Test method and apparatus for polymer power cable insulation accelerated electric tree aging

A power cable and test device technology, which is applied in the field of insulation monitoring of polymer power cables, can solve the problems of large consumables, inability to estimate cables, long aging time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

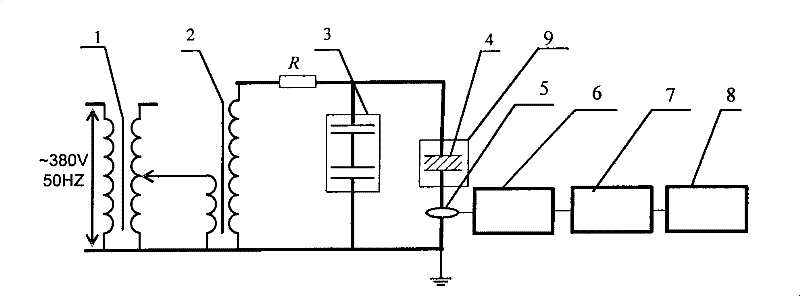

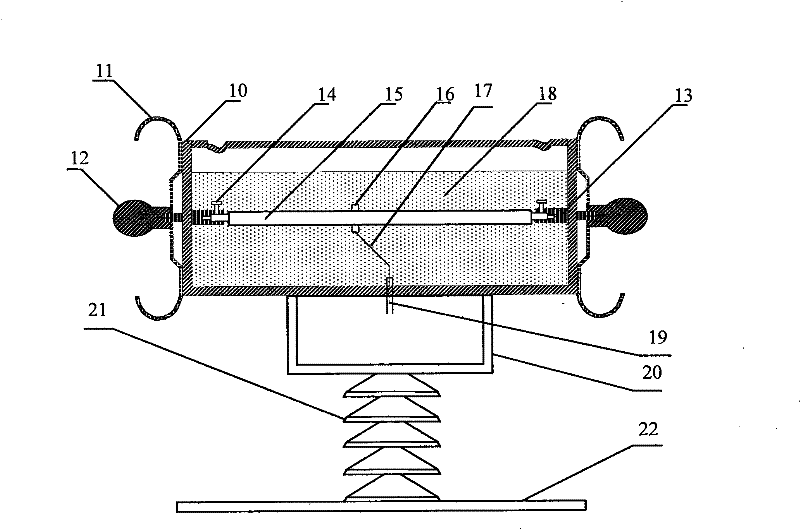

[0065] Such as Figure 1~4 As shown, a test device for accelerated electrical tree aging of polymer power cable insulation, including a non-halo experimental transformer 1, an induction voltage regulator 2, a capacitive voltage divider 3, a test electrode 4, a broadband current sensor 5, and an amplification filter 6. Digital oscilloscope 7. Microcomputer 8. The test electrode 4 is mainly composed of a glass fiber reinforced plastic shell 10, an anti-corona cover 11, a round electrode 12, a cylindrical copper electrode 13, a compression nut 14, a cable sample 15, a terminal clamp 16, a ground connection 17, an insulating oil 18, and an oil drain. Valve 19, insulating bracket 20, post insulator 21 and metal disc base 22 are composed. A top cover is set on the upper end surface of the FRP shell 10, so that the test electrode 4 and insulating oil 18 are injected, and cylindrical copper electrodes are respectively installed at both ends of the center of the FRP shell 10. At both...

Embodiment 2

[0067] A test method for accelerated electrical tree aging of polymer power cable insulation, the specific steps are as follows:

[0068] 1) Test preparation

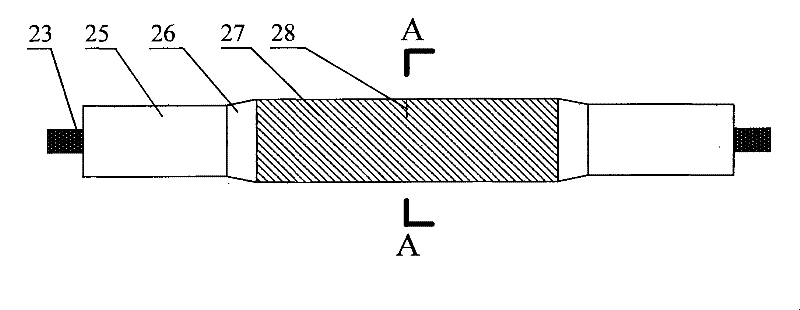

[0069] First cut a section of the polymer power cable, peel off both ends layer by layer, and artificially create a defect 28 on the insulating layer 25 in the center of the cable sample 15, and make a cable sample 15 with the insulation defect 28. First, connect the cable cores 23 at both ends of the cable sample 15 to the two cylindrical copper electrodes 12 of the test electrode 4 through the compression nuts 14 of the test electrode 4, respectively, and connect the copper shielding layer 27 of the cable sample 15 to the ground. The ground connection line 29 is connected with the end of the oil discharge valve 19 in the pressure electrode, and then the electrode system 4 is placed in the combined electric heating aging box 9, and the end of the oil discharge valve 19 outside the test electrode is connected with the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com