Tap converter

A conversion device and tap changer technology, applied in the direction of transformers, electrical components, variable inductors, etc., can solve the problems such as the limitation of the width and size of the transformer box, the deformation of the transformer box, and the assembly and adjustment taking a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiment 1

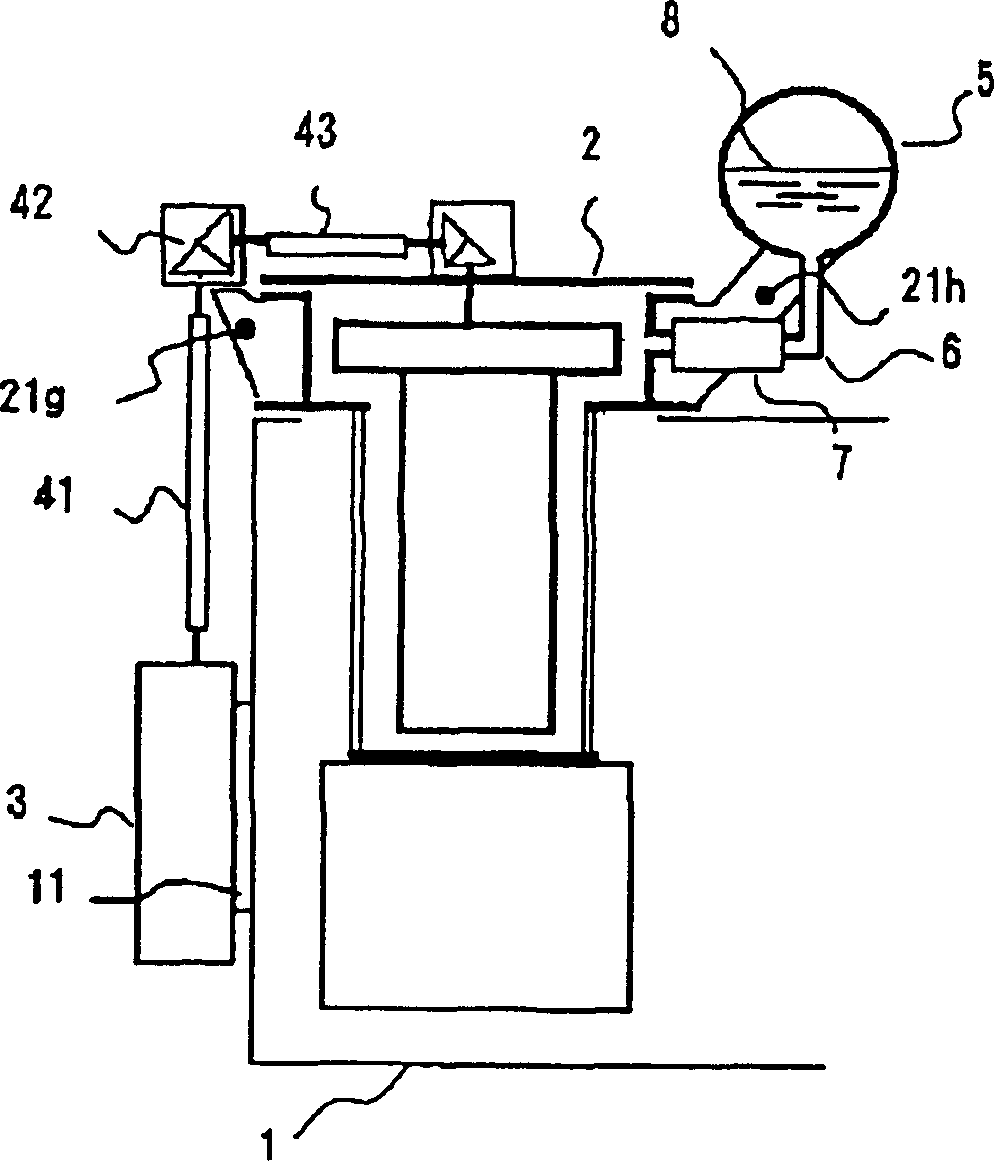

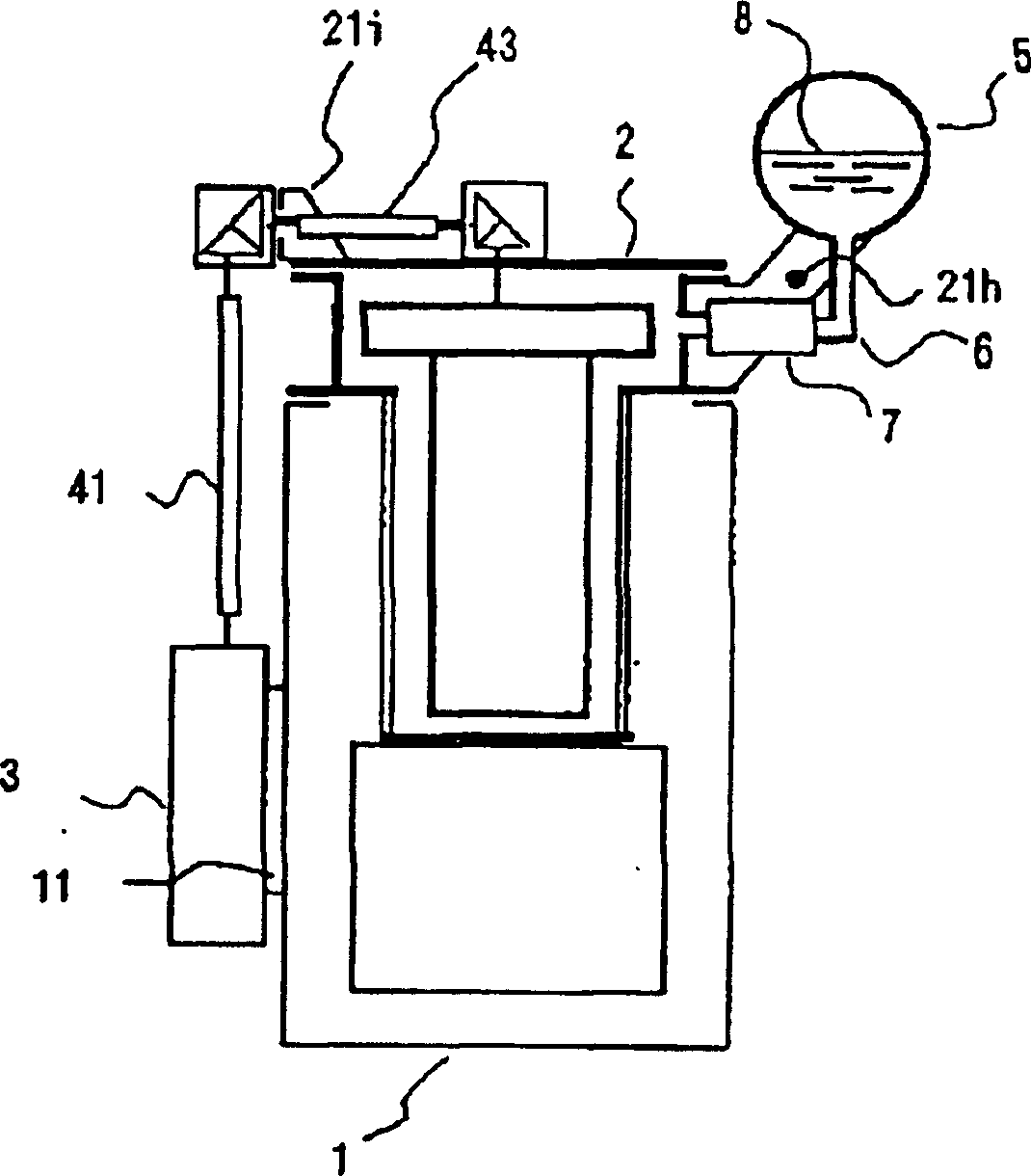

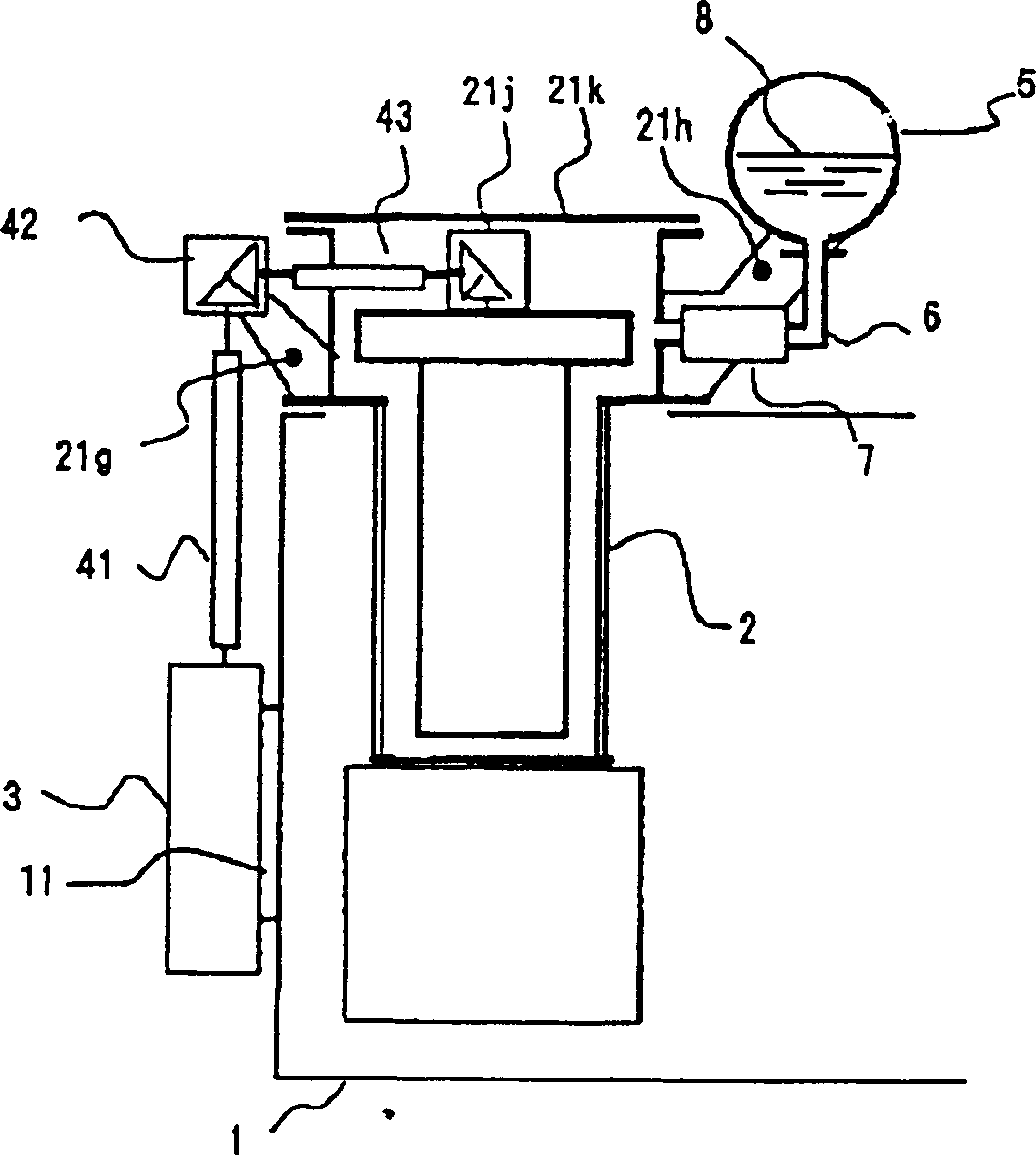

[0042] figure 1 It is a cross-sectional view showing a tap changing device according to Embodiment 1 of the present invention. figure 1 Here, the description of the same symbols as in the conventional example is omitted. 21g is the attachment B of the present embodiment that supports the first direction changing device provided on the head housing 21a of the tap changer 2. 21h is the attachment C of the present embodiment that supports the oil reservoir 5 provided on the head housing 21a of the tap changer 2.

[0043]The operation of the tap changing device configured as described above is the same as the aforementioned conventional example, but the assembly sequence of the structural elements of the tap changing device is different as described below.

[0044] (1) First, prepare in advance the transformer box 1 in the state where the mounting member A of 9 is fixed at a predetermined position of the transformer box 1 by, for example, welding;

[0045] (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com