HNBR rubber compound for dynamic diaphragm sealing element of oil pump

A technology of diaphragm sealing and mixing rubber, which is applied in the direction of products, educts, reagents, etc., can solve the problems of poor low temperature performance of fluororubber, cost, safety and efficiency inconvenience, high replacement frequency, etc., to achieve excellent sealing performance, methanol and diesel resistance Excellent performance and low volume change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

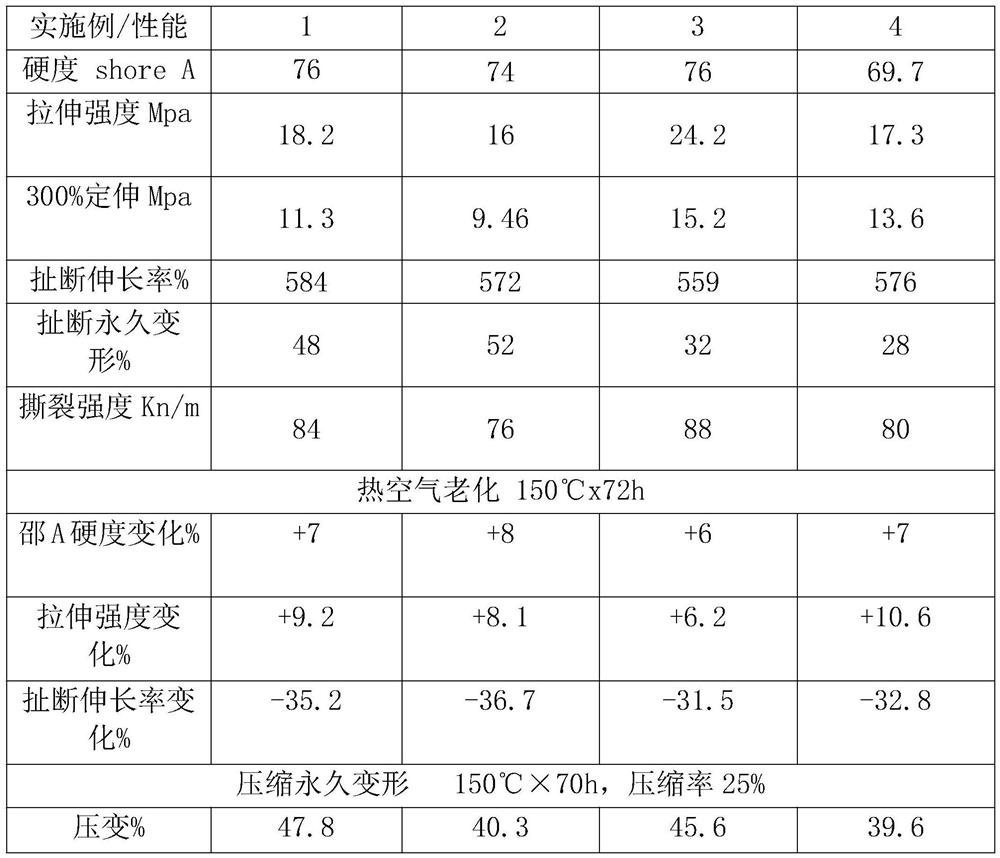

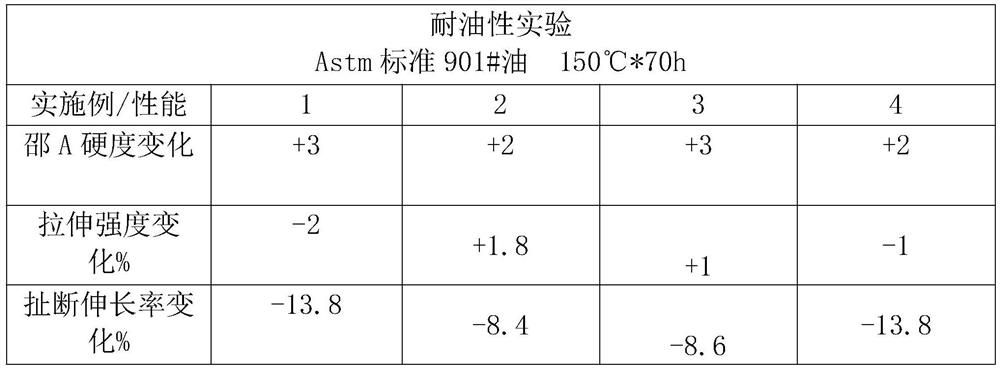

Examples

Embodiment 1

[0026] Step 1: Accurately weigh 18.50kg of hydrogenated nitrile rubber, 1.95kg of MPU, 1.05kg of zinc oxide, 0.20kg of stearic acid, 4450.51kg of diphenylamines, 0.51kg of zinc salt antioxidant MBZ, 13.90kg of carbon black N330, and mix Ether / ester type plasticizer TP-7592.45kg, sulphur 0.12kg, dicumyl peroxide DCP 0.31kg, N-tert-butyl-2-benzothiazole sulfenamide NS 0.30kg, tetramethyl autumnal disulfide Lamb TMTD 0.2kg;

[0027] Step 2: Mix and masticate the hydrogenated nitrile rubber weighed in step 1 and MPU to reach Mooney 70ML (1+4) at 100°C and park for 24 hours to obtain a hydrogenated nitrile rubber mixture;

[0028] Step 3: Add the hydrogenated nitrile rubber mixture obtained in Step 2 and the weighed zinc oxide, stearic acid, diphenylamine 445, and zinc salt antioxidant MBZ into the mixer at a temperature of 120° C. Mixing for 120s under the condition of 25rad / min and 0.6Mpa top bolt pressure; then put carbon black N330 and mixed ether / ester plasticizer TP-759 weig...

Embodiment 2

[0032] Step 1: Accurately weigh 16.70kg of hydrogenated nitrile rubber, 3.00kg of MPU, 0.99kg of zinc oxide, 0.20K of stearic acid, 4450.49kg of diphenylamine, 0.49kg of zinc salt antioxidant MBZ, 13.39kg of carbon black N330, mix Ether / ester type plasticizer TP-7593.55kg, sulfur 0.10kg, dicumyl peroxide DCP 0.30kg, N-tert-butyl-2-benzothiazole sulfenamide NS 0.49kg, tetramethyl ethylene disulfide Lamb TMTD 0.30kg;

[0033] Step 2: Mix and masticate the hydrogenated nitrile rubber weighed in step 1 and MPU to reach Mooney 68ML (1+4) at 100° C. and then park for 24 hours to obtain a hydrogenated nitrile rubber mixture;

[0034]Step 3: Add the hydrogenated nitrile rubber mixture obtained in Step 2 and the weighed zinc oxide, stearic acid, diphenylamine 445, and zinc salt antioxidant MBZ into the mixer at a temperature of 120° C. 25rad / min, under the condition of top bolt pressure of 0.6Mpa, knead for 120s, then add carbon black N330 weighed in step 1, mixed with ether / ester pla...

Embodiment 3

[0038] Step 1: Accurately weigh 18.39kg of hydrogenated nitrile rubber, 3.10kg of MPU, 1.07kg of zinc oxide, 0.21kg of stearic acid, 4450.54kg of diphenylamine, 0.54kg of zinc salt antioxidant MBZ, 10.76kg of carbon black N330, titanium Potassium acid whisker TiSMO 1.72kg, mixed ether / ester plasticizer TP-7592.58kg, sulfur 0.13kg, dicumyl peroxide DCP 0.43kg, N-tert-butyl-2-benzothiazole sulfenamide NS0 .26kg, tetramethylthiuram disulfide TMTD 0.16kg, trimethylolpropane trimethacrylate TP-3500.11kg;

[0039] Step 2: Mix and masticate the hydrogenated nitrile rubber weighed in step 1 and MPU to reach Mooney 70ML (1+4) at 100°C and park for 24 hours to obtain a hydrogenated nitrile rubber mixture;

[0040] Step 3: Add the hydrogenated nitrile rubber mixture obtained in Step 2 and the weighed zinc oxide, stearic acid, diphenylamine 445, and zinc salt antioxidant MBZ into the mixer at a temperature of 120° C. Mixing for 120s under the condition of 25rad / min and top bolt pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com