Low-pressure anti-seepage device of gearbox

A kind of gearbox, anti-leakage technology, applied in the direction of transmission parts, belt/chain/gear, mechanical equipment, etc., can solve the problems of environmental equipment pollution, force and deformation of the sub-box surface, bearing heating, etc., so as not to pollute the environment , to achieve automatic control, improve the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

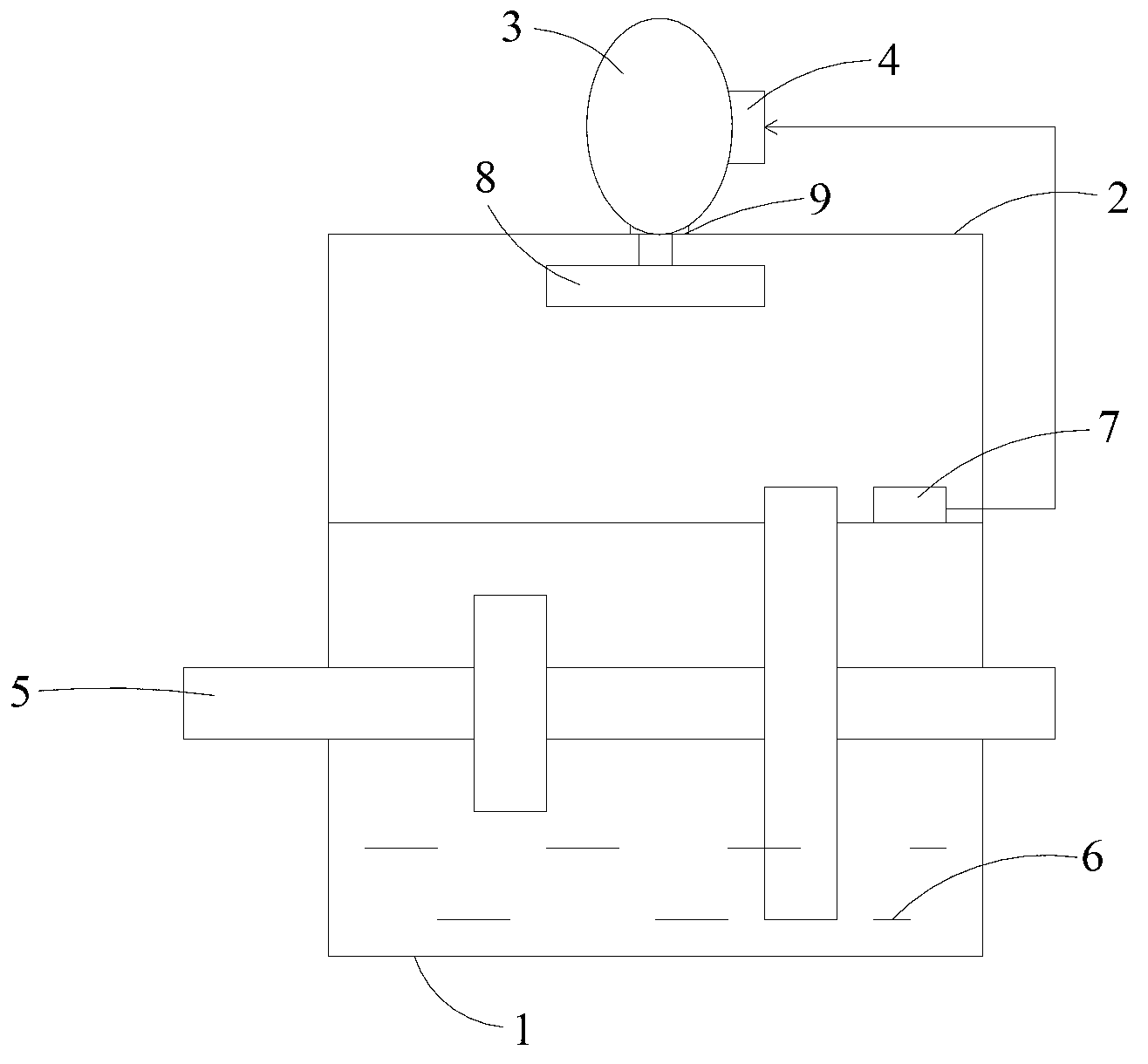

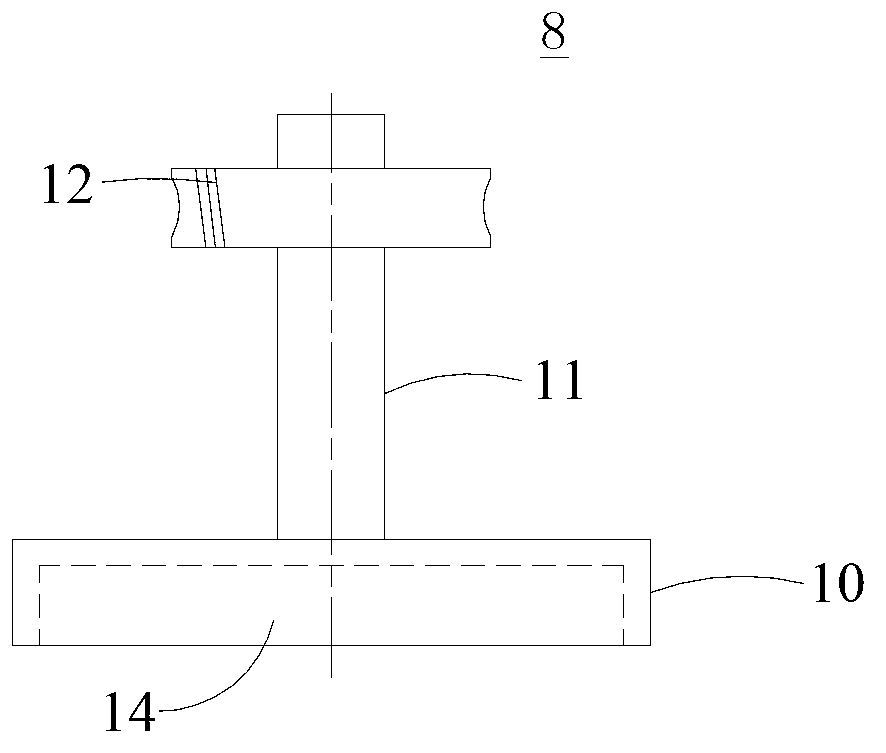

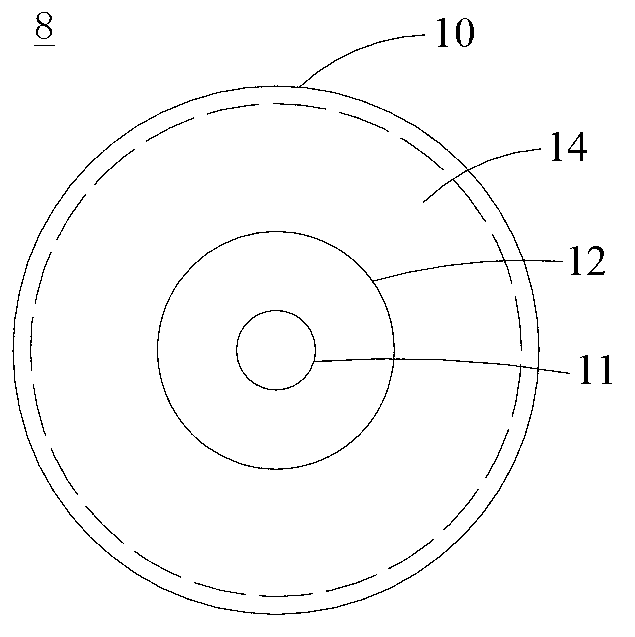

[0024] Such as figure 1 As shown, the gearbox low-pressure anti-leakage device of the present invention includes: a gearbox housing 1, a transmission shaft system 5 arranged in the housing 1, and a lubricating medium 6 accommodated in the housing 1 for lubricating the transmission shaft system 5 The vacuum pump 3 and the control system 4 arranged on the casing 1 are located on the inner wall of the casing 1 for detecting the pressure sensor 7 of the air pressure in the casing 1, and are arranged near the exhaust hole 9 of the top plate 2 of the casing 1 Rotating disc 8 of porous material.

[0025] The vacuum pump 3 can be fixed on the outer wall surface of the top plate 2 of the gearbox housing 1 by welding or screwing. When the gearbox is running, when the pressure in the gearbox casing 1 is greater than the upper limit of the working pressure of the vacuum pump p ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com