Comprehensive test device of oil film bearing

A technology of oil film bearings and test equipment, which is applied in the field of oil film bearings, can solve problems such as small frictional resistance, burns, friction and wear of metal parts, and achieve the effect of improving poor oil circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

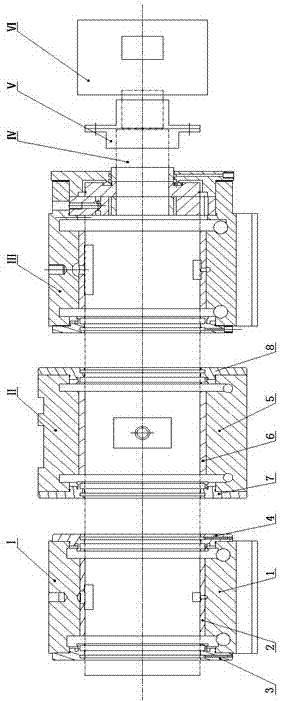

[0022] As shown in Figure 1, the left bearing I and the right bearing III are supporting bearings, which are fixed on the test platform by positioning pins, and the middle bearing II is the loading object for performance testing, suspended on the shaft IV, which is easy to install and align , but also to achieve eccentricity measurement.

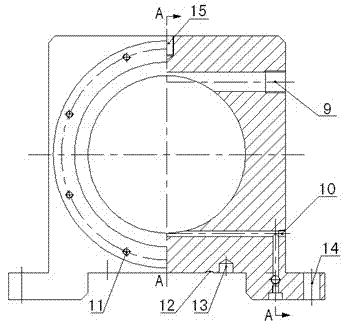

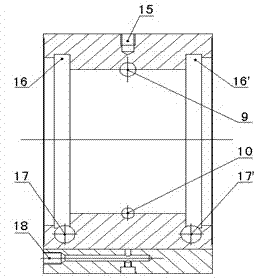

[0023] As shown in Figures 2, 3, 4, and 5, the static pressure oil circuit of the left bearing I is supplied by a high-pressure pump, and the static pressure oil is pumped into the left static pressure inlet through the static pressure oil inlet 18 on the left bearing I. Oil hole 10, then enters the static pressure oil hole 21 through the static pressure oil chamber 22, and establishes a static pressure bearing oil film in the bearing area to bear the external load; the dynamic pressure oil circuit is the dynamic pressure oil through the dynamic pressure on the left bearing I. The pressure oil hole 9 flows through the dynamic pressure oil ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com