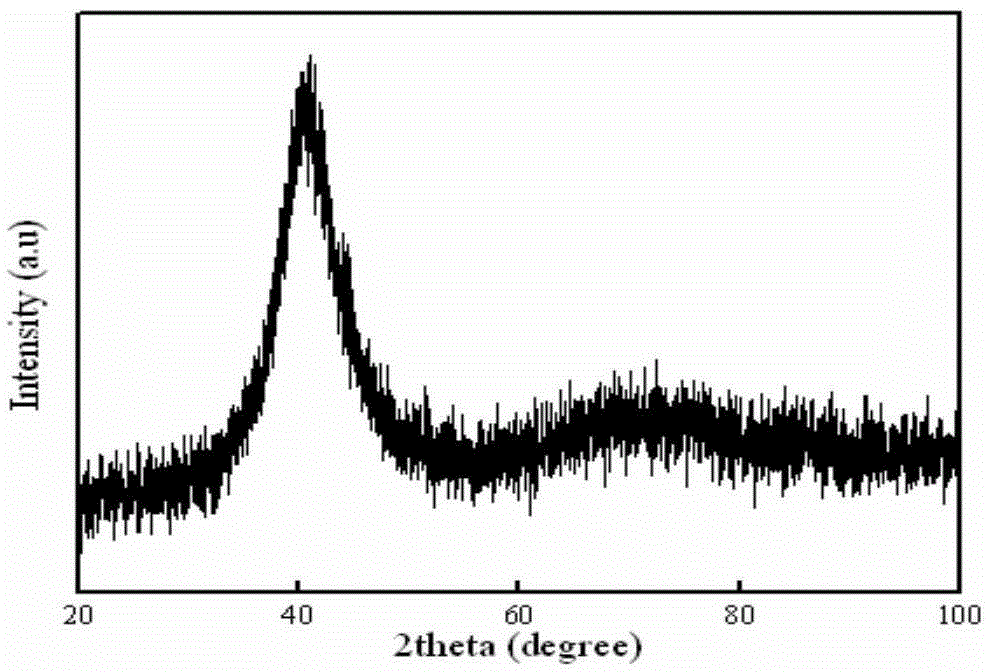

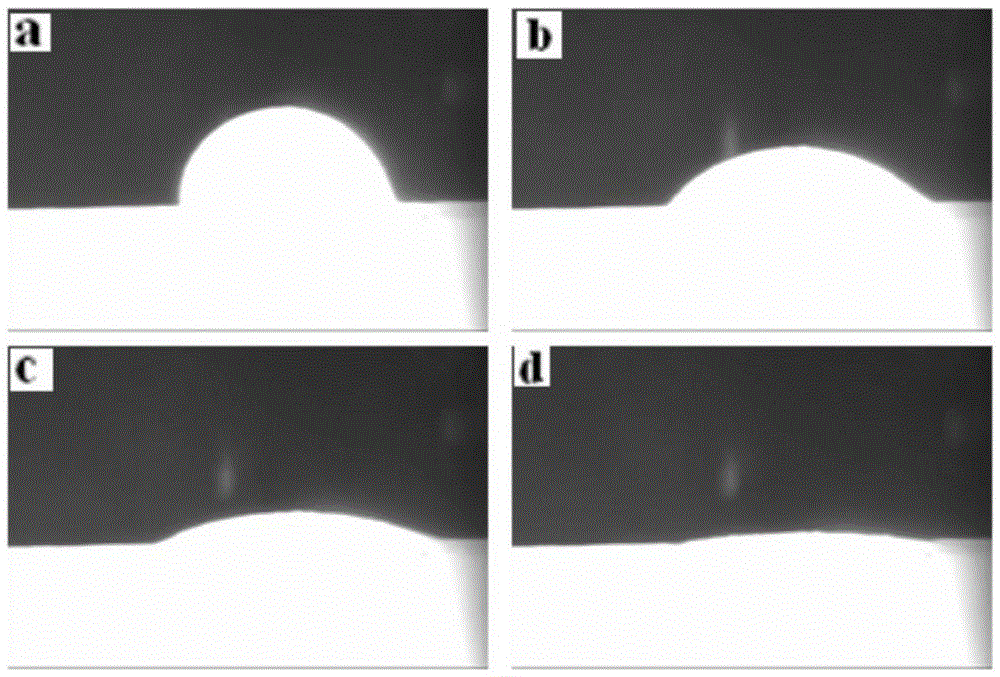

[0045] A kind of brazing ZrB 2 -Active amorphous solder for SiC ceramics, its composition and content by atomic percentage are: Cu: 39.0%; Ti: 35.0%; Zr: 19.0%; the rest is Ni.

[0046] The preparation method is carried out according to the following steps and process:

[0047] (1) After pulverizing the electrolytic copper block (Cu), sponge titanium (Ti), zirconium iodide (Zr) and nickel sheet (Ni), weigh the raw materials on the electronic balance according to the above formula, the purity of Cu, Ti and Ni Above 99.9%, the purity of Zr reaches above 99.99%;

[0048] (2) Place the ingredients according to the above formula in the vacuum magnetron tungsten electric arc furnace in the combined equipment of DHL-500II electric arc furnace stripping machine. There are five stations (semi-spherical sockets) in the electric arc furnace, and three Alloy station (with magnetic stirring), one suction casting station, one smelting and degassing station, in which the sponge titanium sa...

Embodiment 2

[0068] A kind of brazing ZrB 2 -Active amorphous solder for SiC ceramics, its components and contents are as follows: Cu: 36.0%; Ti: 30.0%; Zr: 23.0%; the rest is Ni.

[0069] Brazing process is identical with brazing process described in embodiment 1, adopts the ZrB of this amorphous solder vacuum brazing 2 -SiC ultra-high temperature ceramic material, its room temperature shear strength can reach up to 143MPa.

Embodiment 3

[0071] A kind of brazing ZrB 2 -Active amorphous solder for SiC ceramics, its components and contents are as follows: Cu: 42.0%; Ti: 35.0%; Zr: 16.0%; the rest is Ni.

[0072] Brazing process is identical with brazing process described in embodiment 1, adopts the ZrB of this amorphous solder vacuum brazing 2 -SiC ultra-high temperature ceramic material, its room temperature shear strength can reach up to 124MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com