Carbon nanotube sponge and preparation method thereof

A carbon nanotube sponge and carbon nanotube technology, applied in the field of carbon nanotube sponge and its preparation, can solve the problems that the carbon nanotube sponge is not a complete elastic body and limit applications, and achieve the effect of easy industrialization and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

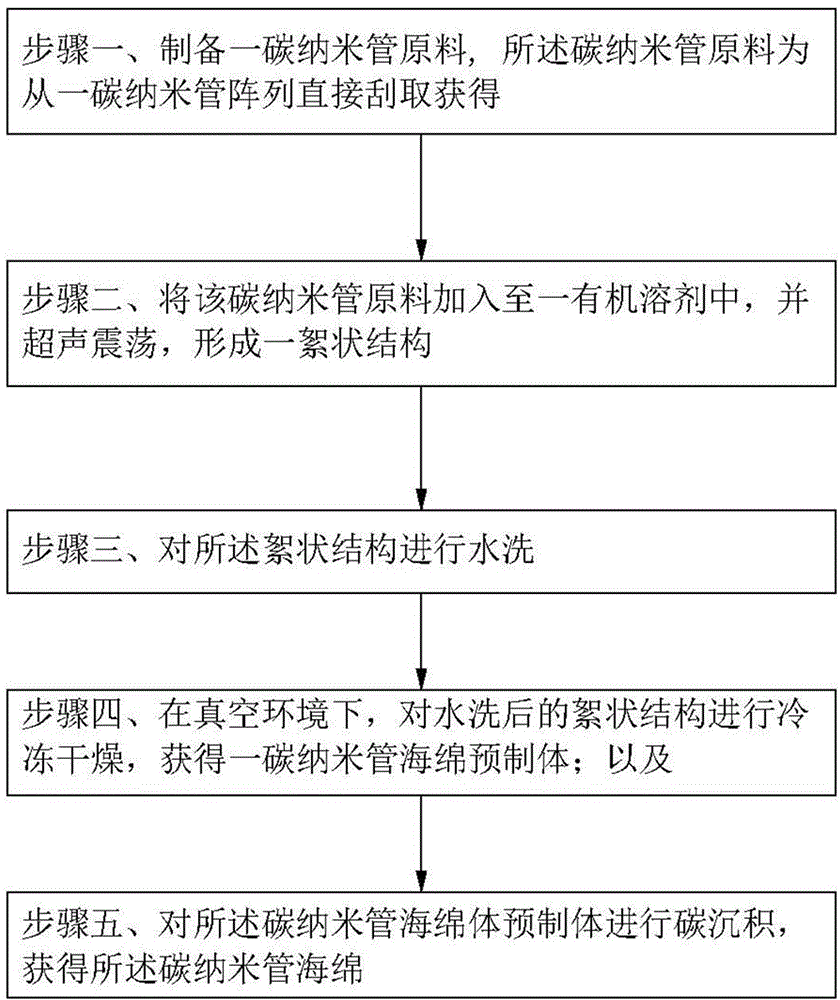

[0025] Please refer to figure 1 , the embodiment of the present invention provides a kind of preparation method of carbon nanotube sponge, comprising:

[0026] Step 1, preparing a carbon nanotube raw material, the carbon nanotube raw material is directly scraped from a carbon nanotube array.

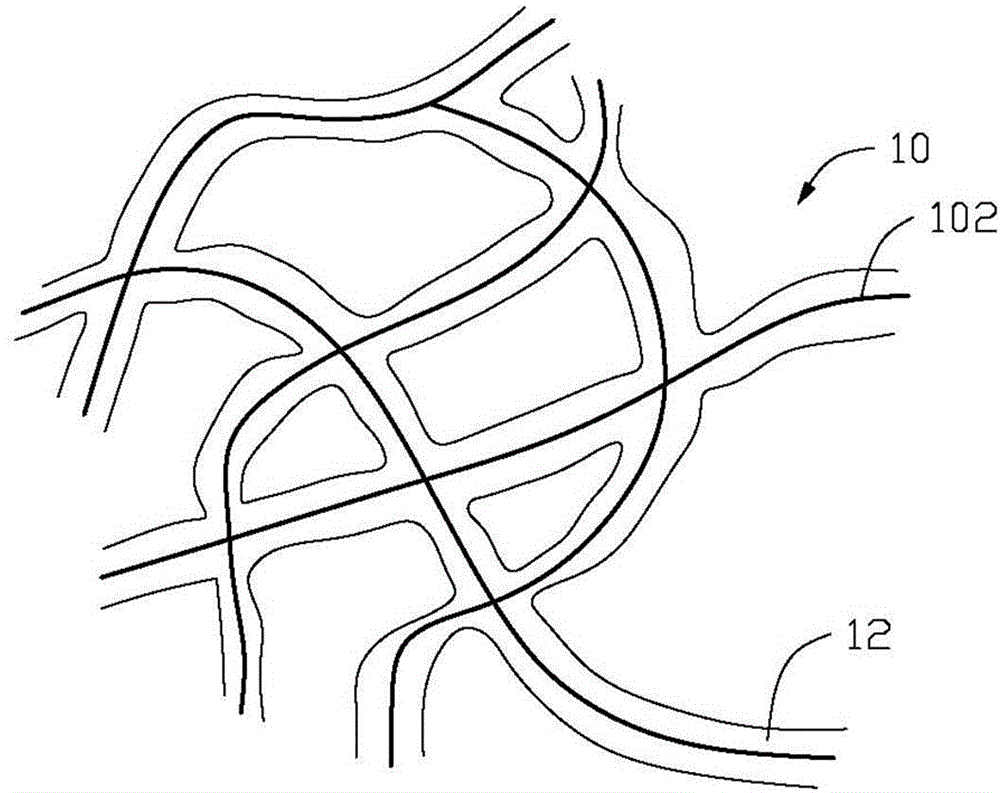

[0027] The carbon nanotube raw material is composed of a plurality of carbon nanotubes, and the carbon nanotubes include single-wall carbon nanotubes, double-wall carbon nanotubes or multi-wall carbon nanotubes. The diameter of carbon nanotubes is 20 nanometers to 30 nanometers. The length of the carbon nanotubes is greater than 100 microns, preferably, the length of the carbon nanotubes is greater than 300 microns. The carbon nanotubes are preferably carbon nanotubes with a pure surface without impurities and without any chemical modification. It is understood that the presence of impurities or chemical modification can destroy the force between carbon nanotubes. The preparation met...

Embodiment 1

[0040] Provide a super-parallel array of carbon nanotubes, the carbon nanotubes in the array of carbon nanotubes have a diameter of 20 nanometers and a length of 300 microns; scrape 200 milligrams of the carbon nanotube arrays, add it to 400 milliliters of ethanol with power Ultrasonic stirring with 500 watts of ultrasonic waves for 30 minutes forms a floc structure; washes the floc structure; puts the washed floc structure into a freeze dryer, and rapidly cools to -60°C; vacuumizes to About 30pa, at this time, at the same time, heat up to -25°C and dry for 2 hours; heat up to -20°C, dry for 2 hours; heat up to -15°C, dry for 2 hours; heat up to -10°C, dry for 2 hours; heat up to - 5°C, dry for 2 hours; heat up to 0°C, dry for 2 hours; heat up to 5°C, dry for 2 hours; heat up to 10°C, dry for 2 hours; heat up to 15°C, dry for 2 hours; Freeze dryer inlet valve, take out the sample, obtain the carbon nanotube sponge preform; transfer the carbon nanotube sponge preform into a rea...

Embodiment 2

[0042] It is basically the same as Example 1, except that the deposition time is 30 minutes. The mass percent content of the carbon deposit layer in the obtained carbon nanotube sponge is about 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com