High-temperature-resistant printing material and application thereof

A printing material and high-temperature-resistant technology, applied in additive processing, coating, etc., can solve the problems of high cost, large particles, affecting performance, etc., and achieve the effects of strong adhesion, good thermal matching performance, and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

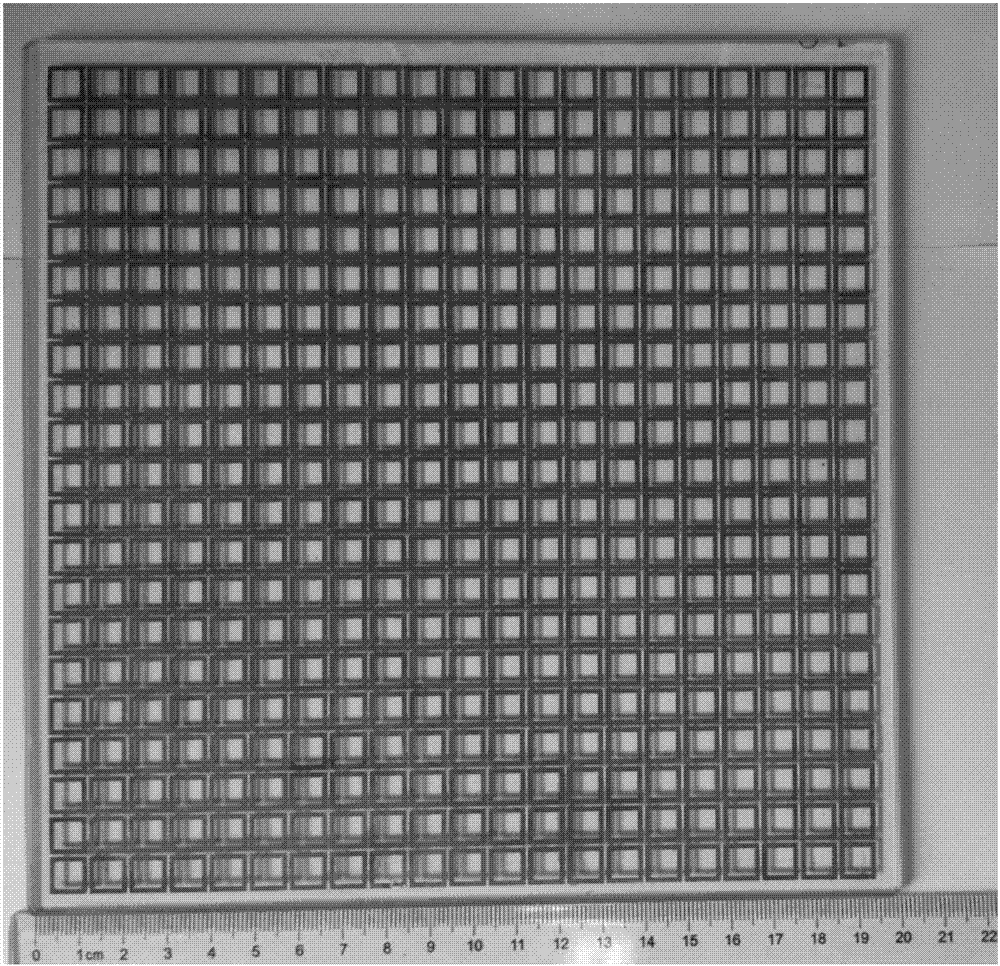

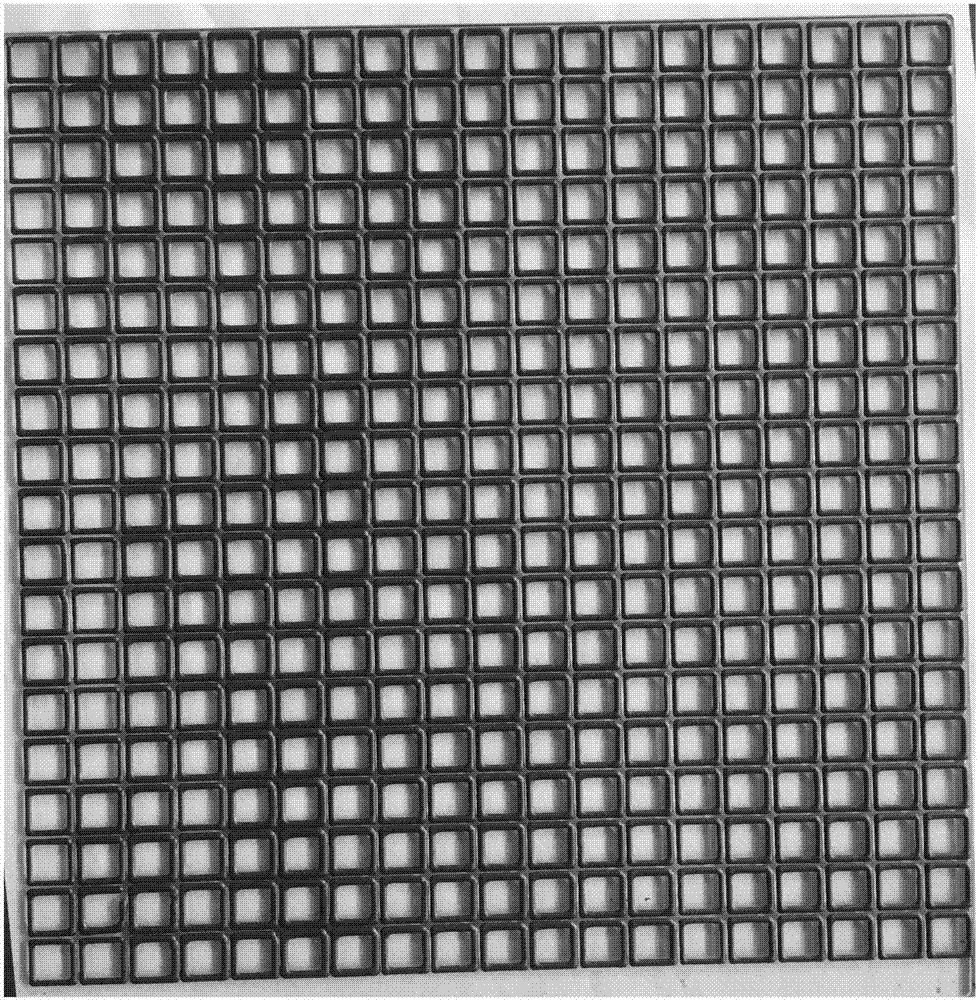

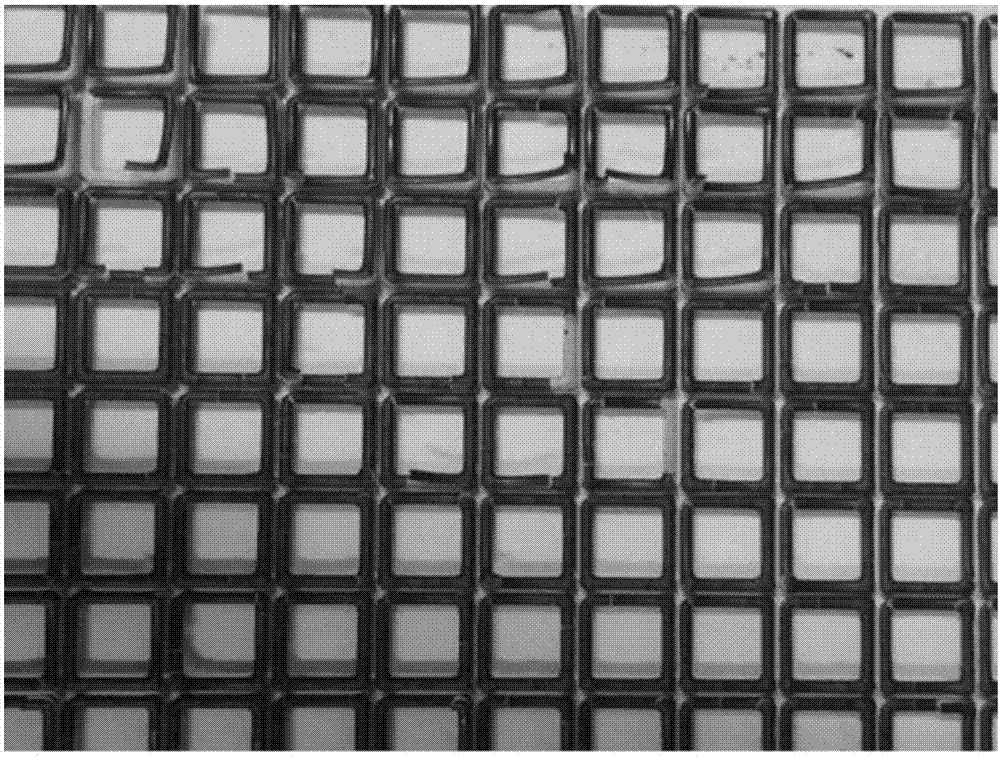

Image

Examples

Embodiment 1

[0029] Take 10 parts of water glass according to the mass ratio, 1 part of graphite powder with a particle diameter of 1 μm, and magnetically stir for 20 minutes to obtain a mixed liquid; the obtained mixed liquid is ball-milled with a planetary ball mill, and the ball-milling time is 30 minutes, and the ball-milling speed is 500r / min to obtain The uniformly mixed high temperature resistance type suspension is ready for use.

[0030] The obtained suspension is printed on the surface of the quartz glass substrate by screen printing process, the screen used is a 250-mesh water-based screen, and printed by hand to obtain a substrate with a specific pattern; the substrate is dried in an oven. The heating rate is 2°C / min, and the temperature is raised to 200°C and then kept for 3 hours, so as to obtain a solidified printed pattern with extremely low porosity; in order to improve its high temperature stability and remove the low melting point impurities and bound water, the substrate...

Embodiment 2

[0033] Take 10 parts of water glass according to the mass ratio, 3 parts of graphite powder with a particle diameter of 1 μm, and magnetically stir for 20 minutes to obtain a mixed liquid; the obtained mixed liquid is ball-milled with a planetary ball mill, and the ball-milling time is 30 minutes, and the ball-milling speed is 500r / min, to obtain The uniformly mixed high temperature resistance type suspension is ready for use.

[0034] The obtained suspension is printed on the surface of the quartz glass substrate by screen printing process, the screen used is a 250-mesh water-based screen, and printed by hand to obtain a substrate with a specific pattern; the substrate is dried in an oven. The heating rate is 2°C / min, and the heat is kept at 200°C for 6 hours to obtain a solidified printed pattern with extremely low porosity; in order to improve its high temperature stability and remove low melting point impurities and bound water, the substrate needs to be processed High-tem...

Embodiment 3

[0036]Take 10 parts of water glass according to the mass ratio, particle diameter is 6 parts of graphite powder of 1 μm, magnetic force stirs 20min, obtains mixed liquid; The mixed liquid that obtains is ball-milled with planetary ball mill, ball-milling time is 30min, and ball-milling speed is 500r / min, obtains The uniformly mixed high temperature resistance type suspension is ready for use.

[0037] The obtained suspension is printed on the surface of the quartz glass substrate by screen printing process, the screen used is a 250-mesh water-based screen, and printed by hand to obtain a substrate with a specific pattern; the substrate is dried in an oven. The heating rate is 2°C / min, and the heat is kept at 200°C for 10 hours to obtain a solidified printed pattern with extremely low porosity; in order to improve its high temperature stability and remove low melting point impurities and bound water, the substrate needs to be processed High-temperature heat treatment, the heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com