Air flue plate processing device and method

A technology of processing device and air duct plate, applied in the field of machinery, can solve the problems of slow working speed, low working efficiency, easy damage of oil pump, etc., and achieve the effect of high production efficiency, good stability and uniformity, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

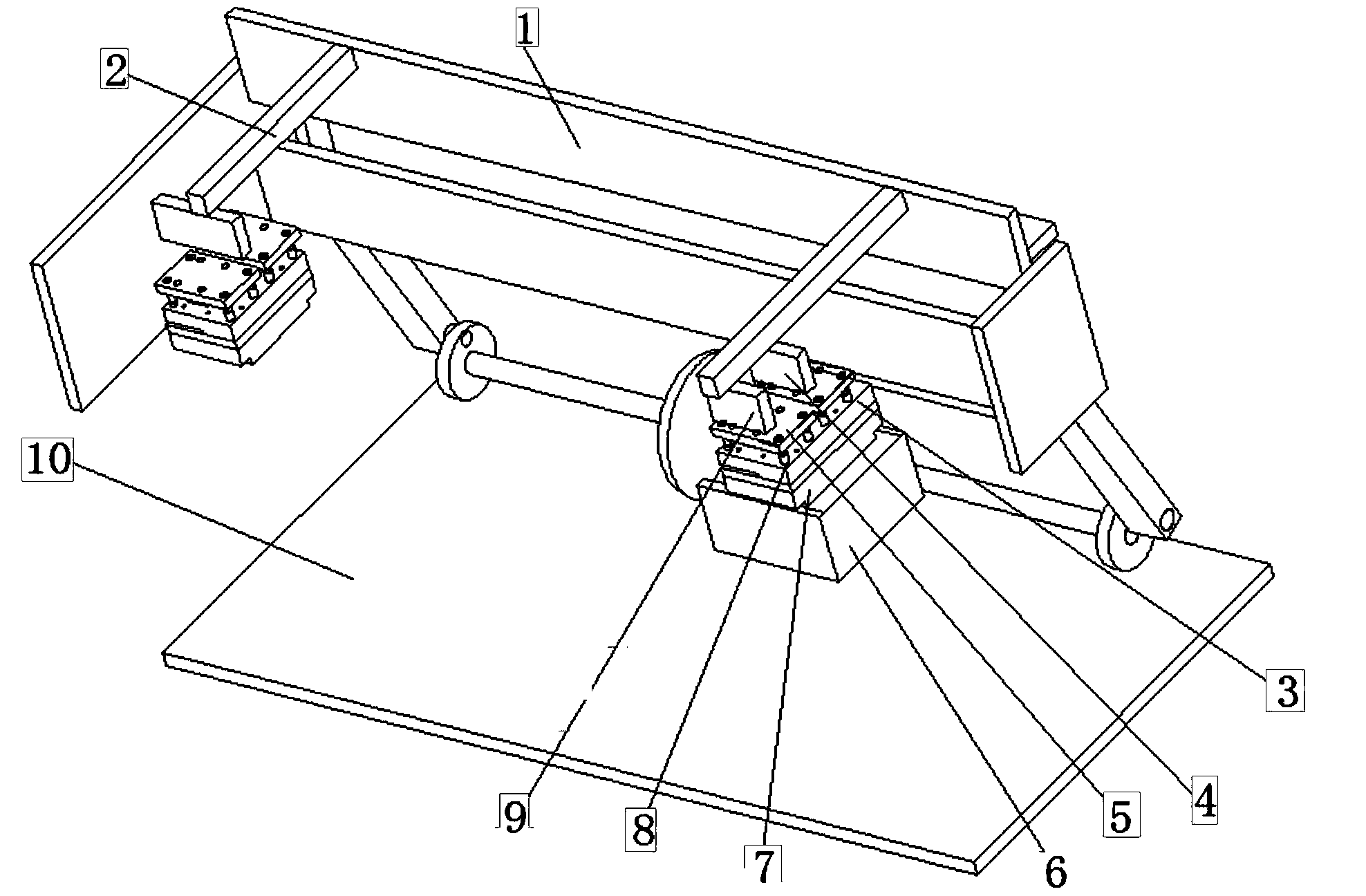

[0037] Embodiment 1; the end of the cylinder shaft extending from the action cylinder is provided with a cylinder gasket 4. The essential technical effect of the technical solutions provided by this office is to provide specific compression solutions, combining figure 1 , figure 2 with Figure 4 , Figure 5 , By using the force device 2 to press the cylinder block 4, the downward force can be realized, and various operation effects can be realized.

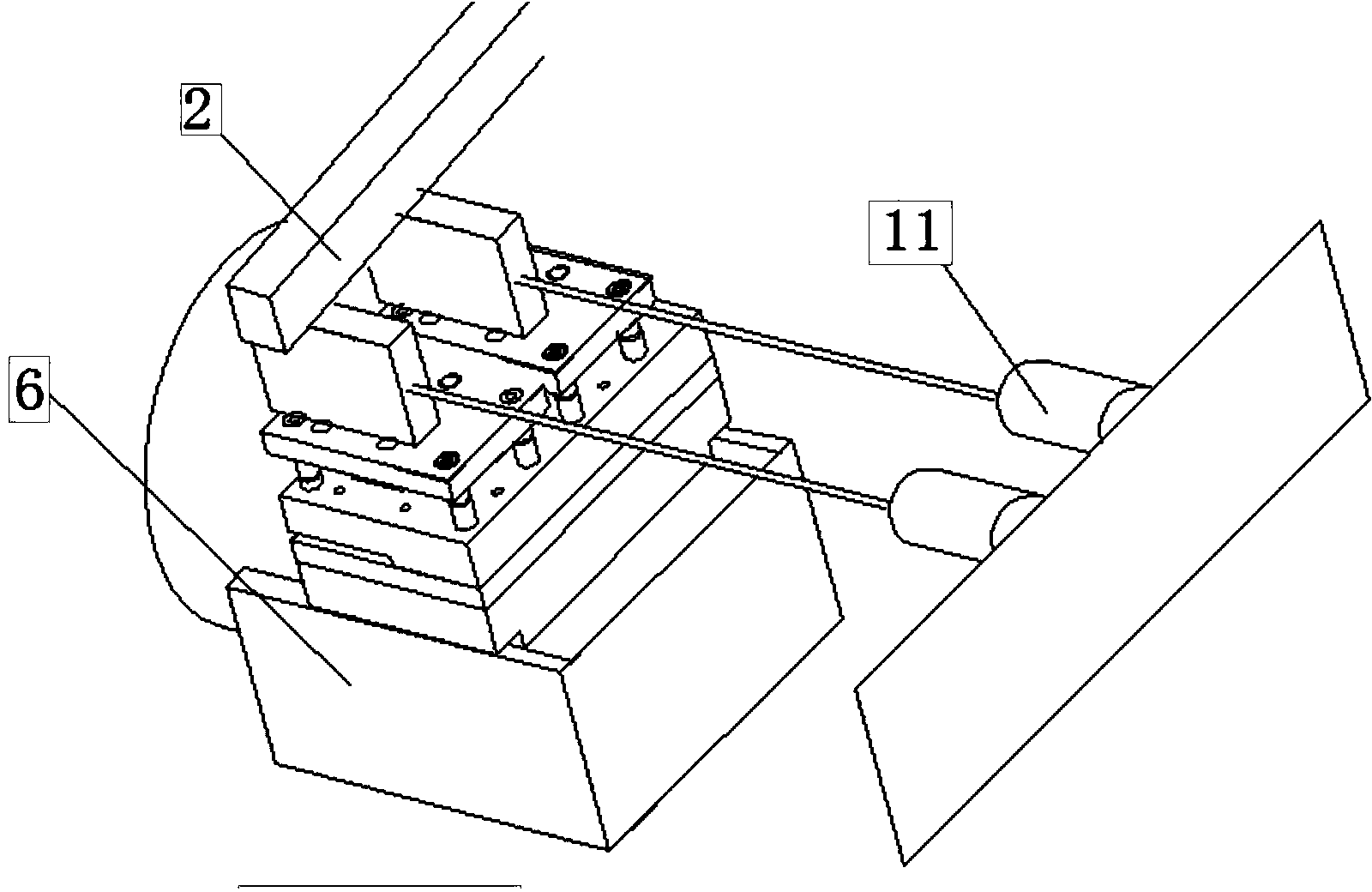

[0038] As an optimization of embodiment 1, the action cylinder is a side cylinder group 11, and the side cylinder group 11 is arranged side by side and installed on a bracket. The cylinder shafts extending from the cylinder shaft are respectively provided with a cylinder head gasket 4 and an adjacent cylinder head gasket 9 There is an upper template 3 under the cylinder head gasket 4 and the adjacent cylinder head gasket 9 respectively, and two upper templates 3 are arranged side by side. Combine figure 2 , And there can be only on...

Embodiment 2

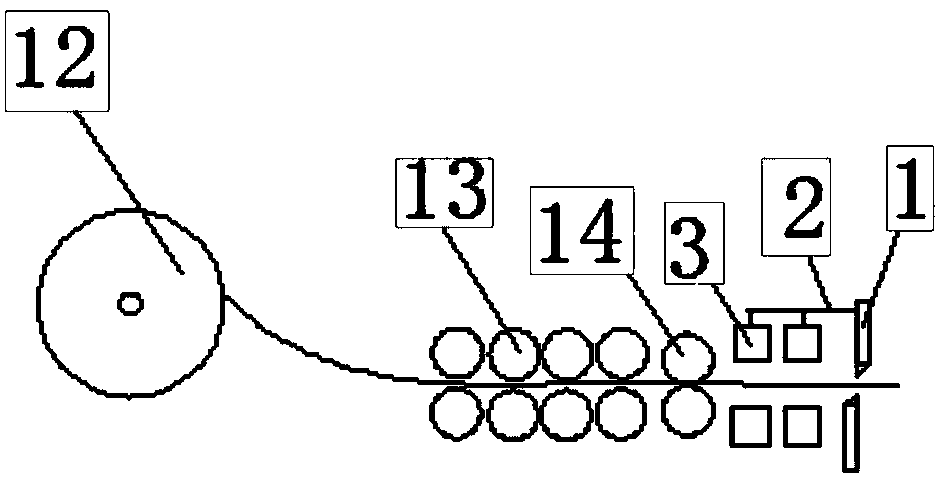

[0039] Example 2, combining Image 6 , The upper template 3 and the lower template 7 placed on the plane are both located on a movable base. The bottom of the movable base includes wheels, and the upper part of the movable base also includes side panels. The side panels have rails, The template 3 can be sleeved on the rail and can move up and down on it, and the shaft of the cylinder is connected to the side plate and can push the side plate to move.

[0040] The overall push-pull method is adopted, so that whether to perform punching with force is optional.

[0041] As a further optimization of Embodiment 1, a slider is included under the lower template 7, the slider is mounted on a rail, the rail is located on the rail platform 6, and the rail platform 6 is fixed on the foundation platform. The essential technical effect of the technical solution here is that the device can process steel plates of different sizes, and it is convenient to change the punching position of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com