Polarized film, and method for manufacturing polarizer

A manufacturing method and polarizing film technology, applied to polarizing elements, chemical instruments and methods, and flat products, can solve problems such as film breakage, poor water removal, and poor appearance of polarizing films, and achieve fewer defects, excellent production efficiency, and high quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

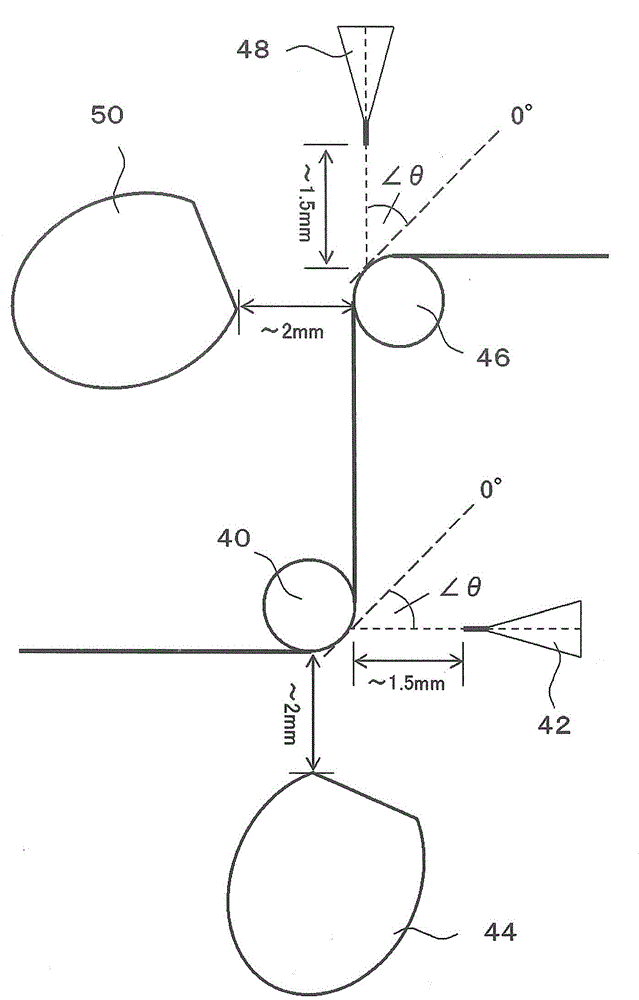

[0132] A polyvinyl alcohol film with a thickness of 60 μm (trade name "kuraray Vinylon VF-PE#6000" manufactured by Kuraray Co., Ltd., a degree of polymerization of 2400, and a degree of saponification of 99.9 mol% or more) was kept in a tense state in a 30- ℃ pure water in a swelling tank for 100 seconds to fully swell the membrane. Then, after dipping in a 30° C. dyeing tank with iodine / potassium iodide / water in a weight ratio of 0.02 / 1.5 / 100 for 90 seconds and simultaneously performing uniaxial stretching, the potassium iodide / boric acid / water in a weight ratio of 12 / 4.4 / 100 in a cross-linking bath at 55°C for 60 seconds, and then uniaxially stretched while performing water-resistant treatment until the cumulative stretching ratio from the original roll reached 5.5 times. Next, after immersing for 10 seconds in a 40° C. boric acid aqueous solution having a weight ratio of boric acid / potassium iodide / water of 9.0 / 2.9 / 100, it was immersed for 2 seconds in a washing tank fille...

Embodiment 2

[0134] Using a polyvinyl alcohol film with a thickness of 50 μm (trade name "kuraray Vinylon VF-PE#5000" manufactured by Kuraray Co., Ltd., degree of polymerization 2400, degree of saponification 99.9 mol%), the tension applied to the film in the water removal treatment was changed. Except having been 500 N / m, it carried out similarly to Example 1, and produced the polarizing film. Transmission inspection of the obtained polarizing film revealed that the number of defects larger than 100 μm was 0.05 pieces / m 2 .

Embodiment 3

[0136] Using a polyvinyl alcohol film with a thickness of 30 μm (trade name "kuraray Vinylon VF-PE#3000" manufactured by Kuraray Co., Ltd., degree of polymerization 2400, degree of saponification 99.9 mol%), the tension applied to the film in the water removal treatment was changed Except having been 450 N / m, it carried out similarly to Example 1, and produced the polarizing film. Transmission inspection of the obtained polarizing film revealed that the number of defects larger than 100 μm was 0.10 pieces / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com