Device for drilling hole in flange on valve

A technology for flanges and valves, which is applied in positioning devices, driving devices, feeding devices, etc. It can solve the problems of flange edges bending downwards, not being able to adapt to valves, and affecting processing accuracy, so as to ensure smoothness and processing effects Good, high processing precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

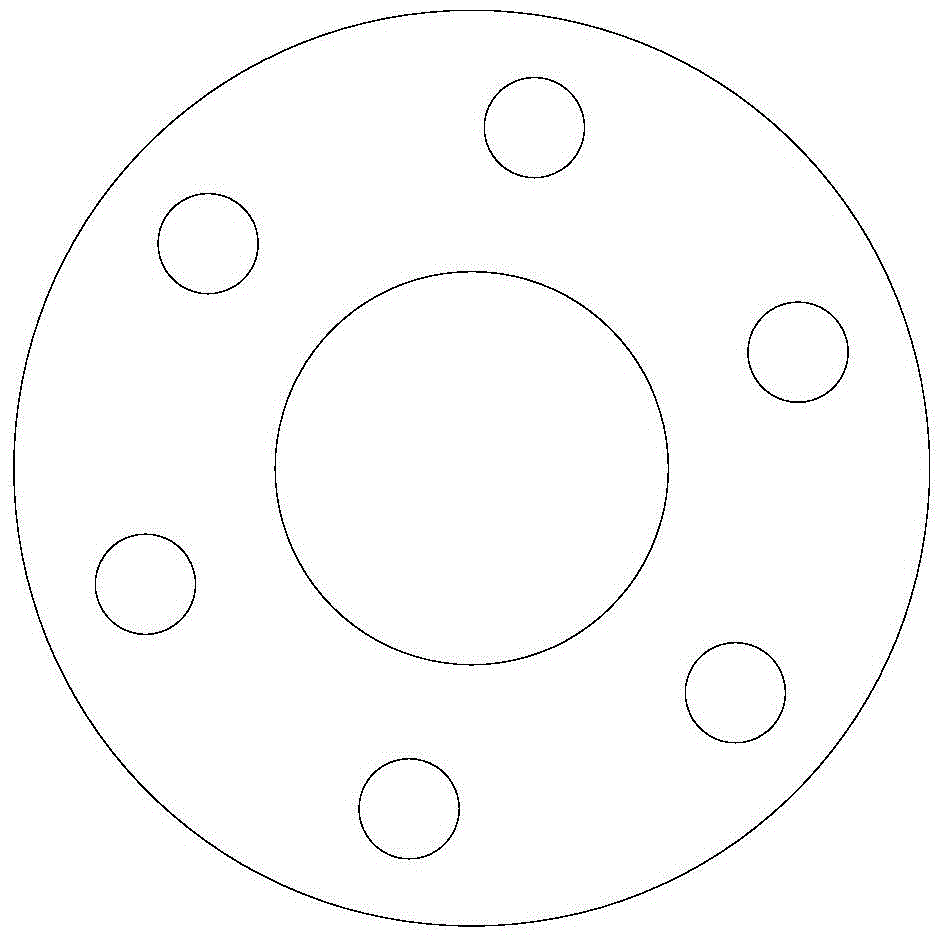

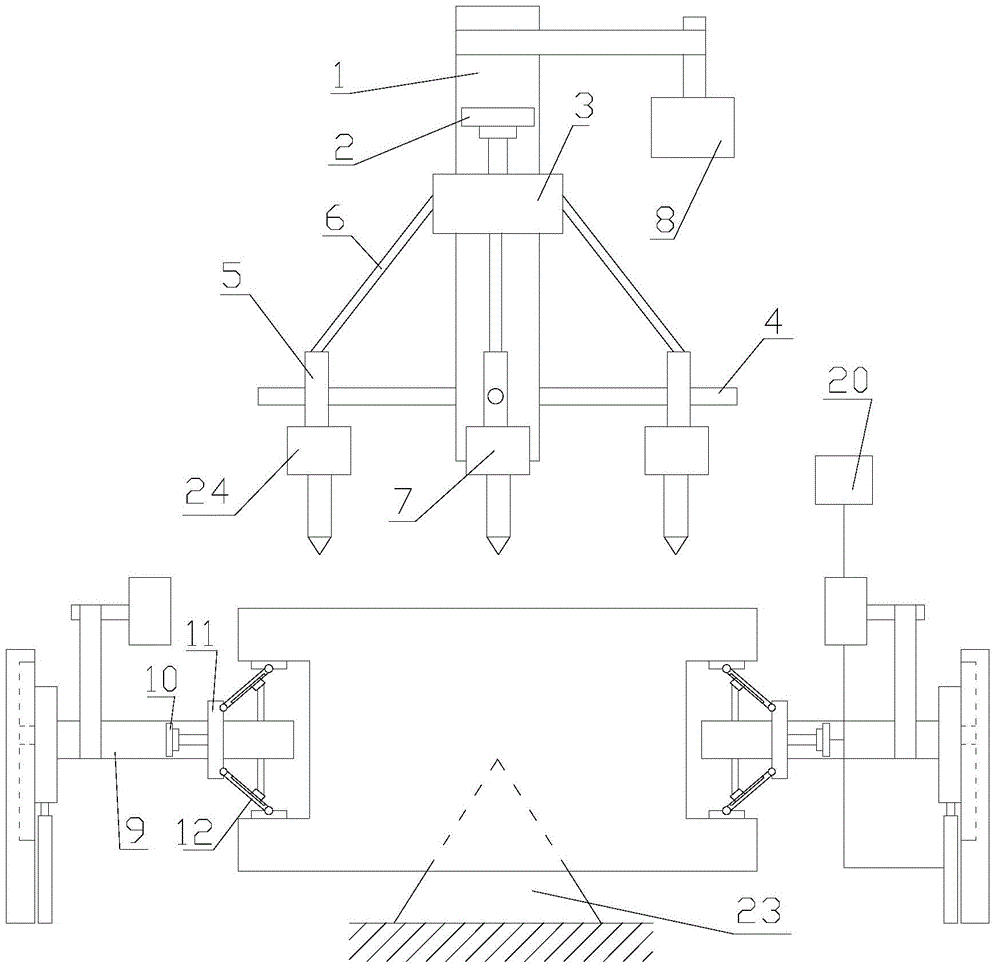

[0034] refer to figure 1 , 2 , 3, 4:

[0035] A device for drilling a flange on a valve proposed by the present invention includes a drilling mechanism for drilling the flange and a clamping mechanism for clamping the valve;

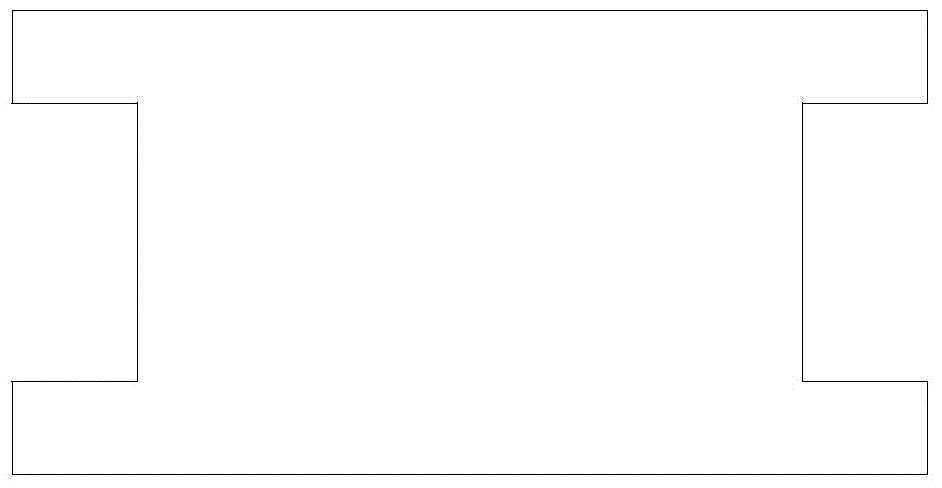

[0036] The drilling mechanism includes a pillar 1 and a hydraulic cylinder 2. The pillar 1 is distributed along the axial direction of the flange. The pillar 1 is provided with a first collar 3 and N slide rods 4, where N is 1, 2, 3, 4 , 5 or 6, the slide bar 4 is distributed around the center of the pillar 1, and the slide bar 4 is arranged parallel to the surface of the flange. When N≠1, the angle between adjacent slide bars 4 is 60 degrees or 180 degrees; N=1 in the present embodiment, the included angle between adjacent slide bar 4 is 60 degree; All be provided with drilling unit on each slide bar 4, this drilling unit passes slide block 5 and slide bar 4 Sliding connection; the first collar 3 is hinged to the sliding block 5 through an equal-leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com