Heat conducting polysiloxane composition

A technology of polysiloxane and composition, which is applied in the field of thermally conductive polysiloxane composition, which can solve problems such as heat sinks, heat-generating electronic components, oil spills, etc., and achieve the effect of improving heat resistance and stabilizing the use state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The present invention will be described in more detail below in conjunction with the examples. It should be understood that the present invention should not be considered as limited to these examples.

[0025] Component A:

[0026] Has at least two alkenyl groups in the molecule and a viscosity of 10-100,000mm at 25°C 2 / s organopolysiloxane;

[0027] Component B:

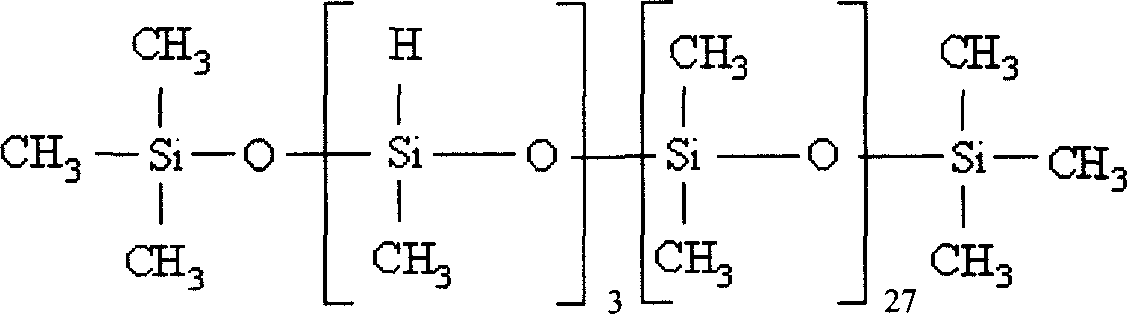

[0028] Organohydrogenpolysiloxanes represented by the following structures:

[0029]

[0030] Component C:

[0031] Aluminum powder with an average particle size of 2 μm;

[0032] Component D:

[0033] Isopropyl triisostearyl titanate.

[0034]When preparing the heat-conducting polysiloxane composition of the present invention, the components A, B, and D are first stirred and mixed at room temperature according to the blending ratio shown in Table 1, so that a certain crosslinking reaction occurs between component A and component B , and then add component C according to the ratio shown in Table 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com