Impacting-resistant and abrasion-resistant concrete prefabricated road

A concrete and pre-installed technology, applied in the direction of roads, roads, road construction reinforcements, etc., can solve the problems of difficult product quality assurance, long seasonal downtime, and large environmental pollution.

Active Publication Date: 2015-12-02

惠州大亚湾市政基础设施有限公司

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Low production efficiency, consume a lot of human resources, long construction period

On-site construction mainly adopts manual work, and product quality is not easy to guarantee

Great environmental pollution, on-site concrete pouring produces noise, sewage, waste and other environmental pollution

When the pavement is demolished or abandoned, the pavement materials will form construction waste, which cannot be reused, resulting in a waste of resources

Construction is greatly affected by the climate

Rainy and cold seasons are unfavorable for construction, resulting in longer seasonal downtime

Therefore, the above shortcomings of cast-in-place concrete roads have become a bottleneck restricting the industrialization of concrete roads

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0049] Example 1: 450 parts of cement, 70 parts of fly ash, 700 parts of sand, 100 parts of water, 0.4 parts of nylon fiber, 15 parts of barium nitrate, 13 parts of calcium lignosulfonate, 16 parts of silicon carbide powder, and 11 parts of sepiolite powder 2 parts, 2 parts of aluminum silicate fiber, 20 parts of gypsum.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Login to View More

Abstract

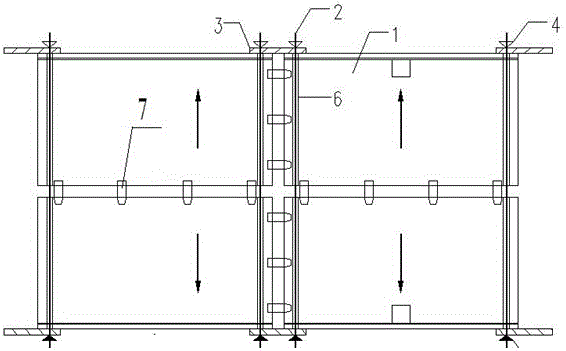

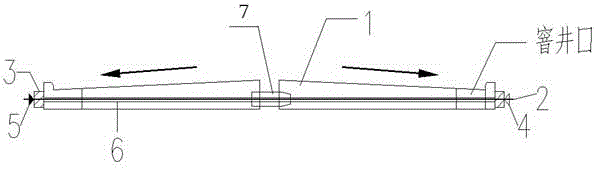

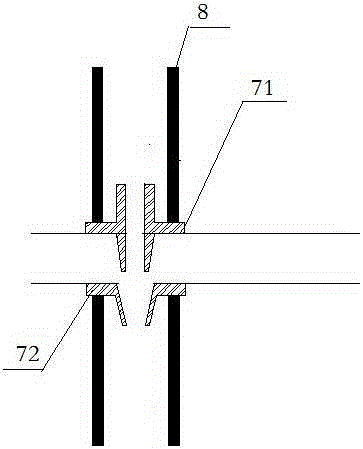

The invention discloses an impacting-resistant and abrasion-resistant concrete prefabricated road. The impacting-resistant and abrasion-resistant concrete prefabricated road comprises four prefabricated boards. Holes where steel strands are contained are formed in the two sides of the prefabricated boards respectively. The adjacent prefabricated boards are connected through the steel strands. The diameter of the steel strands is 14.50 mm. Or holes where the steel strands are contained are formed in the four sides of the prefabricated boards, and the adjacent prefabricated boards are connected through the steel strands. The four prefabricated boards form a road surface unit through the corresponding steel strands and steel connecting board bands on the outer sides of the prefabricated boards. Connecting key structures are further installed between the adjacent prefabricated boards. Each connecting key structure comprises a shearing-resisting convex key and a shearing-resisting concave key which are matched. The prefabricated boards are made of cement, coal ash, sand, water, nylon fibers, barium nitrate, calcium lignosulphonate, silicon carbide powder, sepiolite powder, alumina silicate fibers and gypsum.

Description

technical field [0001] The invention relates to an impact-resistant and wear-resistant concrete pre-installed road. Background technique [0002] my country's economy is currently in a period of rapid development. A large number of roads of various grades are built every year, and a large part of them are concrete roads. At present, the domestic concrete road mainly adopts the construction technology of cast-in-place concrete, which requires construction processes such as on-site support of formwork, binding of steel bars, concrete pouring, and concrete curing. The main disadvantages of the cast-in-place concrete production process are as follows: [0003] The production efficiency is low, a lot of human resources are consumed, and the construction period is long. The on-site construction mainly adopts manual work, and the product quality is not easy to guarantee. The environmental pollution is large, and the on-site concrete pouring produces noise, sewage, waste and othe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E01C5/06E01C11/18C04B28/00

CPCC04B28/02C04B2111/0075C04B2111/20E01C5/003E01C5/06E01C5/065C04B18/08C04B14/06C04B16/0691C04B22/085C04B24/18C04B14/324C04B14/042C04B14/4656C04B14/365

Inventor 孙欣

Owner 惠州大亚湾市政基础设施有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com