Multi-phase suspension system, preparation method and application thereof

A mixing and mixing technology, applied in the direction of mixing methods, applications, food preparation, etc., can solve the problems of rubber hardening, soft capsule oil leakage, uneven content, etc., to achieve dry and beautiful surface, less greasy feeling, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

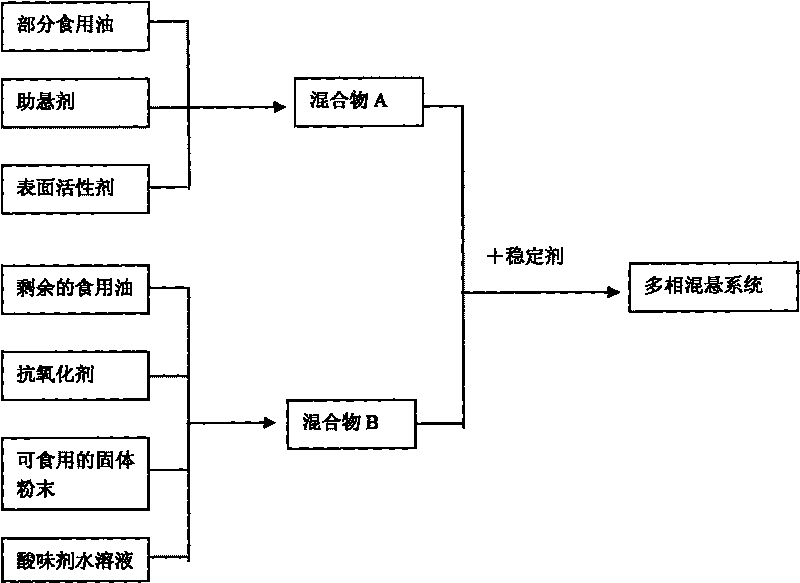

[0049] Preparation of multiphase suspension system with dietary fiber as solid phase, such as figure 1 Shown:

[0050] The raw materials of the content include (all calculated by mass percentage):

[0051] Water-soluble dietary fiber 10%, water-insoluble dietary fiber 30%, beeswax: 1%, soybean oil 54.7%, fructooligosaccharide syrup 2% (dry weight conversion: 1.4%), lecithin 1%, vitamin E 0.2%, Citric acid 0.1%, and water 1%.

[0052] (1) The water-soluble dietary fiber and the water-insoluble dietary fiber are ultrafinely pulverized and sieved to obtain a solid powder with a particle size of 100-160 mesh.

[0053] (2) First mix 1 / 2 of soybean oil and beeswax, then stir and mix at 80°C at 60r / min to dissolve completely, then cool to 50°C, add lecithin, stir and mix at 60r / min to obtain mixture A.

[0054](3) Dissolving citric acid in water, then stirring and mixing with the remaining soybean oil, vitamin E and the solid powder obtained in step (1) at a speed of 800 r / min to ...

Embodiment 2

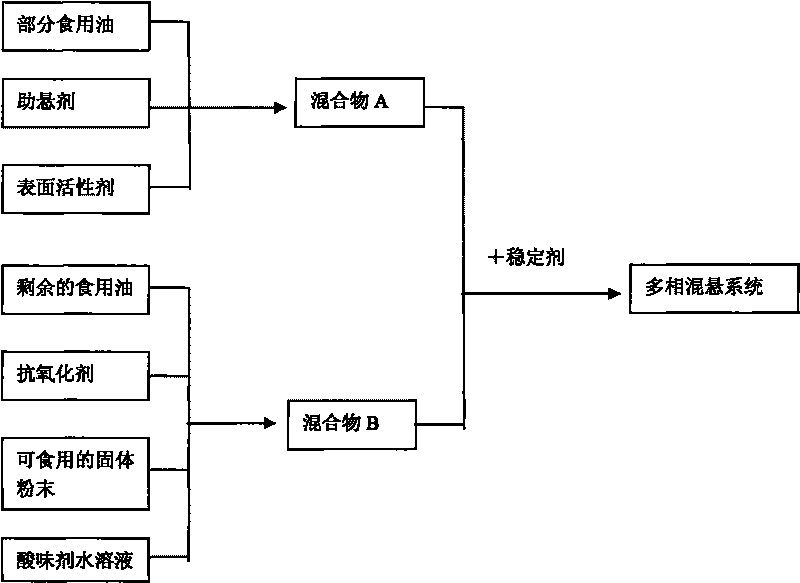

[0071] The preparation of the multiphase suspension system with royal jelly freeze-dried powder as the solid phase is shown in Figure 2:

[0072] The raw materials of the content are as follows (all calculated by mass percentage):

[0073] Royal jelly freeze-dried powder 30%, olive oil 45.98%, sucrose stearate 2%, fructose syrup 10% (6% in dry weight conversion), beeswax 5%, ascorbyl palmitate 0.02%, sodium citrate 1% and water 6%.

[0074] (1) Sieve the freeze-dried royal jelly powder to obtain a solid powder with a particle size of 100-160 mesh.

[0075] (2) First mix 1 / 2 of the olive oil, beeswax and sucrose stearate and stir at 80°C at a speed of 60r / min until completely dissolved to obtain mixture A.

[0076] (3) Sodium citrate was dissolved in water, and then mixed with royal jelly freeze-dried powder, remaining olive oil and ascorbyl palmitate at 40 MPa to obtain mixture B.

[0077] (4) Mix mixture A and mixture B, stir and mix at 120r / min, then add fructooligosaccha...

Embodiment 3

[0080] Preparation of multiphase suspension system with hawthorn powder as solid phase:

[0081] The raw materials of the contents are as follows:

[0082] Hawthorn dry powder 10%, soybean oil 71.4%, sucrose stearate 2.5%, sucrose palmitate 2.5%, beeswax 2.5%, fructooligosaccharide syrup 8% (dry weight conversion: 5.6%), vitamin E 0.1% .

[0083] (1) The dried hawthorn is ultrafinely pulverized and sieved to obtain a solid powder with a particle size of 120-160 mesh.

[0084] (2) Stir soybean oil, sucrose stearate, sucrose palmitate and beeswax at 80° C. at a speed of 60 r / min until completely dissolved to obtain mixture A.

[0085] (3) The hawthorn powder was mixed with the remaining 50% soybean oil and vitamin E by ultrasonic wave, the temperature of the ultrasonic wave was 40° C., and the time was 60 min to obtain the mixture B.

[0086] (4) Mix mixture A and mixture B, stir and mix at 120r / min, then add fructooligosaccharide syrup, stir and mix evenly at a speed of 60r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com