Hierarchical multi-grade type concrete mortar preparation material mixing treatment technology

A concrete mortar, layered and multi-stage technology, applied in the direction of clay preparation equipment, grain treatment, pretreatment control, etc., can solve the problems of additives and moisture residue, excessive water injection, affecting concrete strength and viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

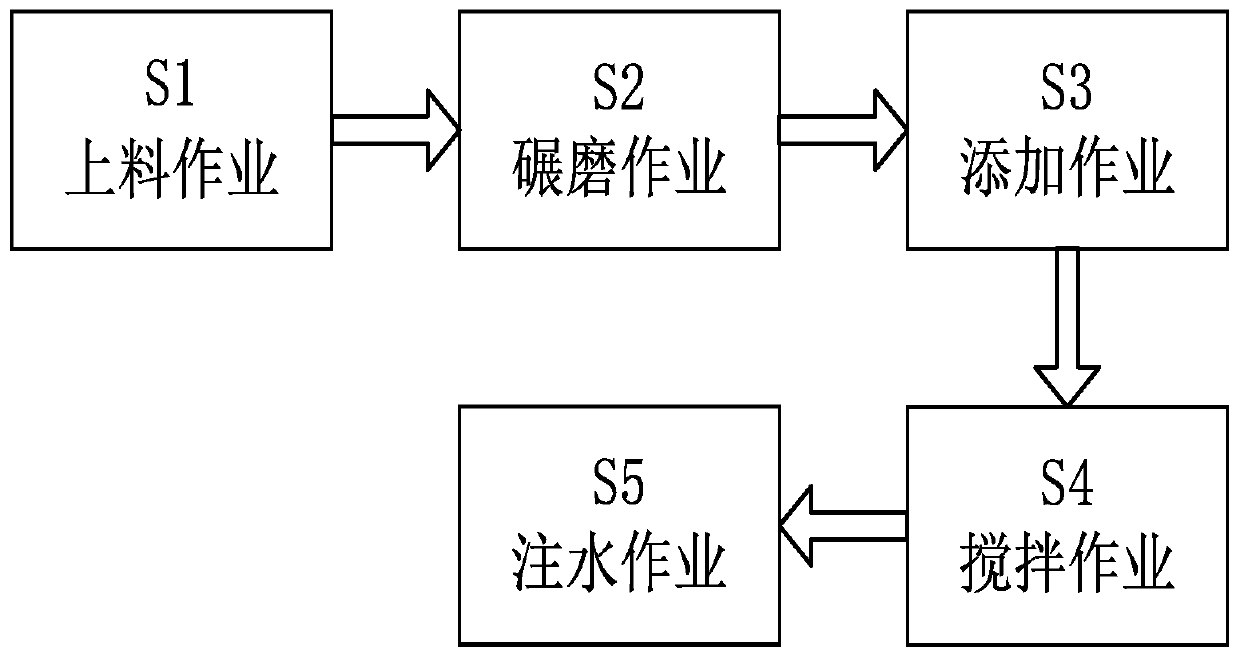

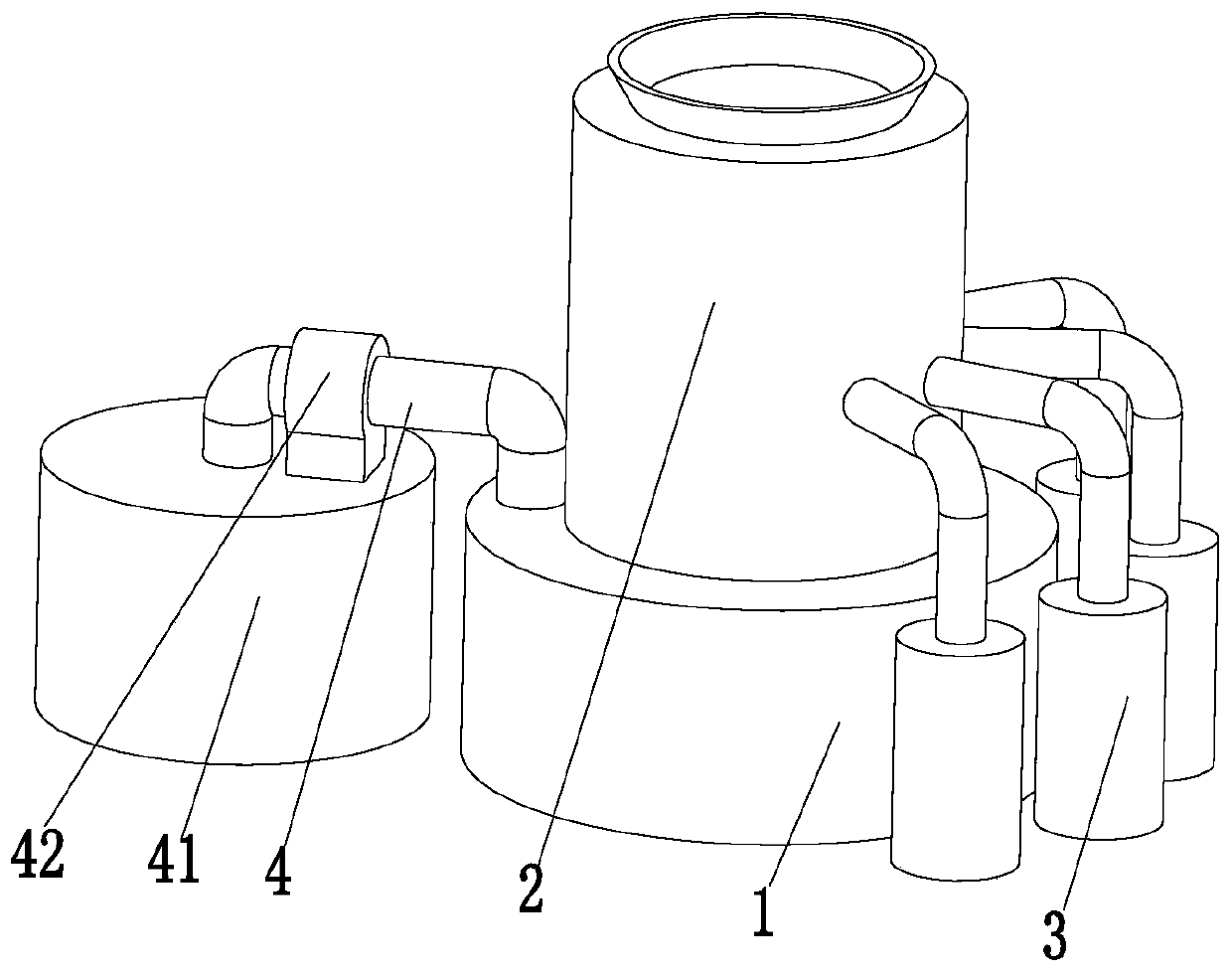

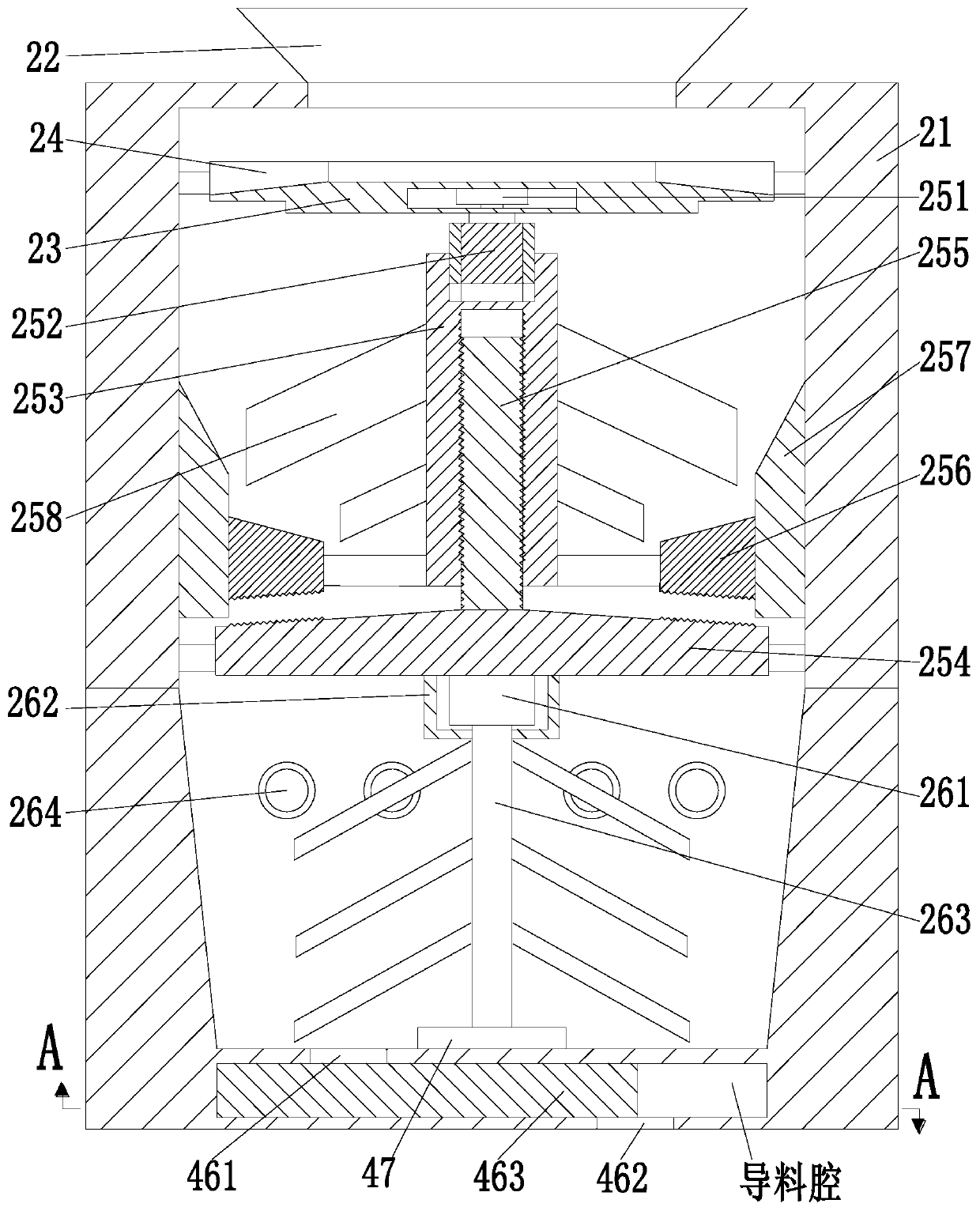

[0030] Such as Figure 1 to Figure 5 As shown, a layered multi-stage concrete mortar preparation and mixing process uses a concrete mortar preparation device, which includes a mixing cylinder 1, a processing unit 2, an additive cylinder 3 and a water injection unit 4 The method for mixing concrete by using the above-mentioned concrete mortar preparation device also includes the following steps:

[0031] S1, feeding operation: import sand and cement from the feeding port 22 into the processing cylinder 21 by manual or mechanical assistance;

[0032] S2. Milling operation: the sandstone and cement introduced into the processing cylinder 21 in the step S1 are stirred and milled by the milling mechanism 25 to form mortar;

[0033] S3. Adding operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com