Ultra-dry filtering machine and filtrating method thereof

A filtration method and filter technology, applied in the directions of filtration and separation, separation methods, chemical instruments and methods, can solve the problems of low degree of automation, affecting the strength of the cylinder body, low work efficiency, etc., to improve the level of automation and improve desliming. Effects, effects with a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

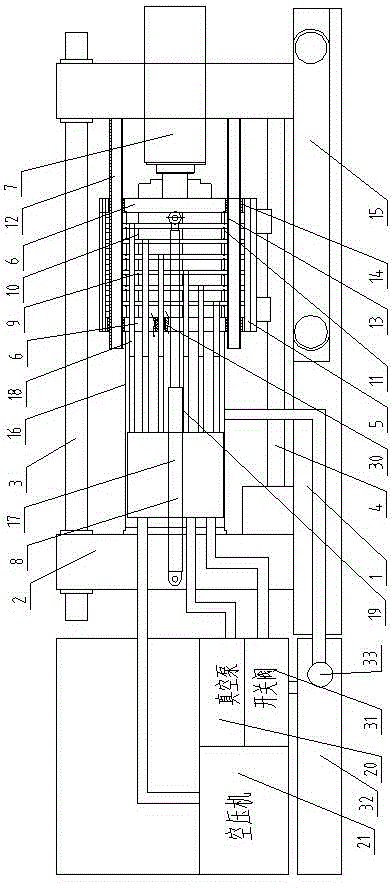

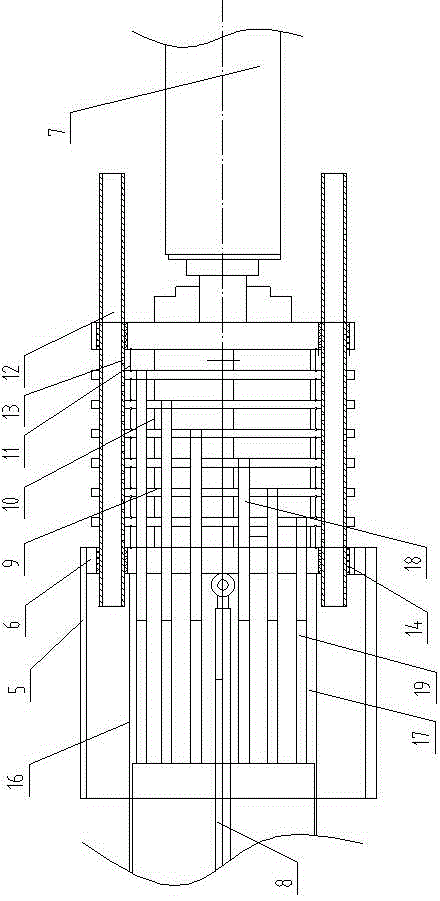

[0031] Such as figure 1 , 2 , 3, the present invention includes a bed 1, the left and right sides of the bed 1 are respectively provided with walls 2, the walls 2 on both sides are connected by pull rods 3, and the bed 1 is provided with horizontally arranged slides. Rail 4, the top of slide rail 4 is provided with cylinder body 5, and the bottom of cylinder body 5 is slidably installed on the slide rail 4 by slide block, and the below of cylinder body 5 is provided with belt conveyor 15.

[0032] Pistons 6 are respectively arranged on the left and right sides of the cylinder body 5, and the piston 6 on the left side is connected to the wall body 2 on the left side through a hollow cantilever 16. A sealed transfer box 17 is fixed in the cavity of the cantilever 16, and the cylinder body 5 The wall body 2 on the right side is connected with the first hydraulic cylinder 7, the piston 6 on the right side is connected with the hydraulic rod of the first hydraulic cylinder 7, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com