Conductive silver paste for fine line laser etching for capacitive type touch screen

A capacitive touch screen, conductive silver paste technology, applied in the direction of circuit, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of rough edges of lines, large silver powder particles, etc., and achieve smooth surface , The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

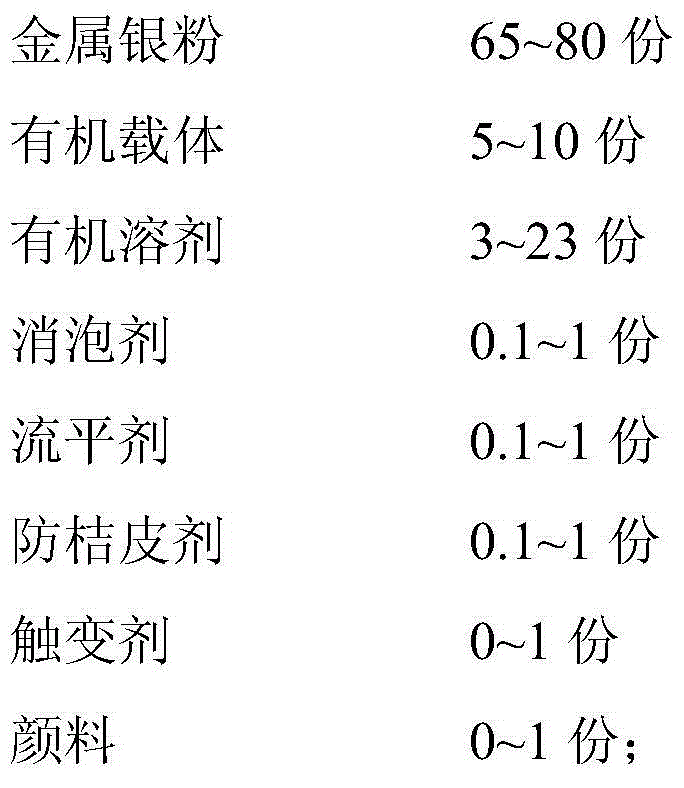

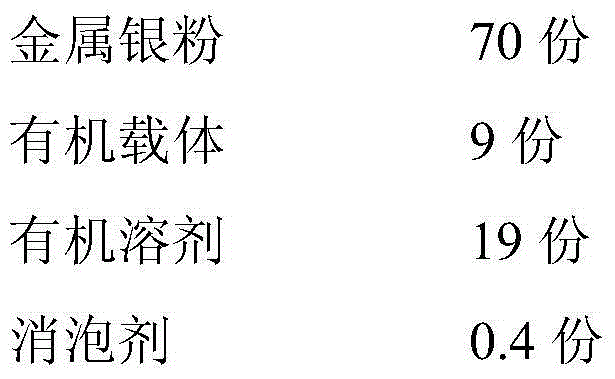

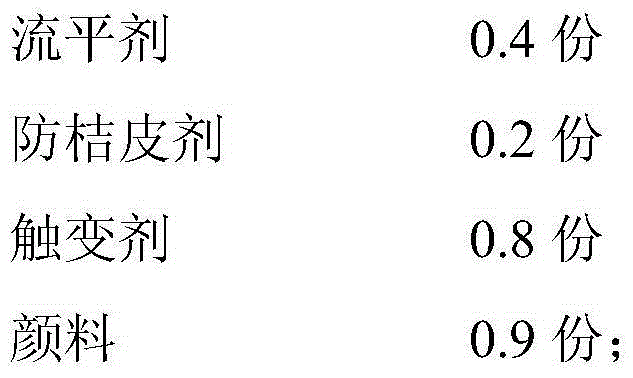

[0029] In this embodiment, a conductive silver paste for laser etching of fine lines of a capacitive touch screen comprises the following components and contents in parts by weight: 70 parts of metallic silver powder, 9 parts of organic vehicle, 19 parts of organic solvent, 0.4 part of defoamer, fluid 0.4 part of leveling agent, 0.2 part of anti-orange peel agent, 0.8 part of thixotropic agent and 0.9 part of pigment.

[0030] Wherein, the metallic silver powder is flake silver powder with a particle size of 0.4 μm and a tap density of 3.8 g / ml.

[0031] The preparation method of the organic carrier is: according to the mass ratio of the polymer resin and the organic solvent as 1:4, add the polymer resin into the organic solvent, heat up to 80°C, keep the temperature constant until the polymer resin is completely dissolved, and then cool to Below 40°C, use a 400-mesh mesh cloth to filter and remove impurities to obtain an organic carrier.

[0032] The polymer resin is polyure...

Embodiment 2

[0055] In this embodiment, a conductive silver paste for laser etching of fine lines of a capacitive touch screen comprises the following components and contents in parts by weight: 70.8 parts of metallic silver powder, 9.4 parts of organic vehicle, 19.6 parts of organic solvent, 0.3 part of defoamer, fluid 0.5 part of leveling agent, 0.3 part of anti-orange peel agent, 0.9 part of thixotropic agent and 1 part of pigment.

[0056] Wherein, the metallic silver powder is flake silver powder with a particle size of 0.6 μm and a tap density of 4 g / ml.

[0057] The preparation method of the organic carrier is: according to the mass ratio of the polymer resin and the organic solvent as 1:4, add the polymer resin into the organic solvent, heat up to 80°C, keep the temperature constant until the polymer resin is completely dissolved, and then cool to Below 40°C, use a 400-mesh mesh cloth to filter and remove impurities to obtain an organic carrier.

[0058] The polymer resin is a sat...

Embodiment 3

[0066] In this embodiment, a conductive silver paste for laser etching of fine lines of a capacitive touch screen comprises the following components and contents in parts by weight: 71 parts of metallic silver powder, 10 parts of organic vehicle, 20 parts of organic solvent, 0.4 part of defoamer, fluid 0.5 part of leveling agent, 0.3 part of anti-orange peel agent, 0.8 part of thixotropic agent and 0.9 part of pigment.

[0067] Wherein, the metal silver powder is a flake silver powder with a particle size of 0.5 μm and a tap density of 3.5 g / ml.

[0068] The preparation method of the organic carrier is: according to the mass ratio of the polymer resin and the organic solvent as 1:3, add the polymer resin into the organic solvent, heat up to 78°C, keep the temperature constant until the polymer resin is completely dissolved, and then cool to Below 40°C, use a 400-mesh mesh cloth to filter and remove impurities to obtain an organic carrier.

[0069] The polymer resin is polyacr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com