Hollow fiber composite membrane of ultrathin active layer and preparation method thereof

A fiber composite, active layer technology, applied in the field of ultra-thin active layer hollow fiber composite membrane and its preparation, can solve the problems of poor mechanical strength, low separation performance, poor bonding between polymer separation membrane and base membrane, etc. Industrialized production, simple preparation process and high peeling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Pretreatment of the surface of the polysulfone hollow fiber membrane with a dense cortex:

[0040] Soak the polysulfone hollow fiber membrane with a dense cortex in absolute ethanol for 10 minutes to remove possible organic impurities on the surface of the fiber membrane, then take it out and place it in a clean environment for at least 24 hours to let it dry naturally.

[0041] 2. Configure the film-making solution:

[0042] First, add perfluorosulfonic acid resin powder into a solvent system with a mass ratio of ethanol and distilled water of 80:20, stir to dissolve it completely, and prepare a solution with a mass concentration of 5% and a viscosity of 10 mPa·s. The solution is purified by pressure filtration through a porous filter membrane to remove impurities in the solution to obtain a membrane-forming solution.

[0043] 3. Composite film preparation

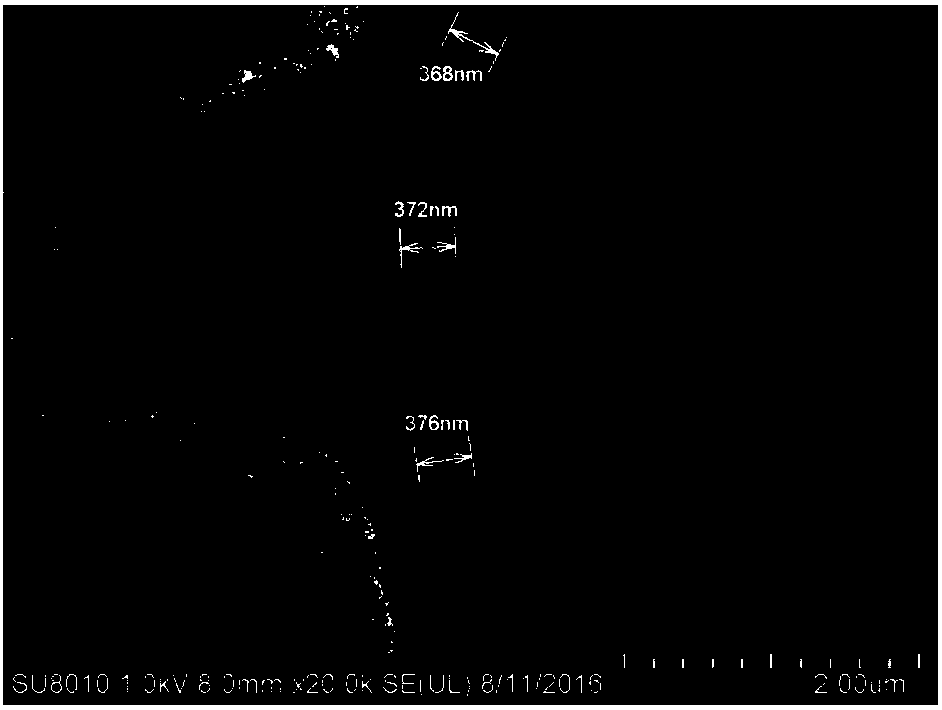

[0044] (1) After the membrane-making solution is left to defoam, the porous polymer membrane obtained throu...

Embodiment 2

[0049] 1. Pretreatment of the surface of the polyacrylonitrile hollow fiber membrane with dense cortex:

[0050] Soak the polyacrylonitrile hollow fiber membrane with a dense skin in absolute ethanol for 30 minutes to remove possible organic impurities on the surface of the fiber membrane, then take it out and place it in a clean environment for at least 24 hours to let it dry naturally.

[0051] 2. Configure the film-making solution:

[0052] First, add perfluorosulfonic acid resin powder into a solvent system with a mass ratio of ethanol and distilled water of 90:10, stir to dissolve it completely, and prepare a solution with a mass concentration of 10% and a viscosity of 100 mPa·s. The solution is purified by pressure filtration through a porous filter membrane to remove impurities in the solution to obtain a membrane-forming solution.

[0053] 3. Composite film preparation

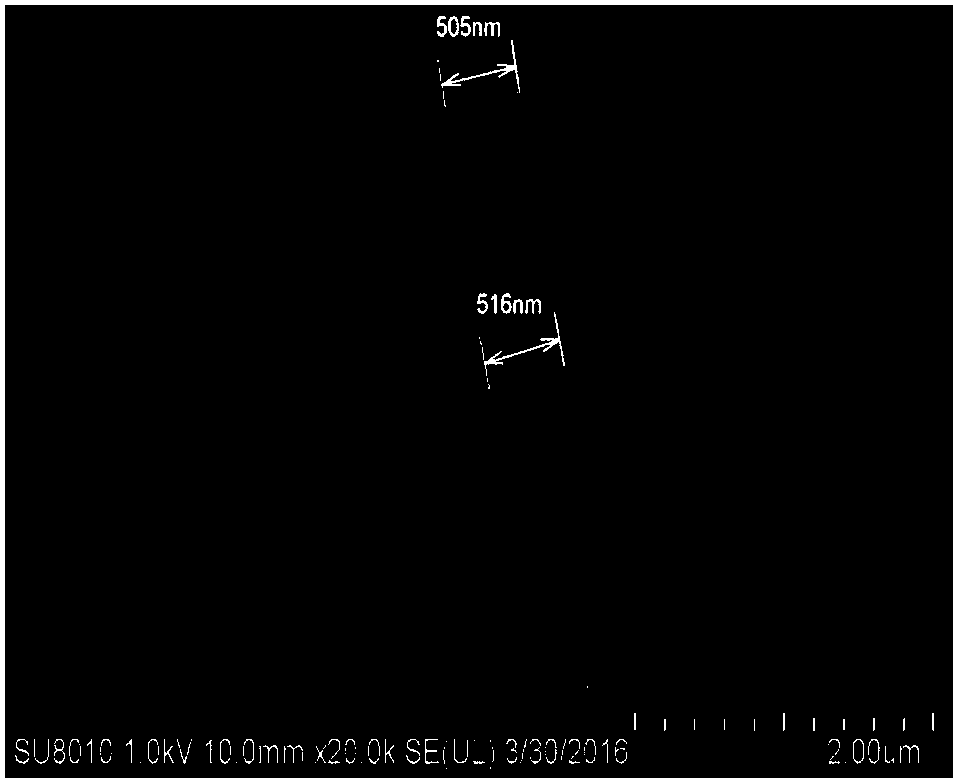

[0054] (1) After the membrane-making solution is left to defoam, the porous polymer membrane obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com