Patents

Literature

84results about "Volumetric measuring devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

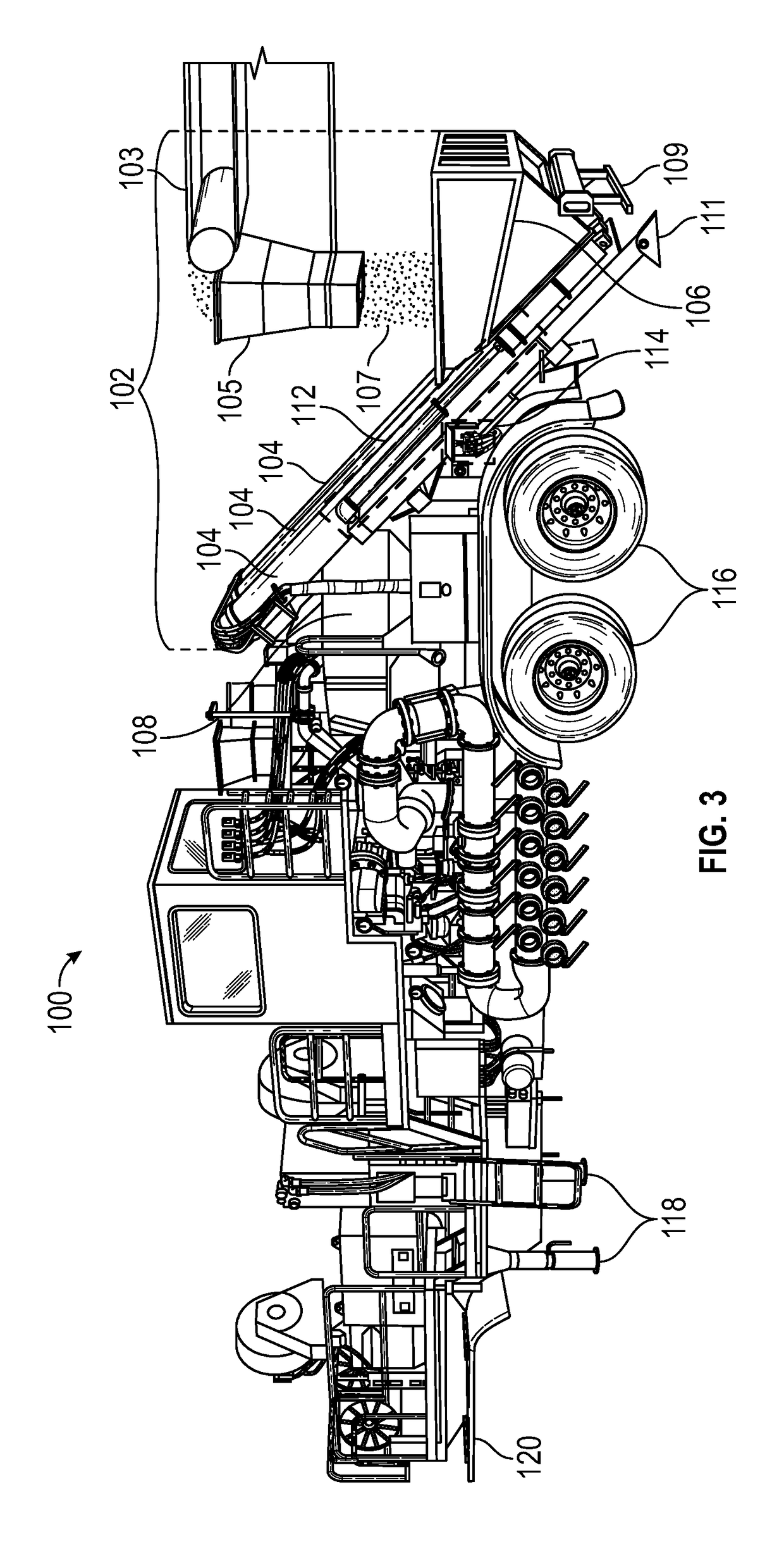

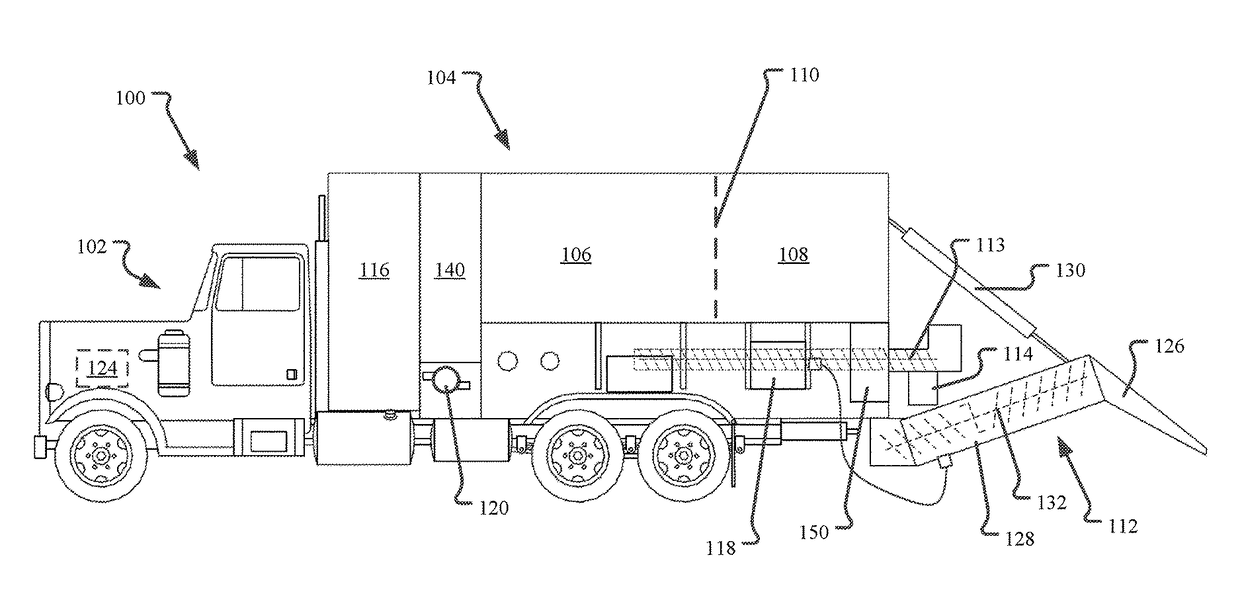

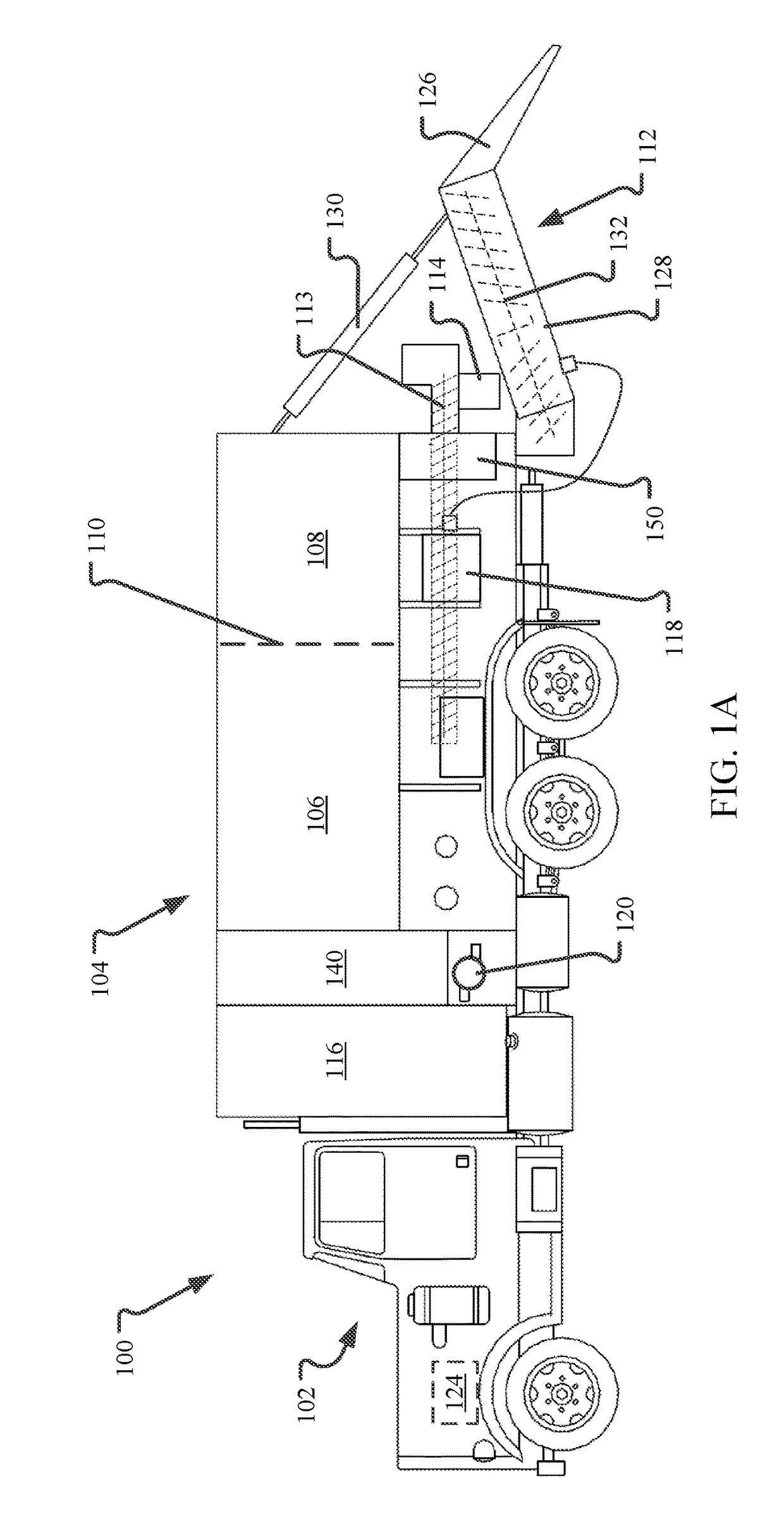

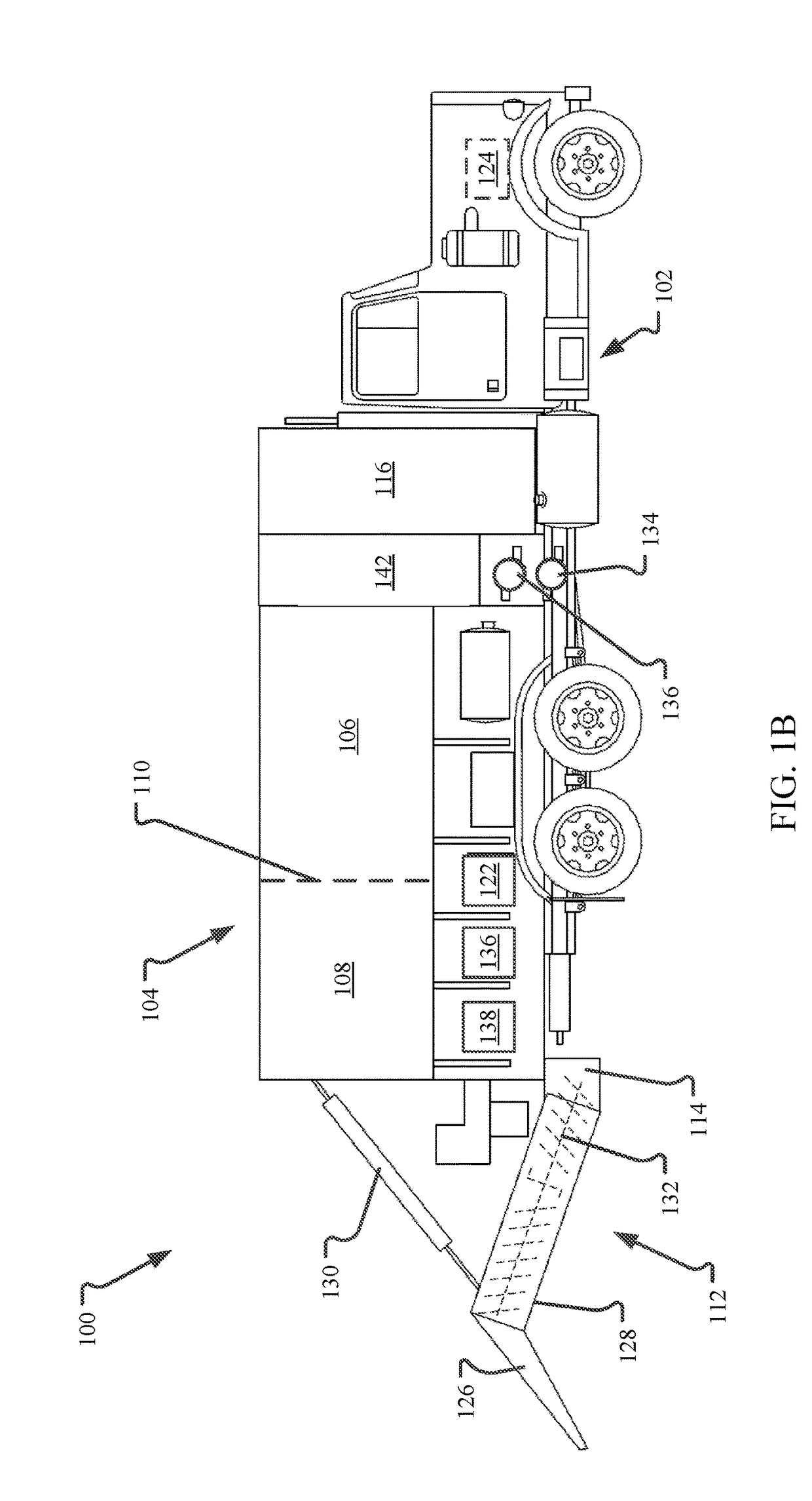

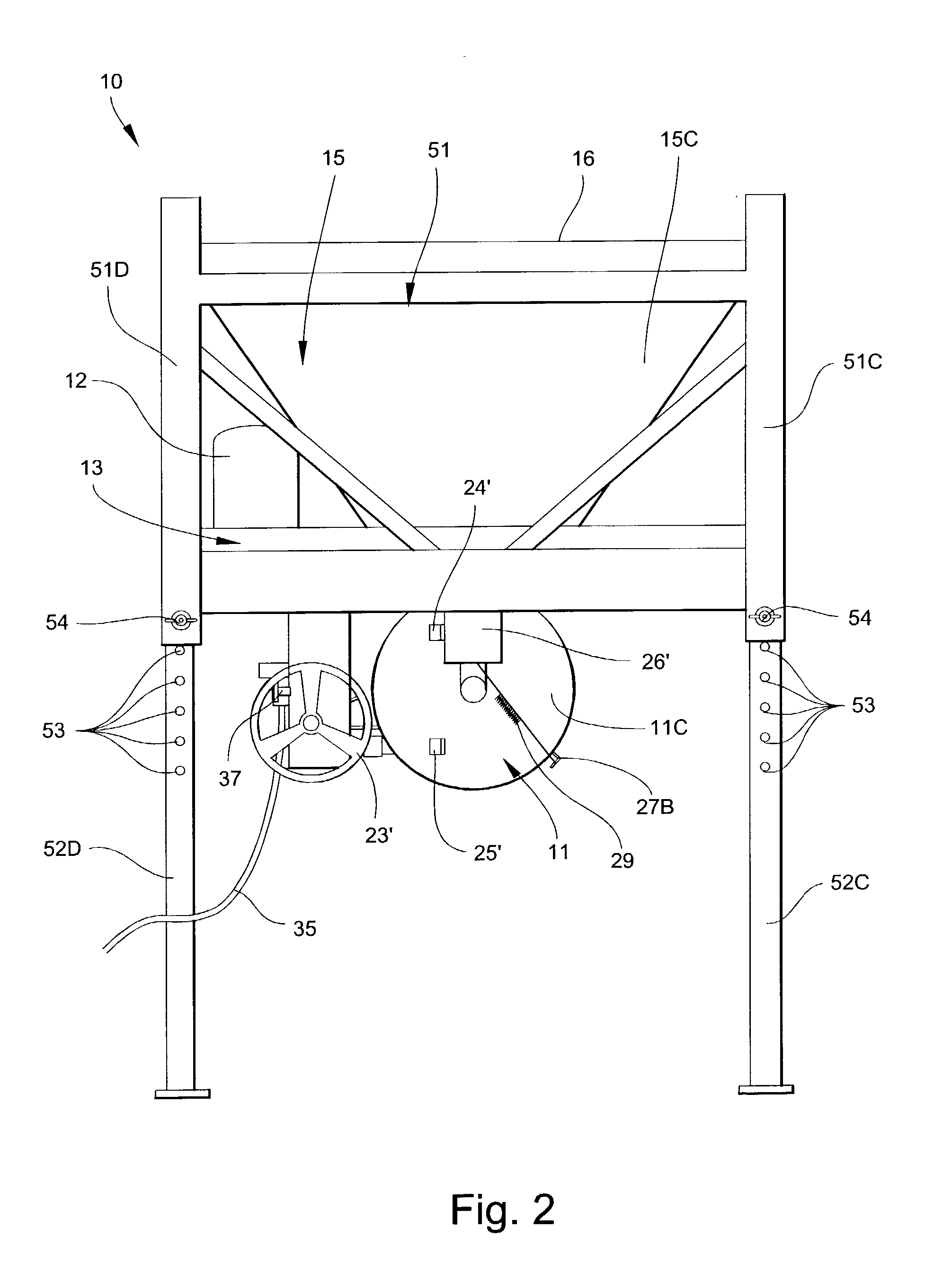

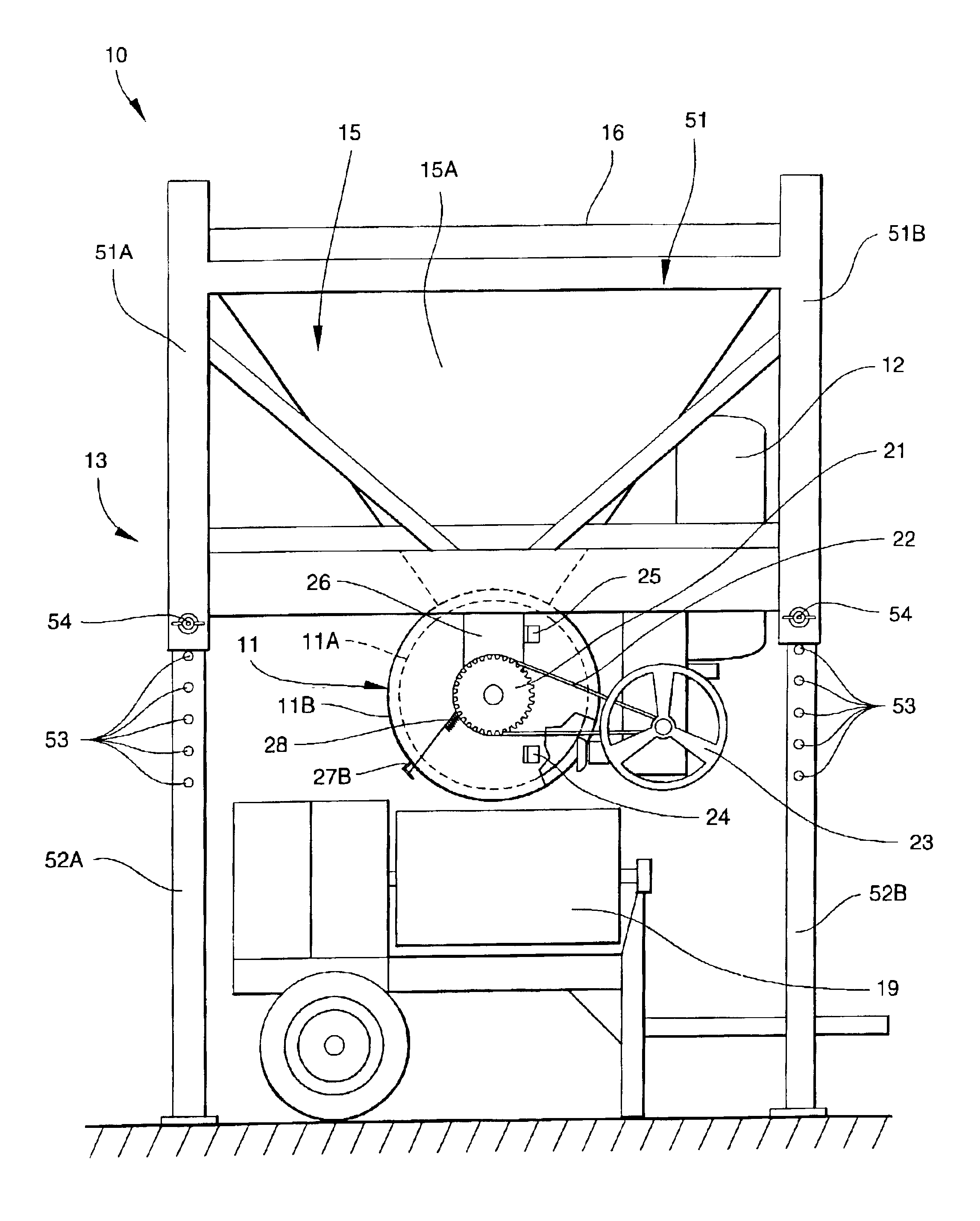

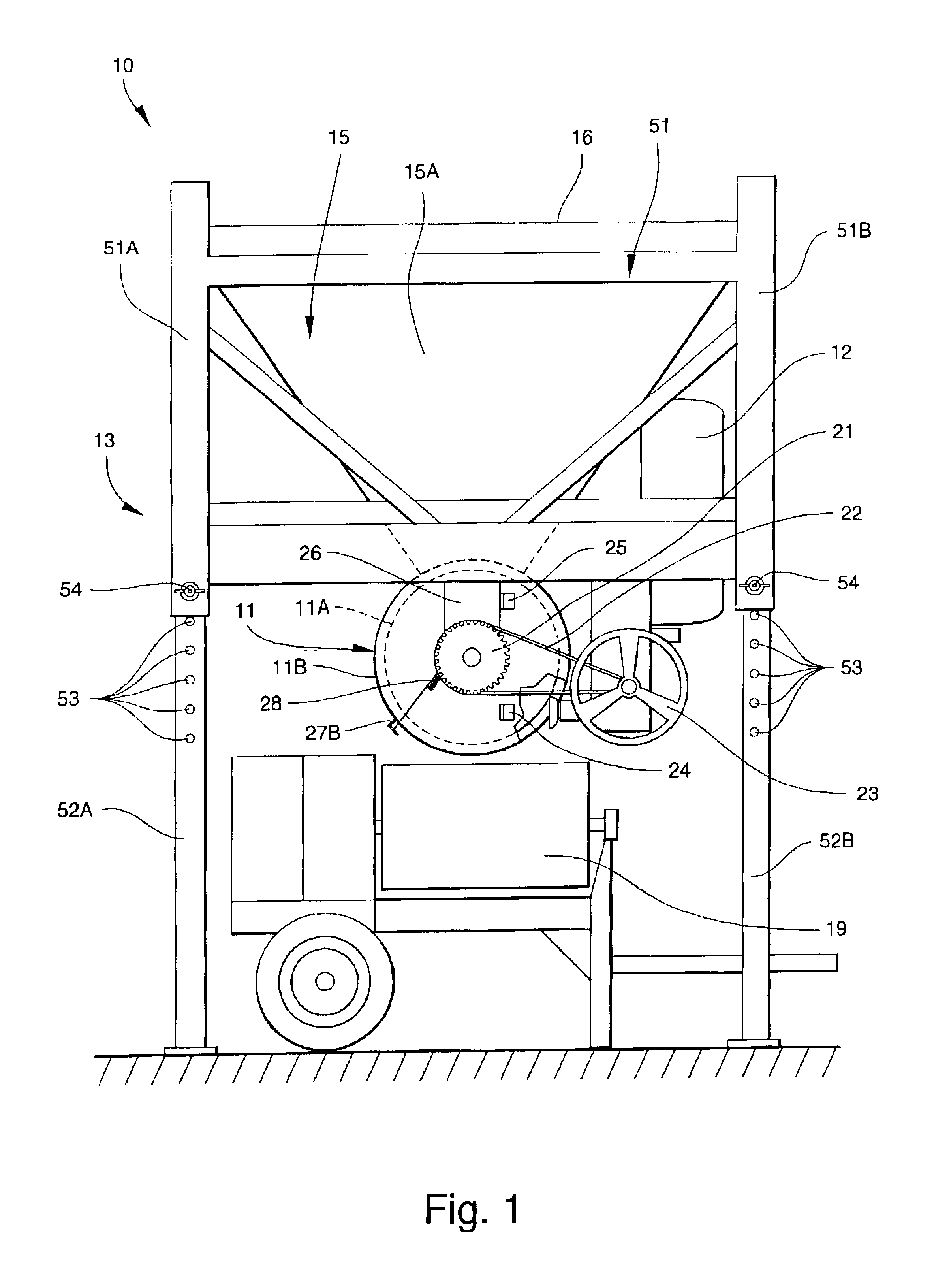

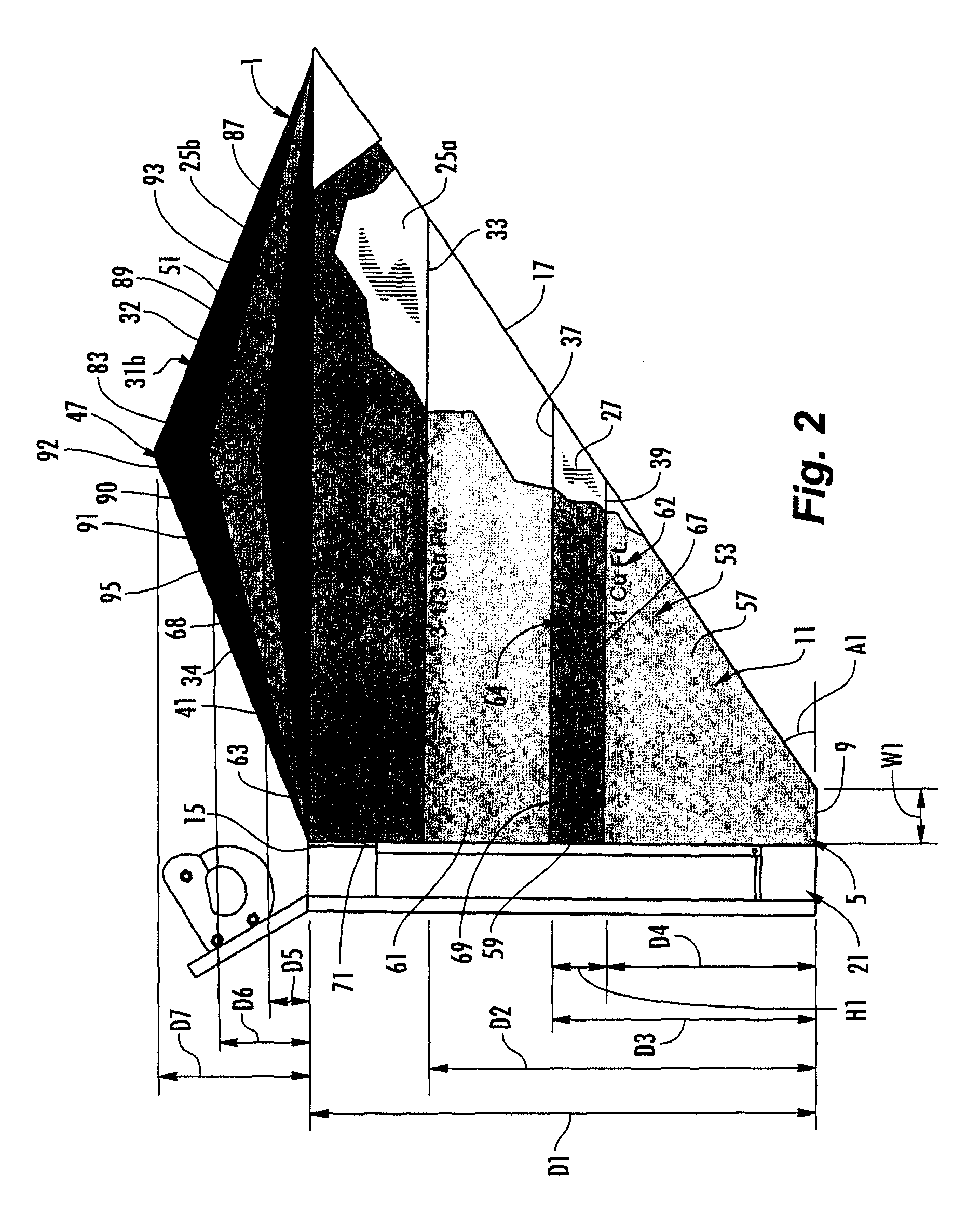

Independent control of auger and hopper assembly in electric blender system

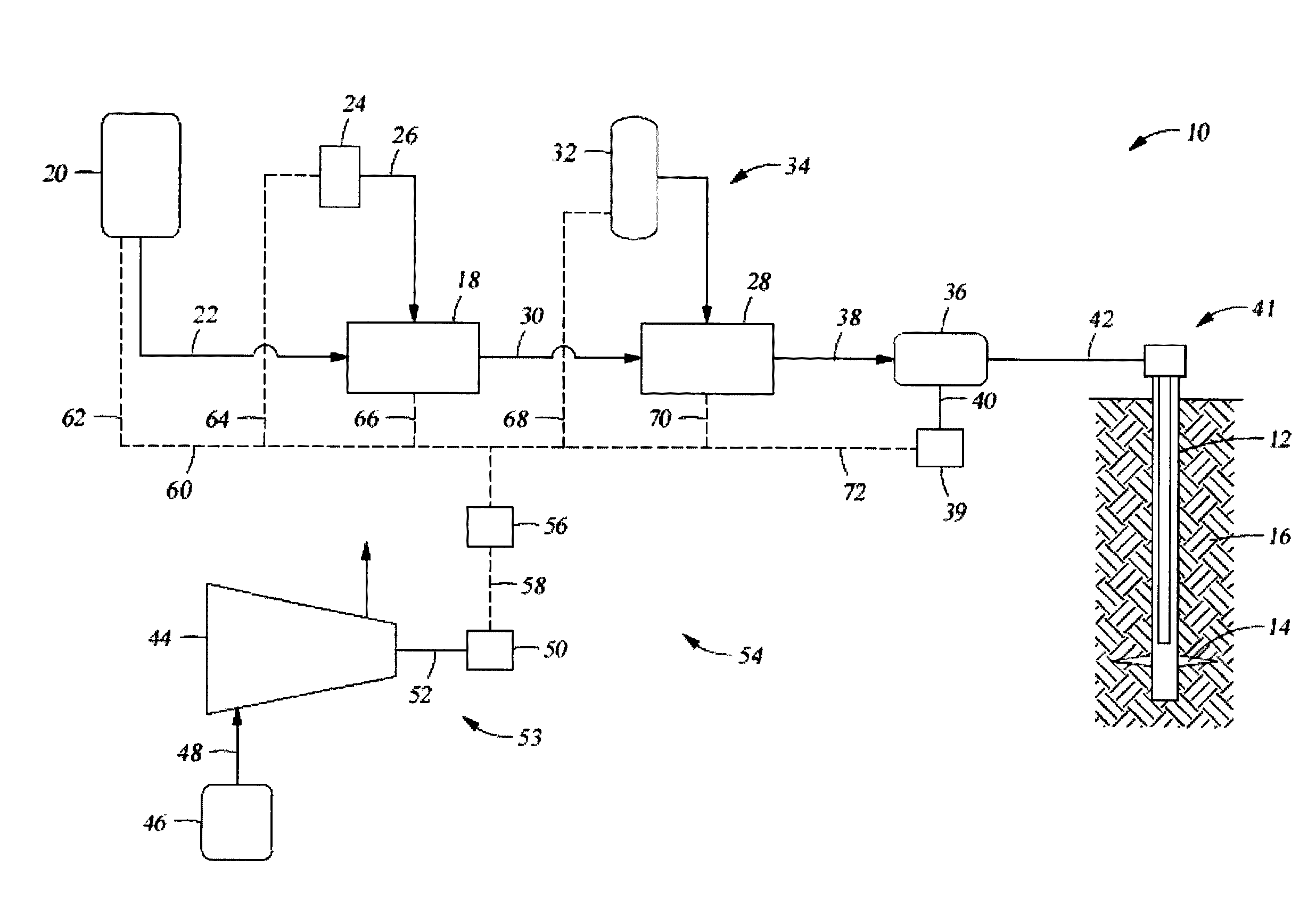

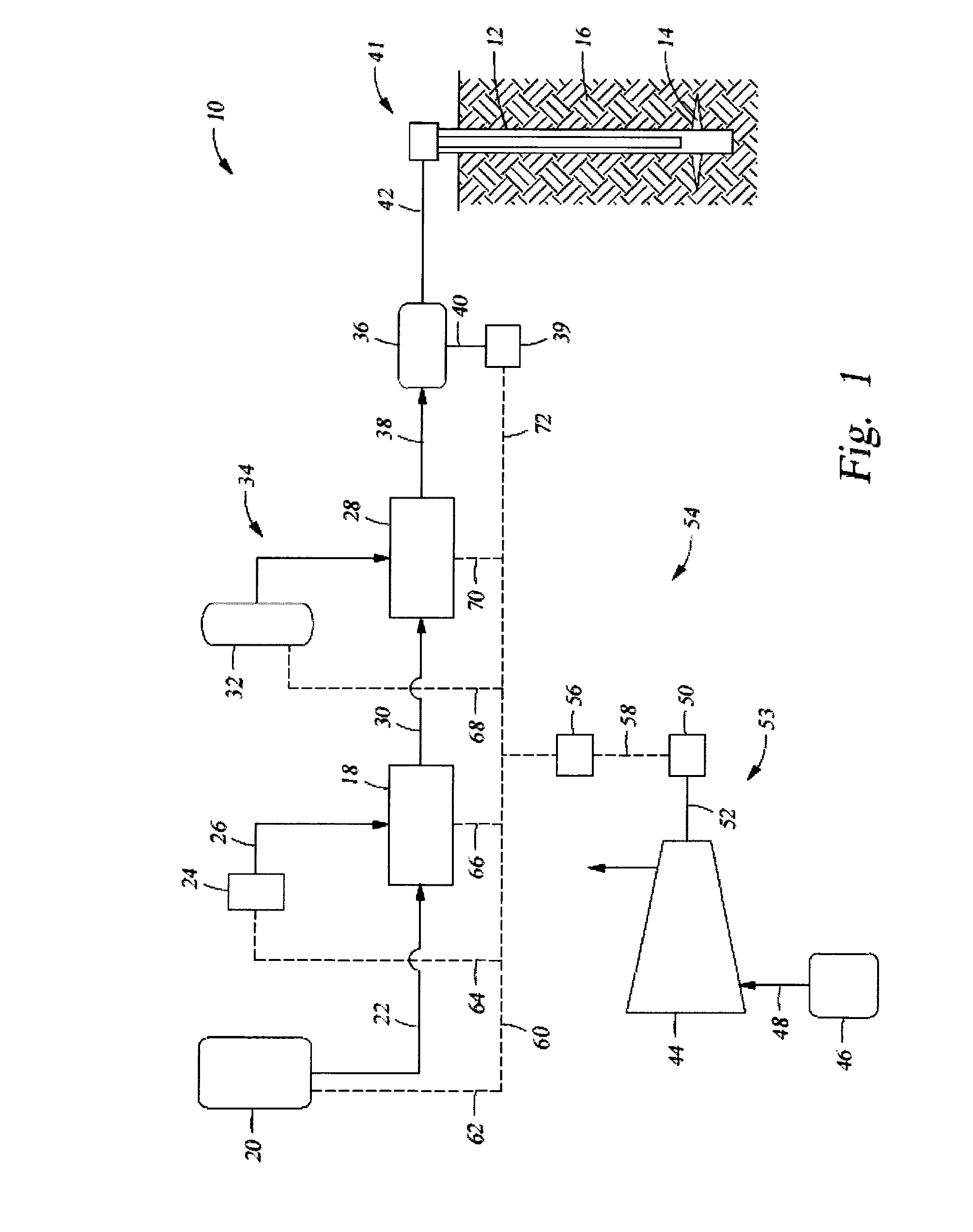

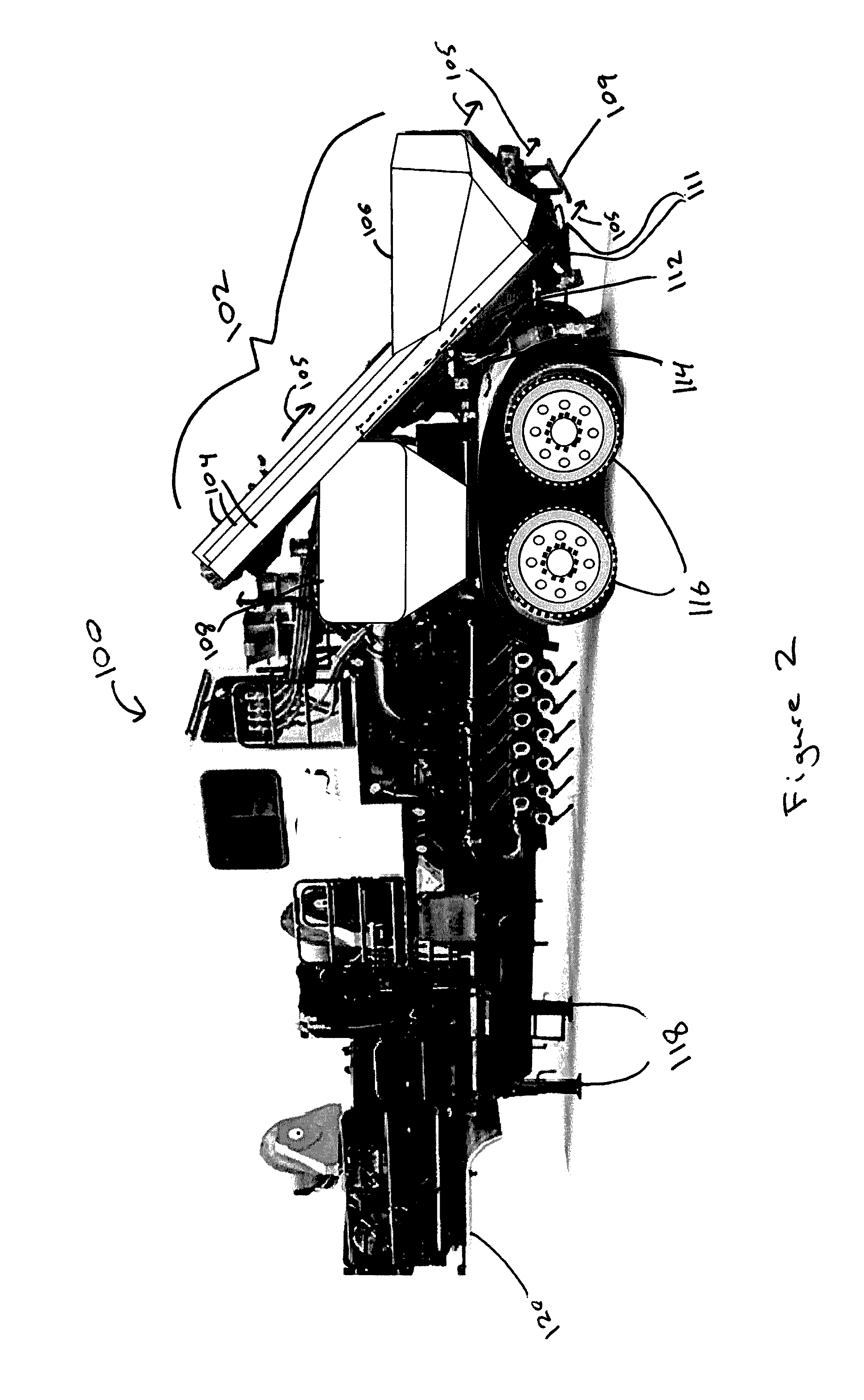

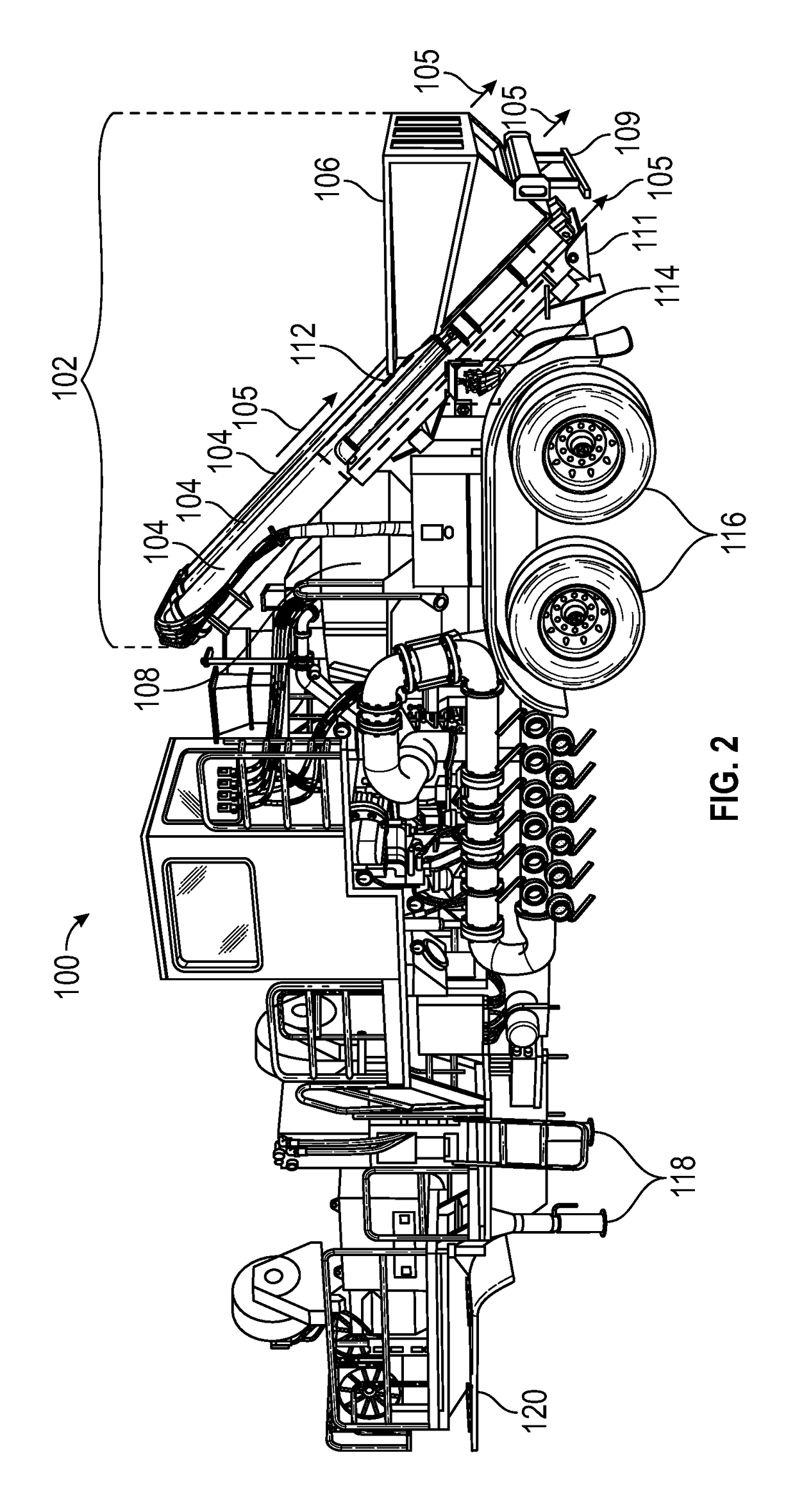

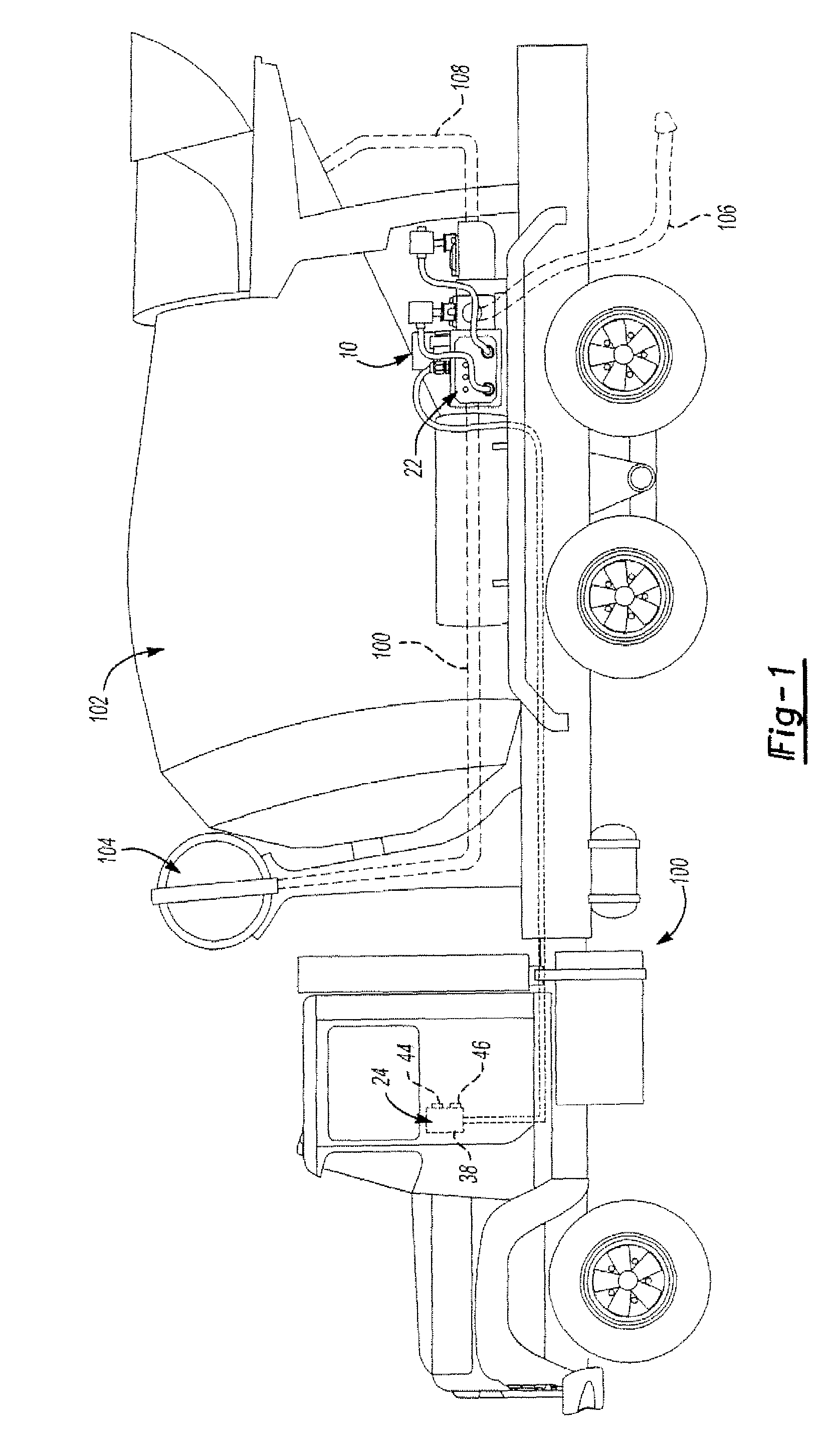

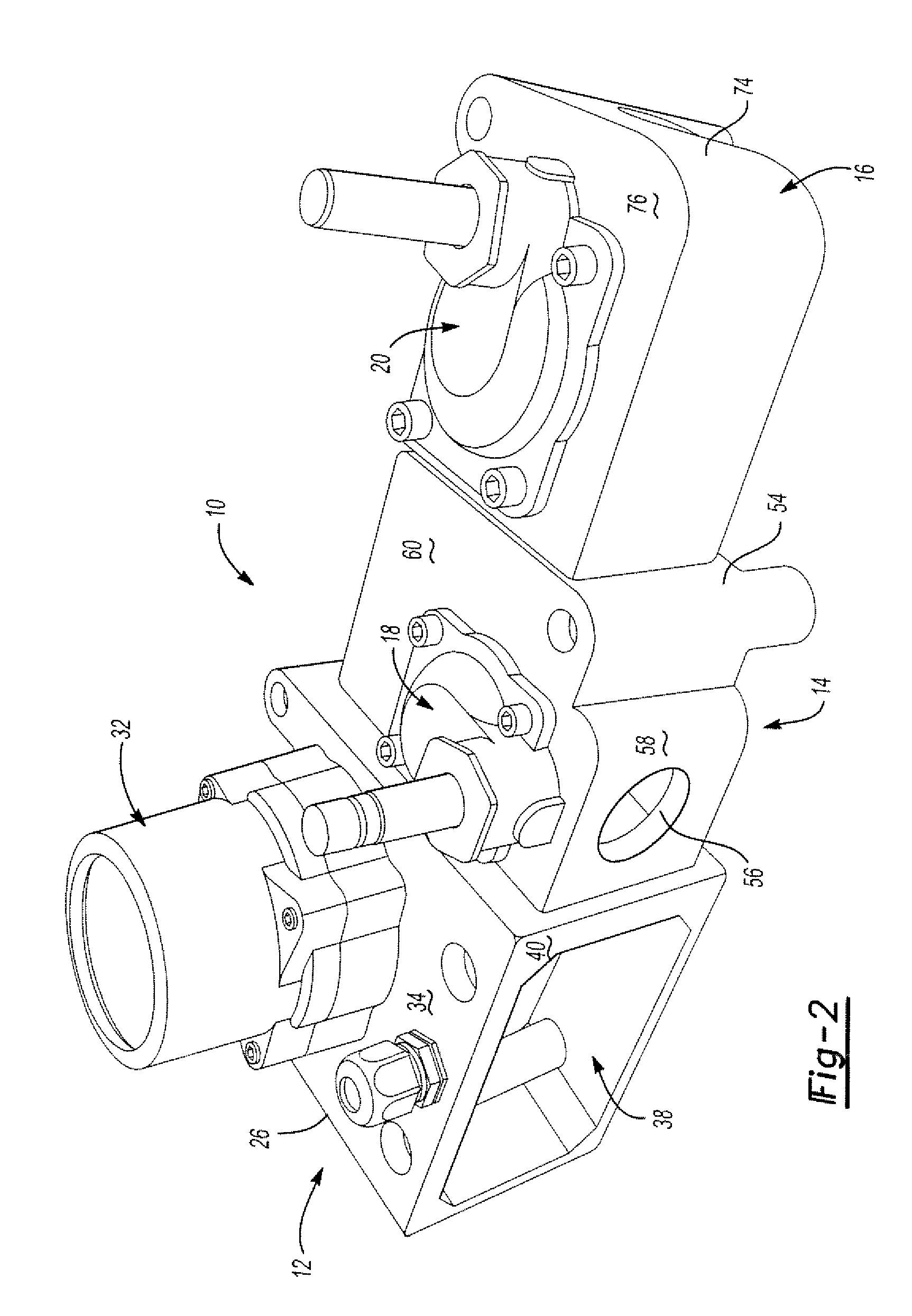

Embodiments relate to a hydraulic fracturing system that includes a blender unit. The system includes an auger and hopper assembly to receive proppant from a proppant source and feed the proppant to the blender unit for mixing with a fluid. A first power source is used to power the blender unit in order to mix the proppant with the fluid and prepare a fracturing slurry. A second power source independently powers the auger and hopper assembly in order to align the hopper of the auger and hopper assembly with a proppant feed from the proppant source. Thus, the auger and hopper assembly can be stowed or deployed without use of the first power source, which is the main power supply to the blender unit.

Owner:US WELL SERVICS LLC

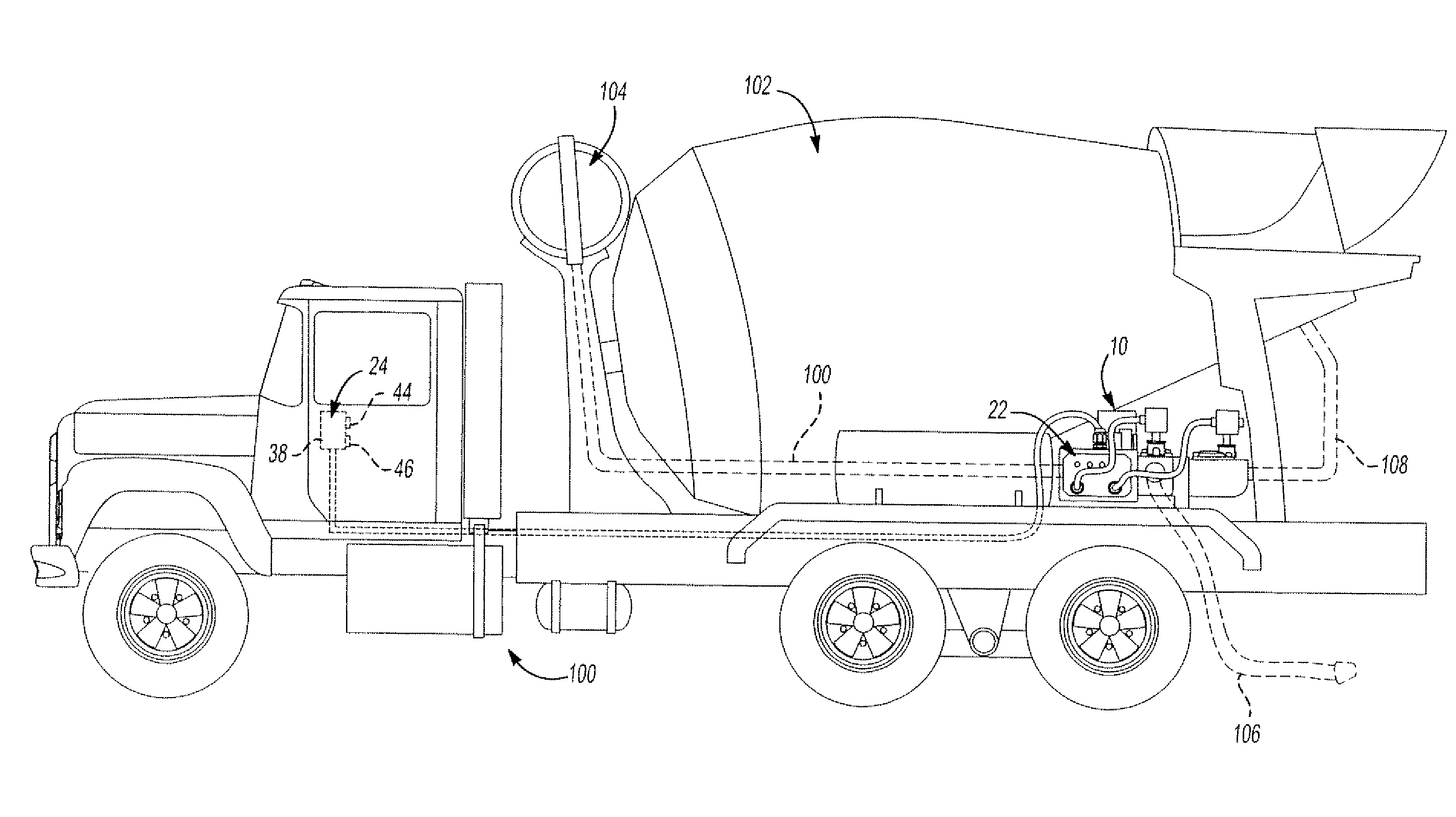

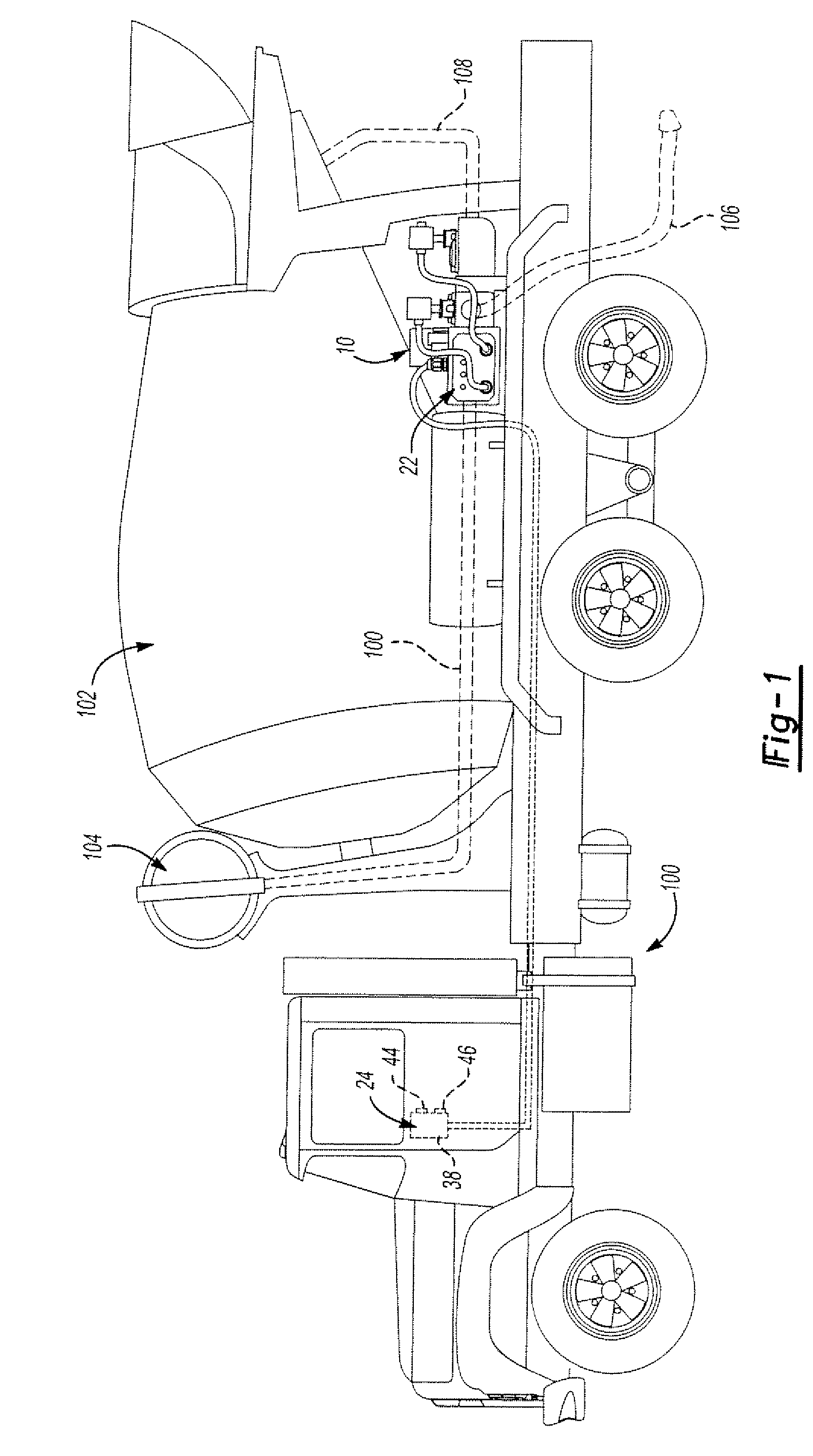

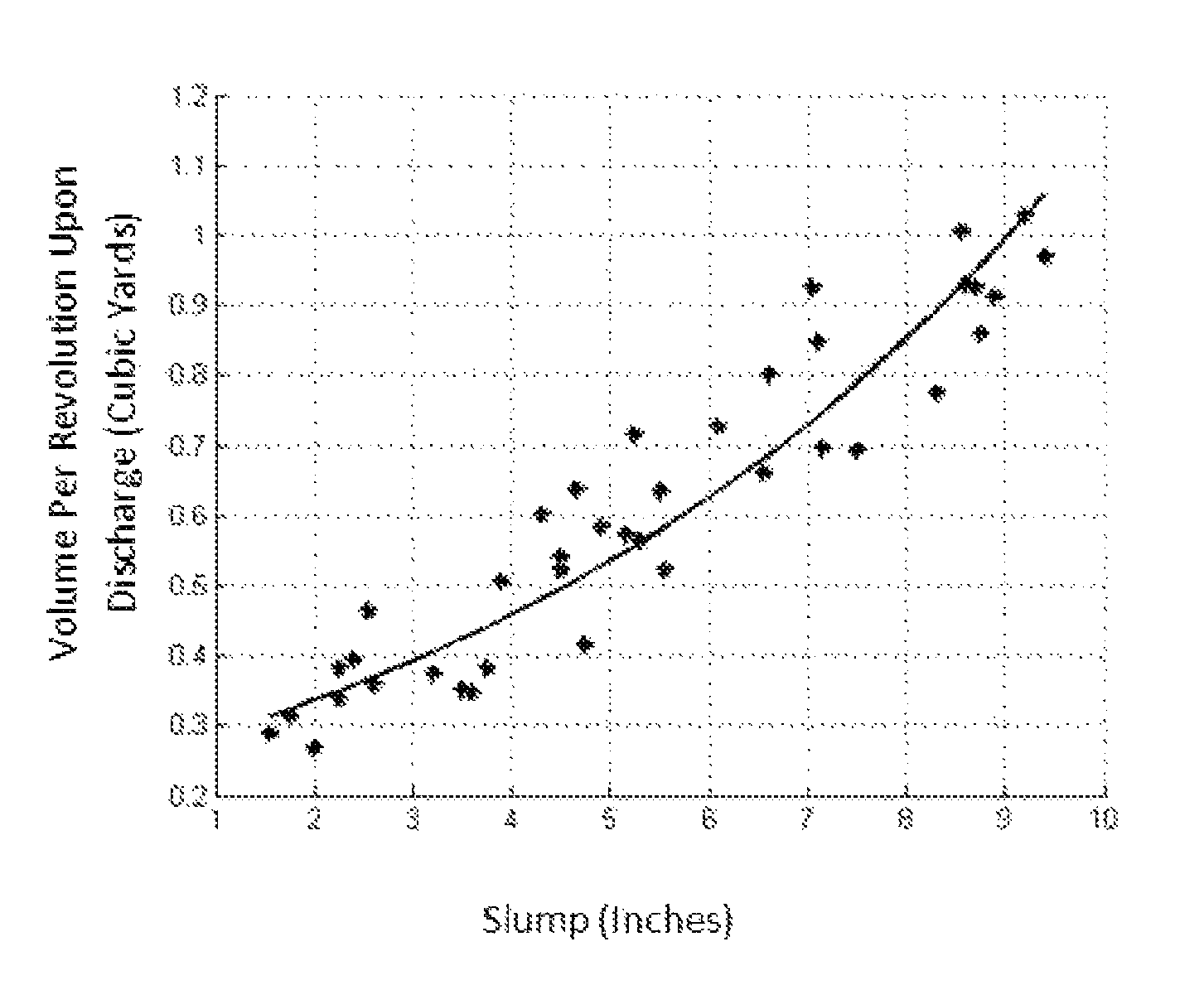

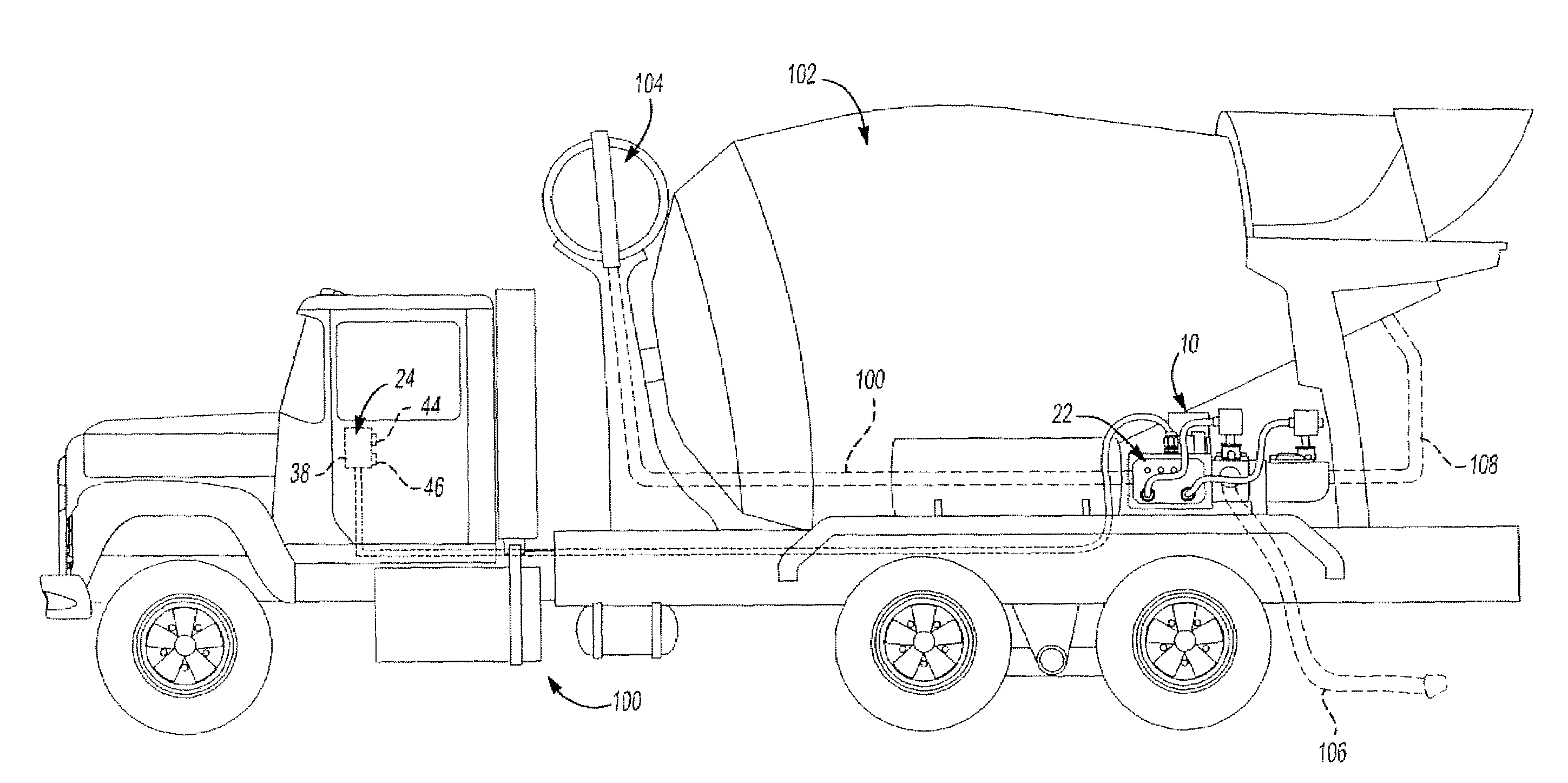

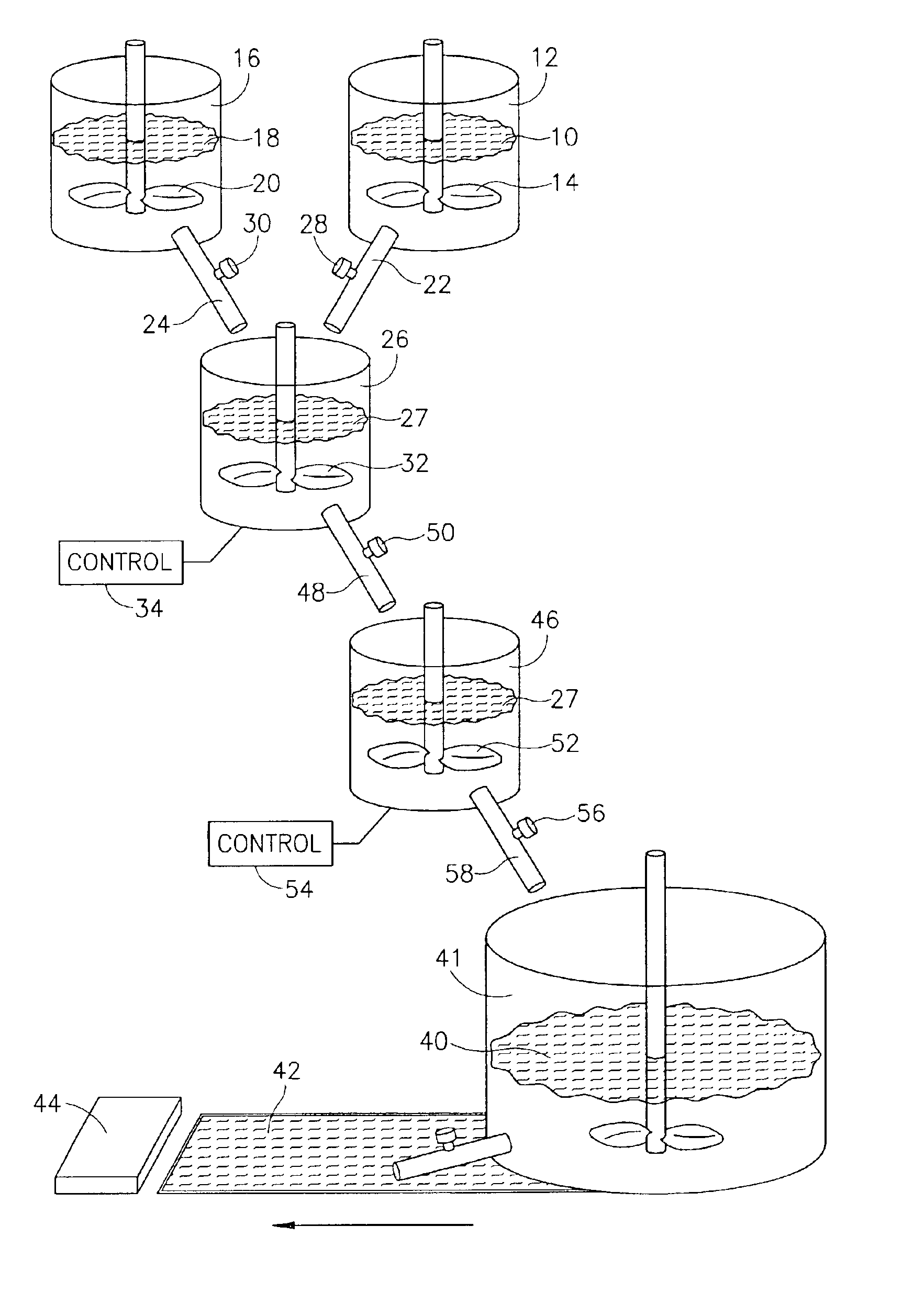

Treating and reporting volume of concrete in delivery vehicle mixing drum

ActiveUS20140104972A1Novel convenient highly accurate methodAccurate and convenient methodSampled-variable control systemsDischarging apparatusDelivery vehicleMonitoring system

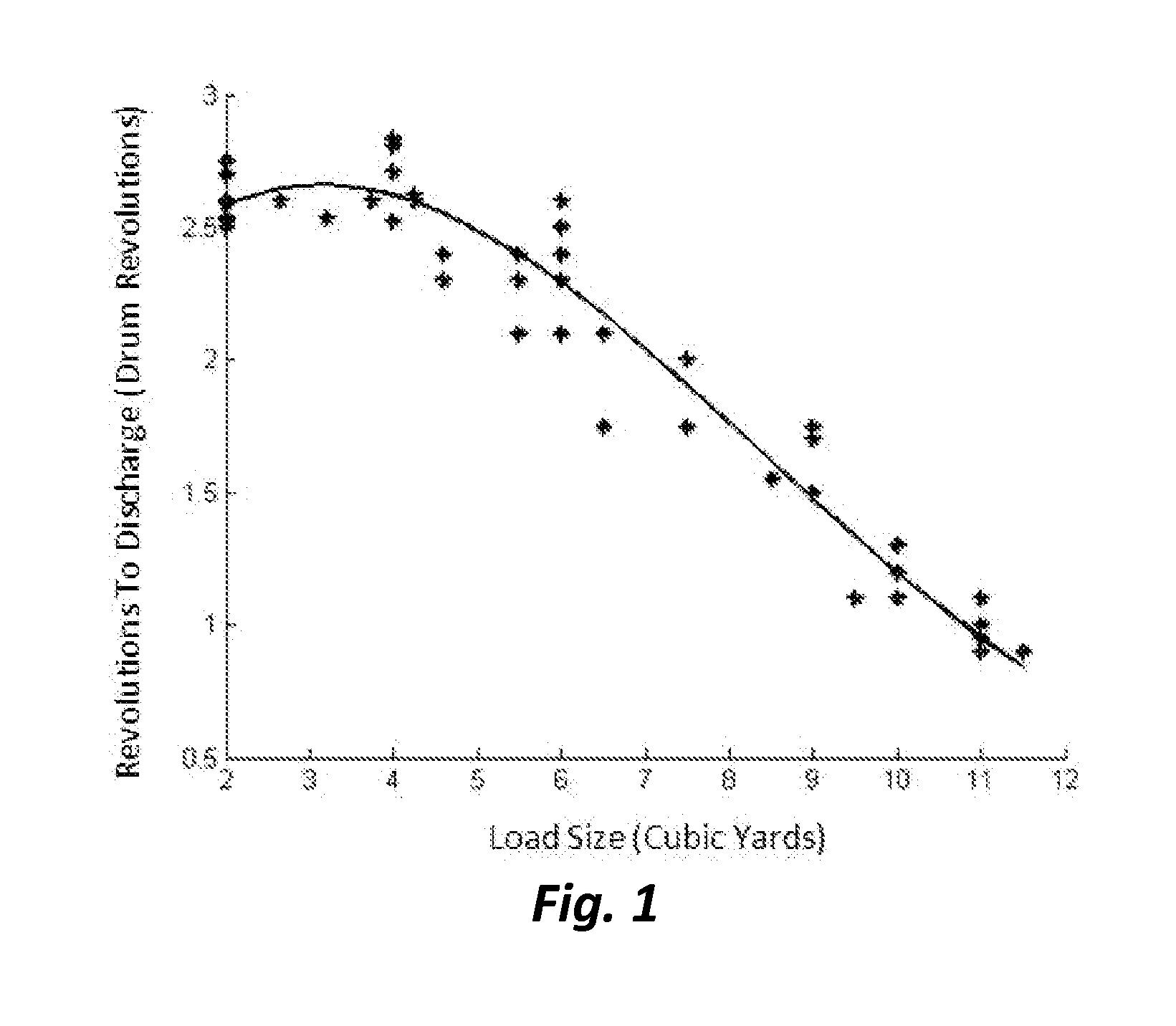

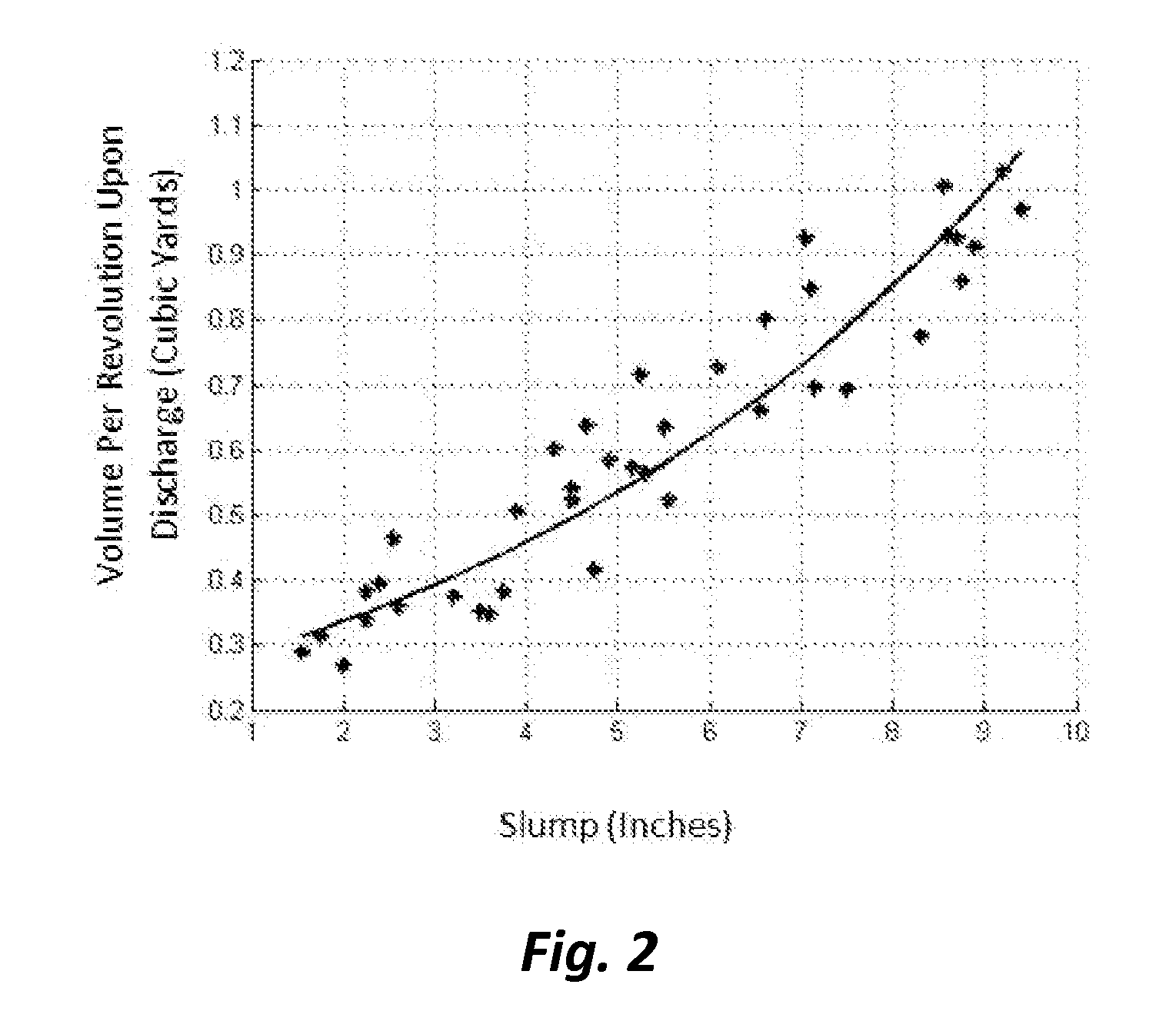

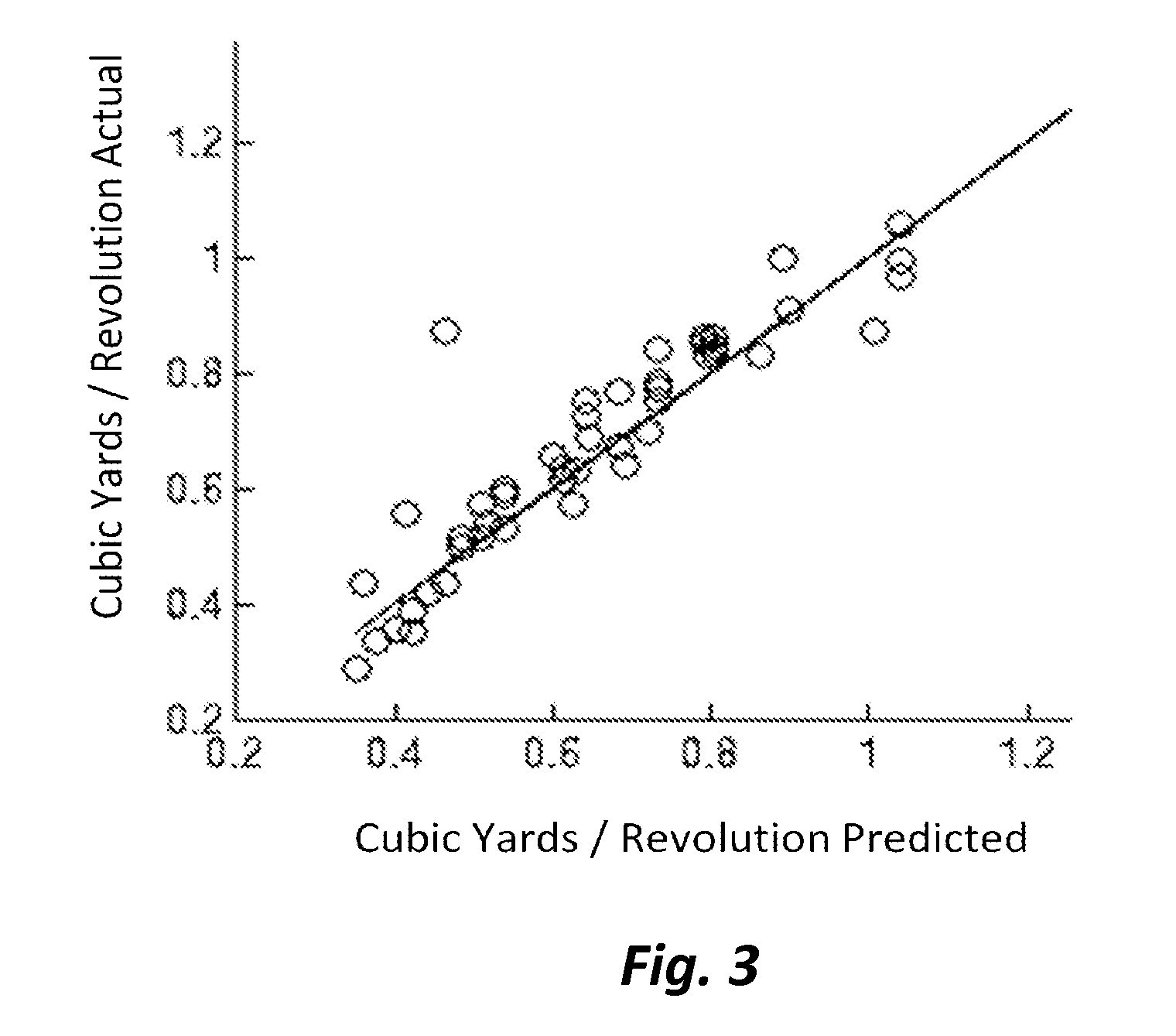

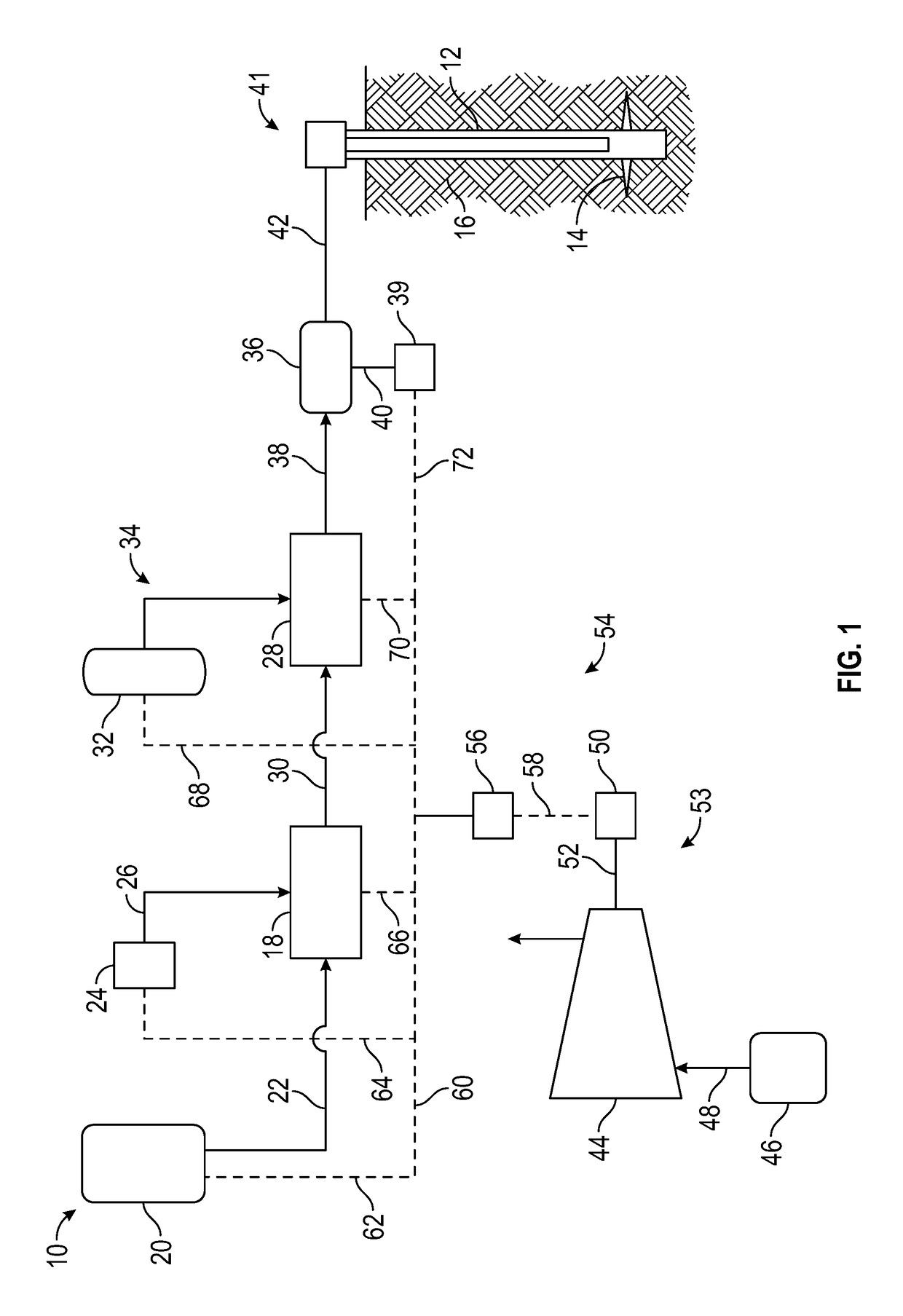

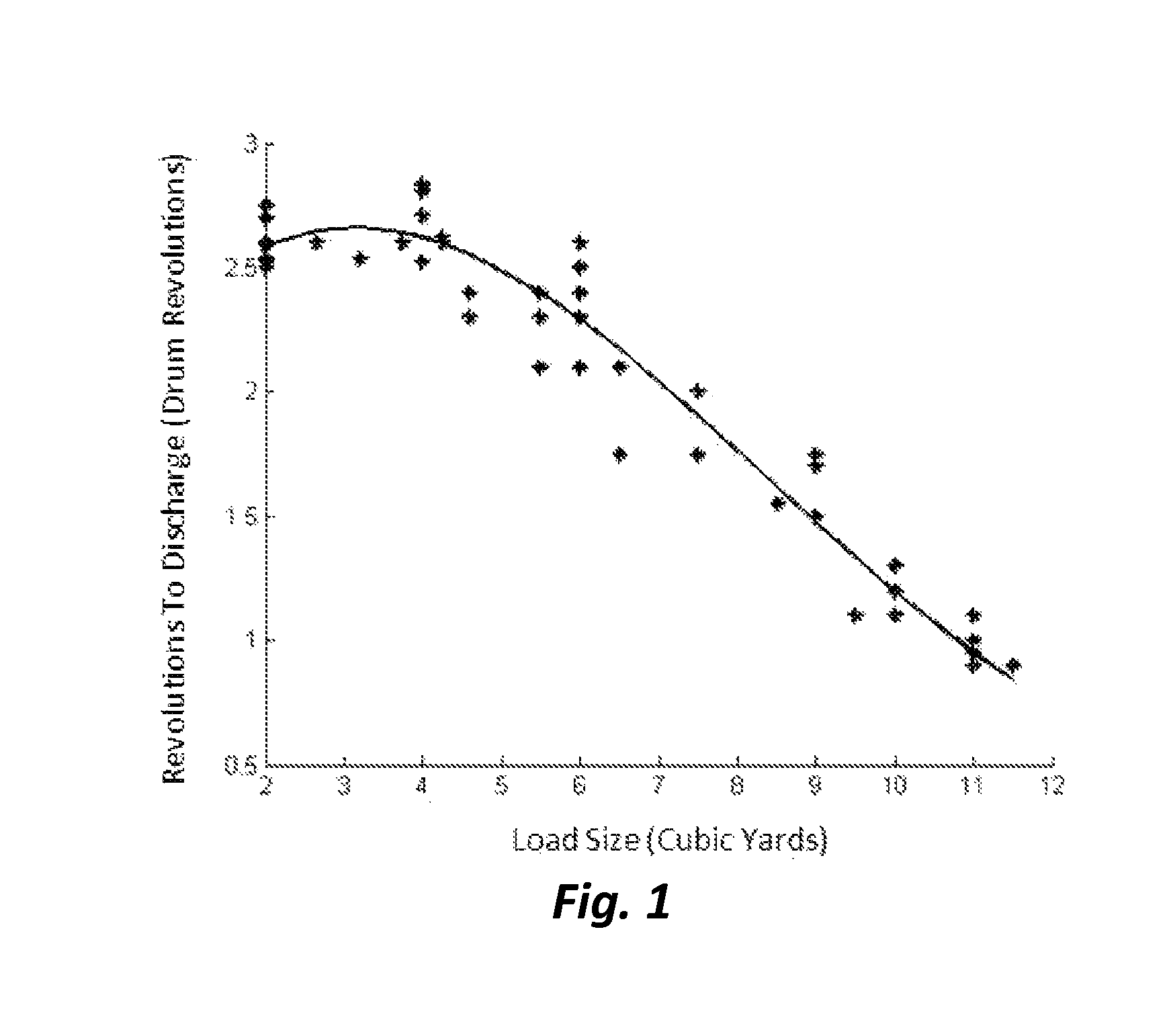

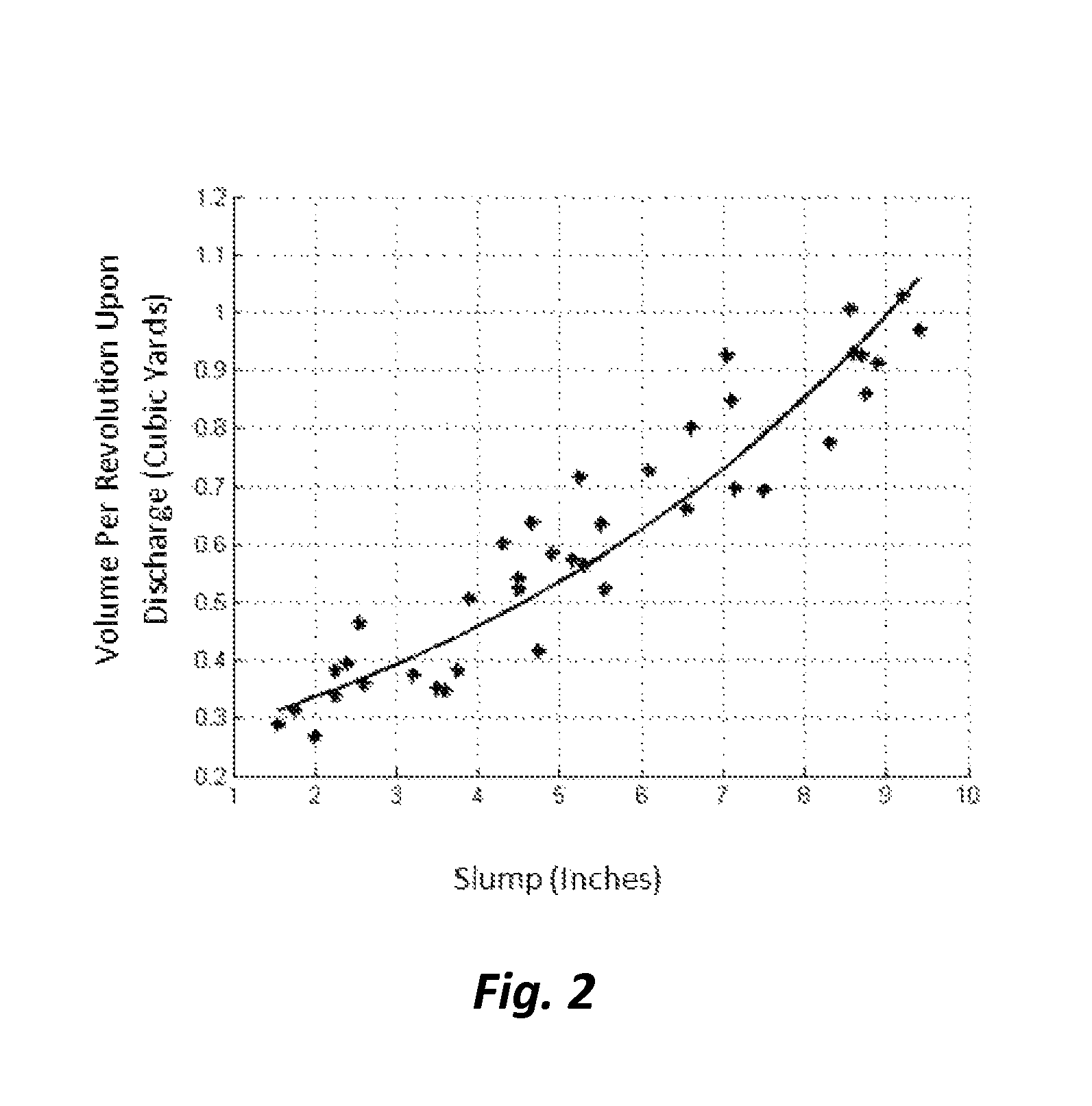

Disclosed are method and system for treating concrete in mixing drums of delivery vehicles having automated rheology (e.g., slump) monitoring systems programmed to dose fluids into concrete based on the monitored rheology. The present invention takes into account a Revolution-To-Discharge value (“RTD”) which reflects drum rotations needed to move concrete towards and through the mixing drum opening from which concrete is discharged, and also takes into consideration a Volume-Per-Revolution-Upon-Discharge (“VPRUD”) value which reflects the relation between the rate of discharge and rheology (e.g., slump) of concrete upon discharge. The invention is especially useful for reclaiming concrete in the drum after delivery and can confirm rheology based upon peak (maximum) discharge pressure. The present inventors found surprisingly that discharge pressure readings are useful for recalibrating automated rheology monitoring systems as well as for reporting and / or treating the remainder concrete.

Owner:VERIFI

Independent control of auger and hopper assembly in electric blender system

Embodiments relate to a hydraulic fracturing system that includes a blender unit. The system includes an auger and hopper assembly to receive proppant from a proppant source and feed the proppant to the blender unit for mixing with a fluid. A first power source is used to power the blender unit in order to mix the proppant with the fluid and prepare a fracturing slurry. A second power source independently powers the auger and hopper assembly in order to align the hopper of the auger and hopper assembly with a proppant feed from the proppant source. Thus, the auger and hopper assembly can be stowed or deployed without use of the first power source, which is the main power supply to the blender unit.

Owner:US WELL SERVICS LLC

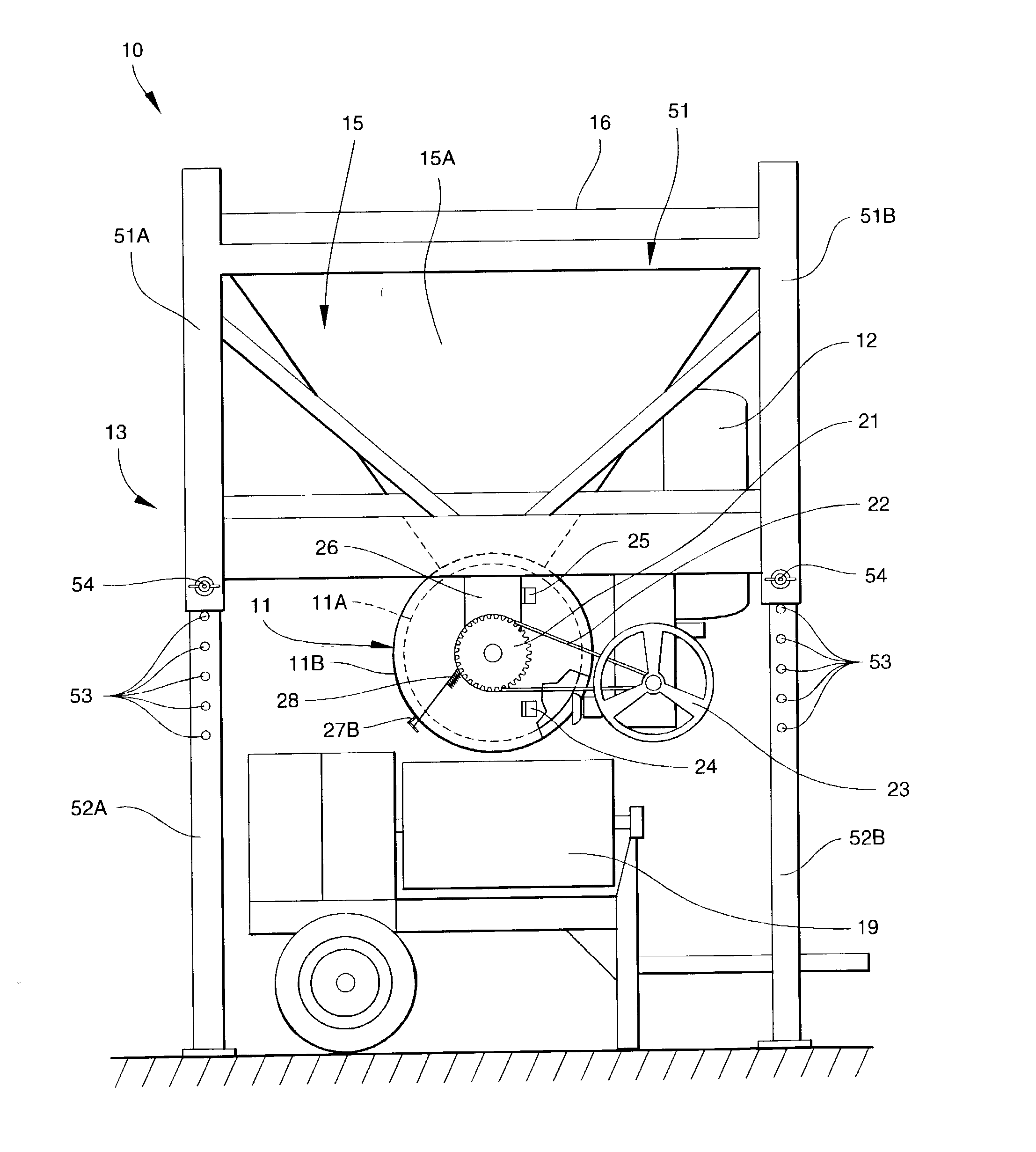

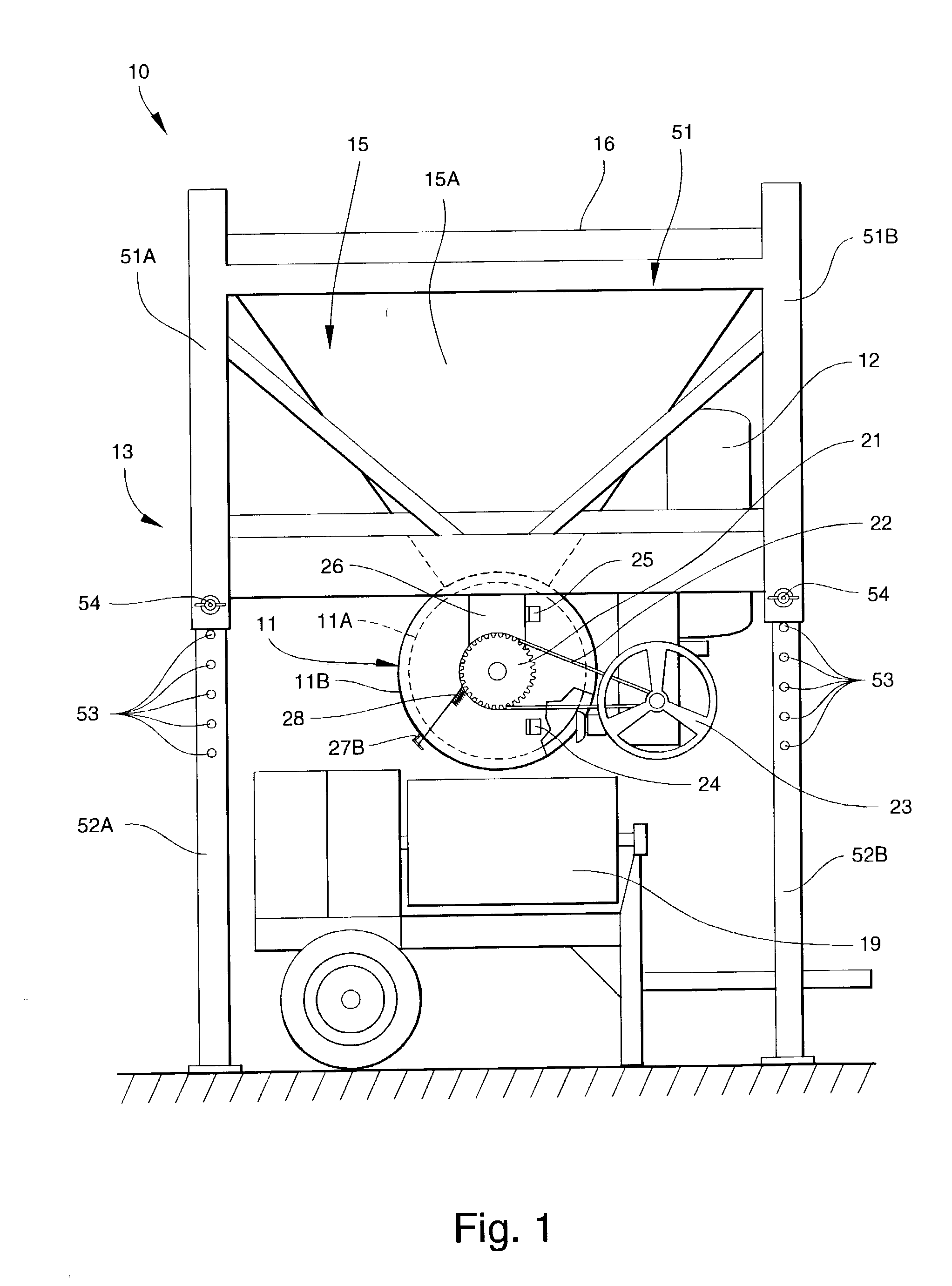

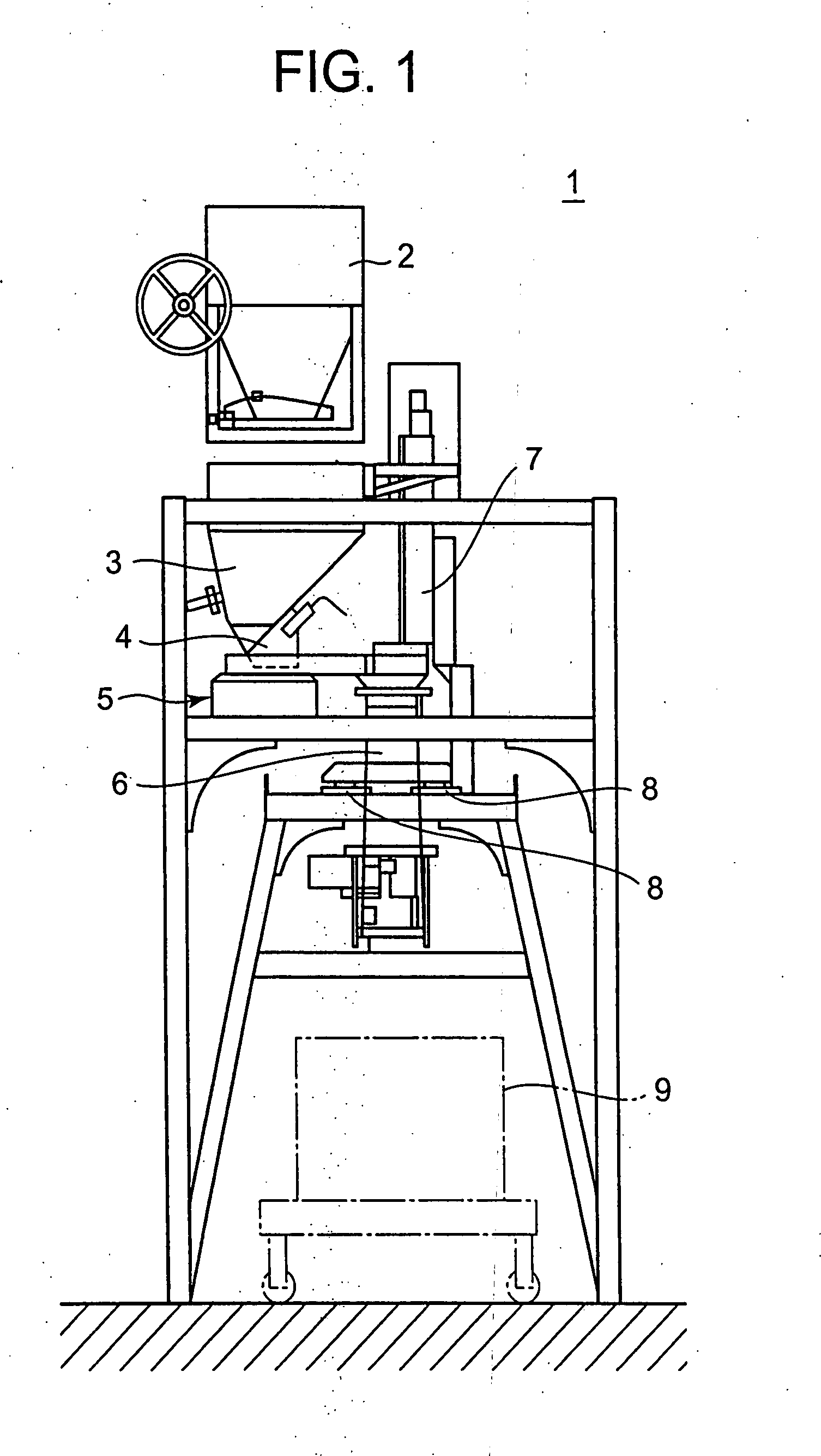

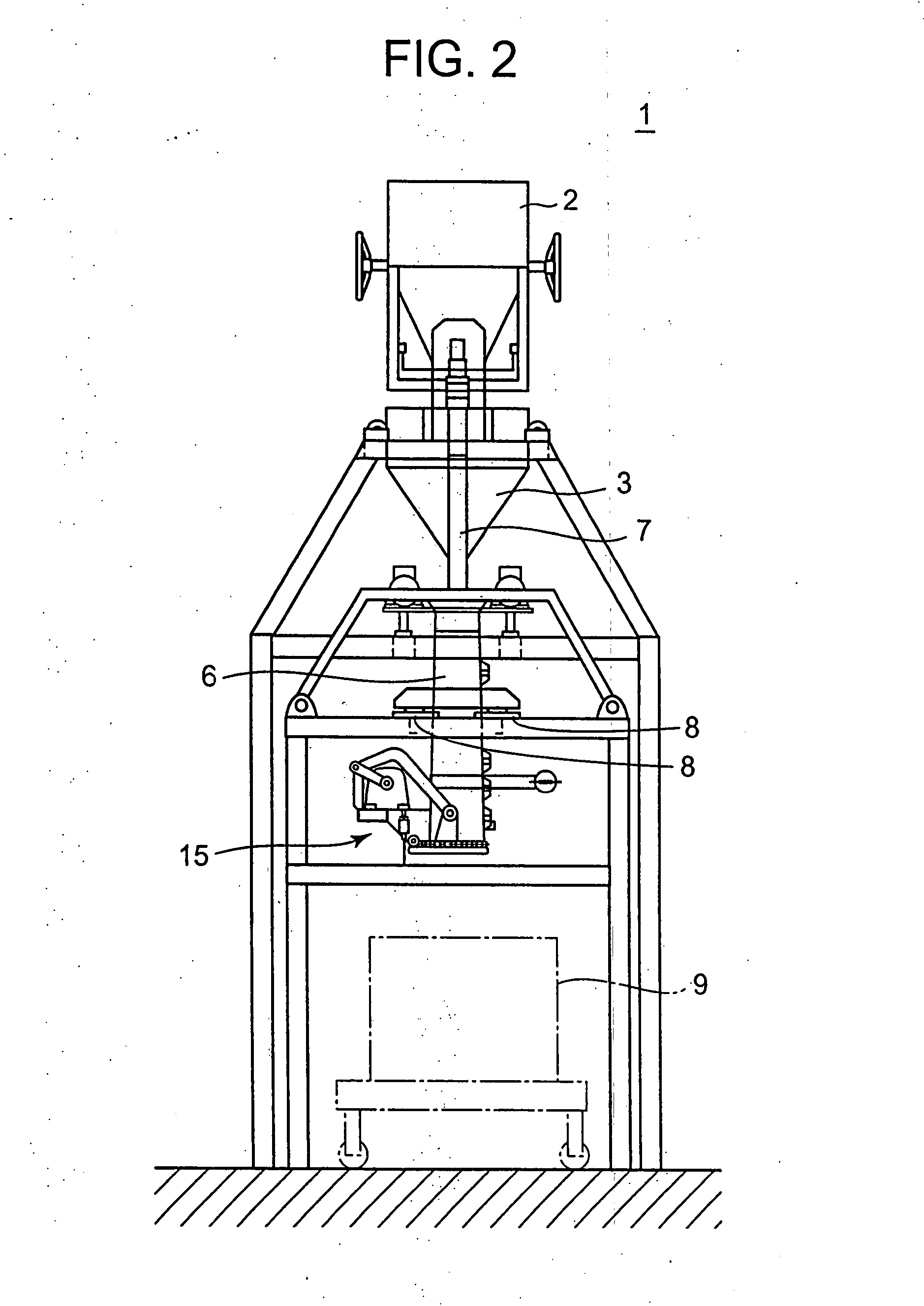

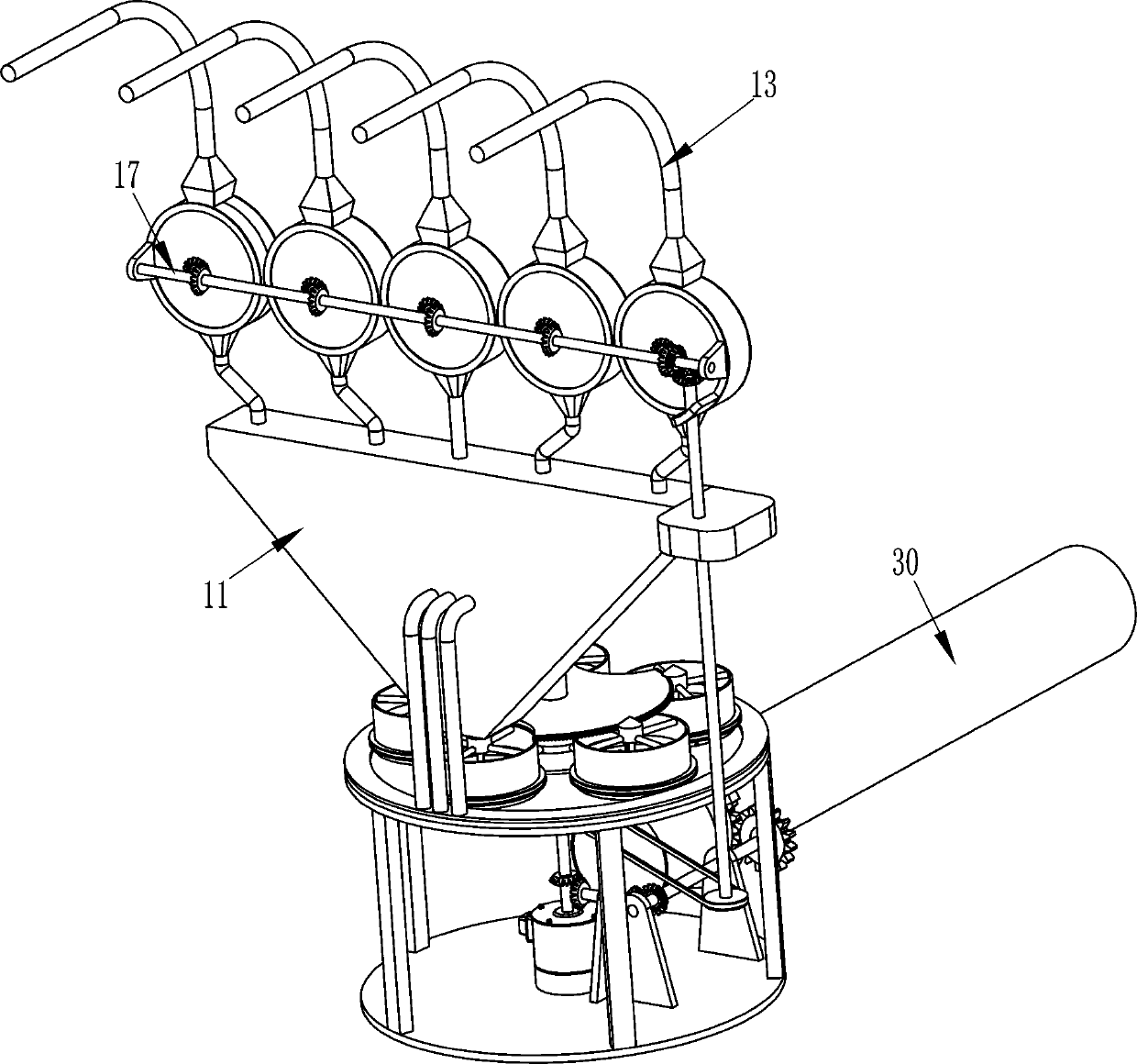

Volumetric mobile powder mixer

ActiveUS20170080601A1Transportation and packagingMixing operation control apparatusSolid componentEngineering

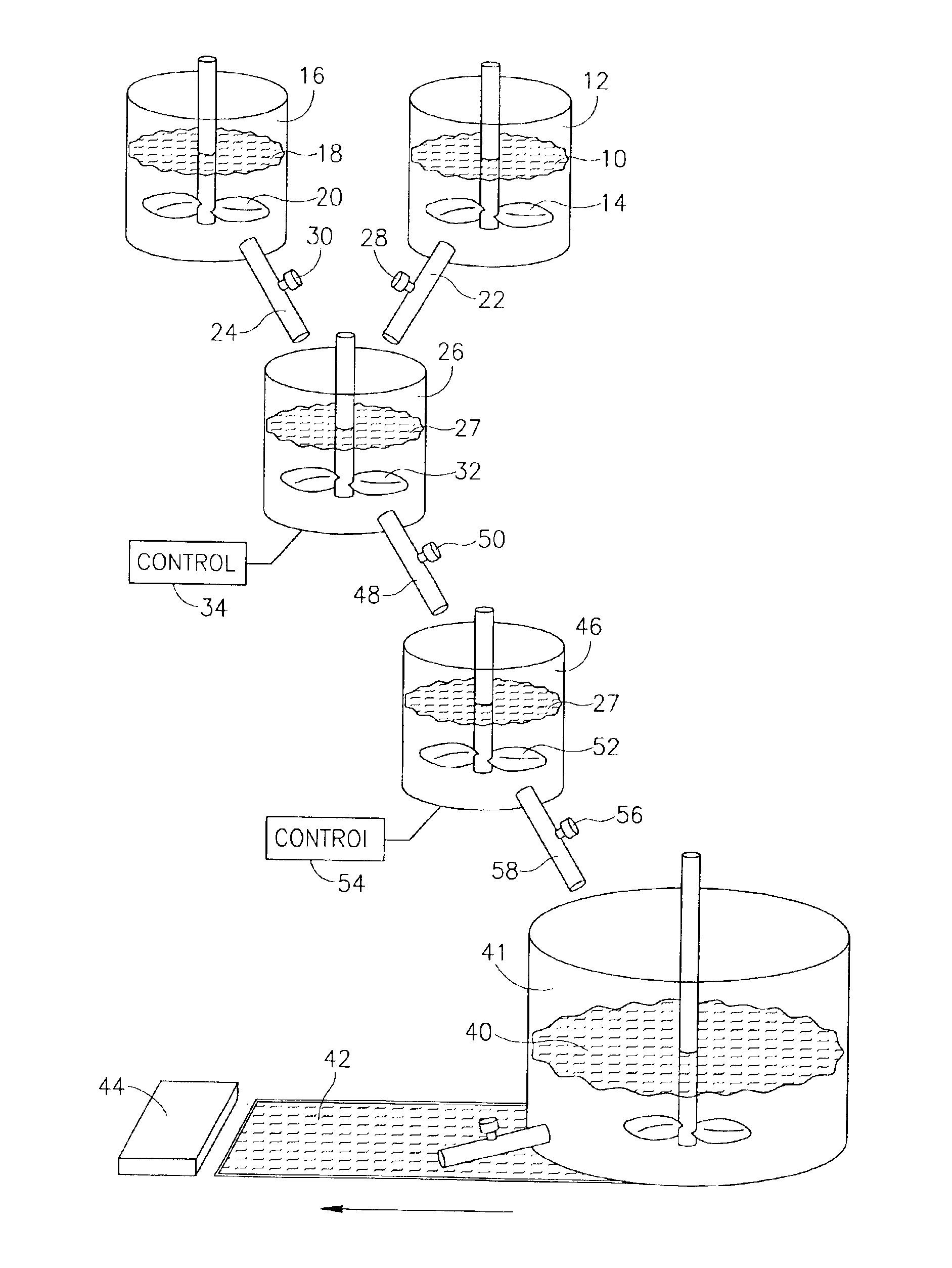

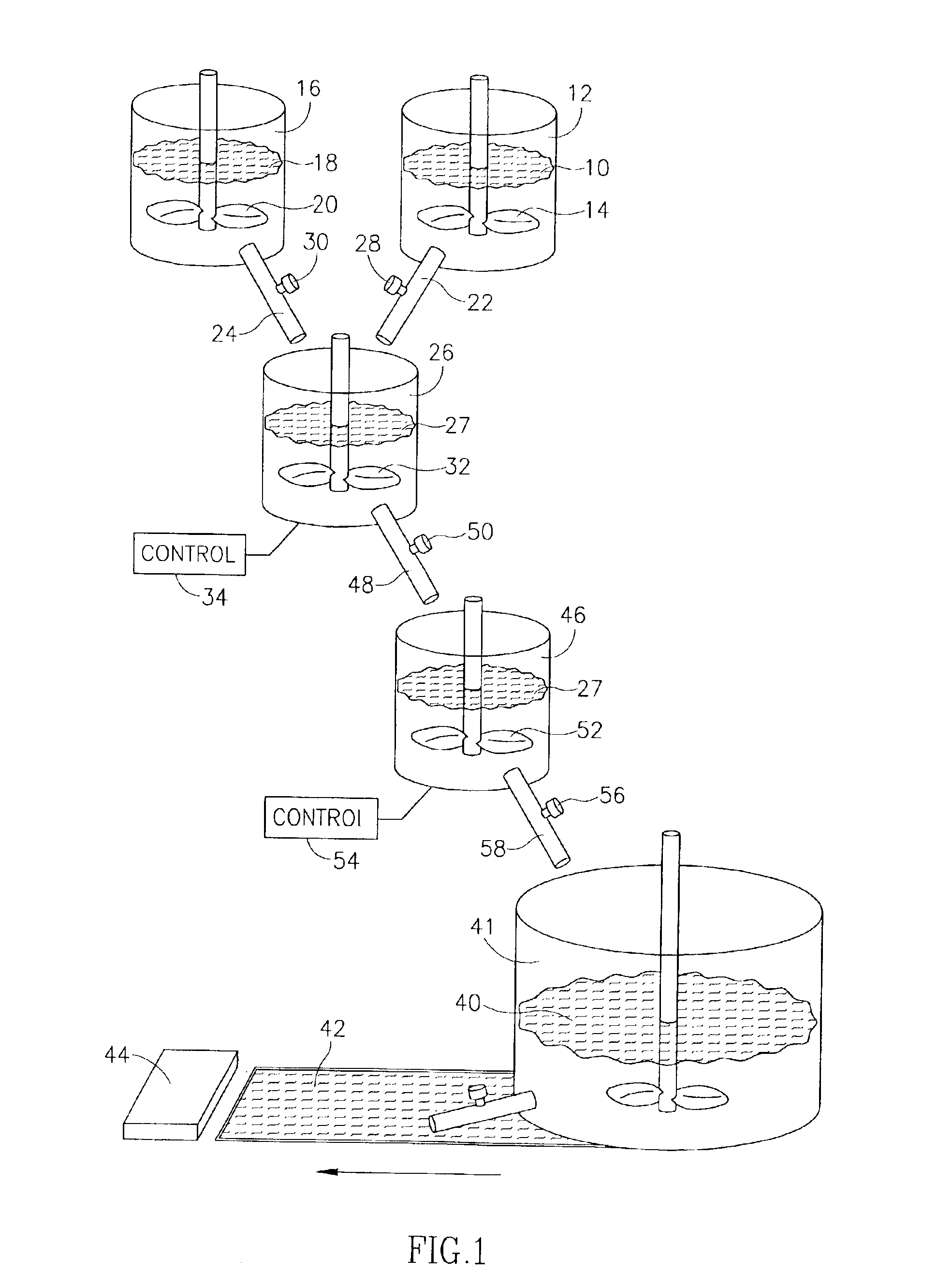

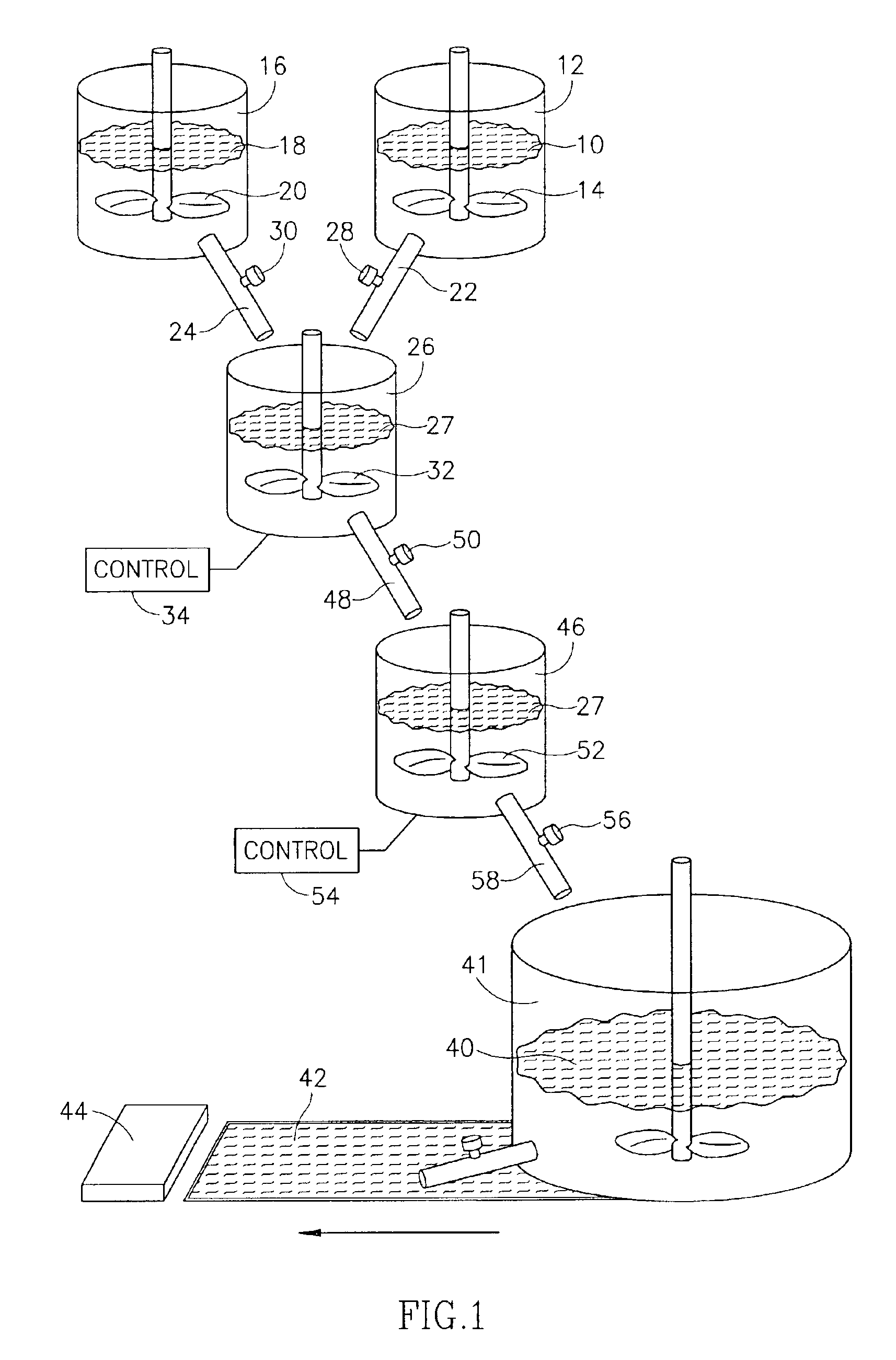

This disclosure describes volumetric mobile powder mixer (VMPM) systems and methods for VMPM operation and use. The VMPM is providing with a number of storage compartments (or bins) for liquid or solid ingredients including at least one powder storage bin, a powder transport system, a dust handling system, a solid / liquid mixing system, a cellular foam generator, a product delivery system, and a controller capable of monitoring the delivery and mixing of each of the ingredients, as well as the discharge of the final product. The controller determines if the proper mixture is being discharged by the VMPM and, if not, alerts the VMPM operator. In an automated embodiment, the VMPM controller is also configured to independently control the delivery and mixing of each of the ingredients, as well as the delivery of the final product.

Owner:EAGLE STRONG INVESTMENTS LLC

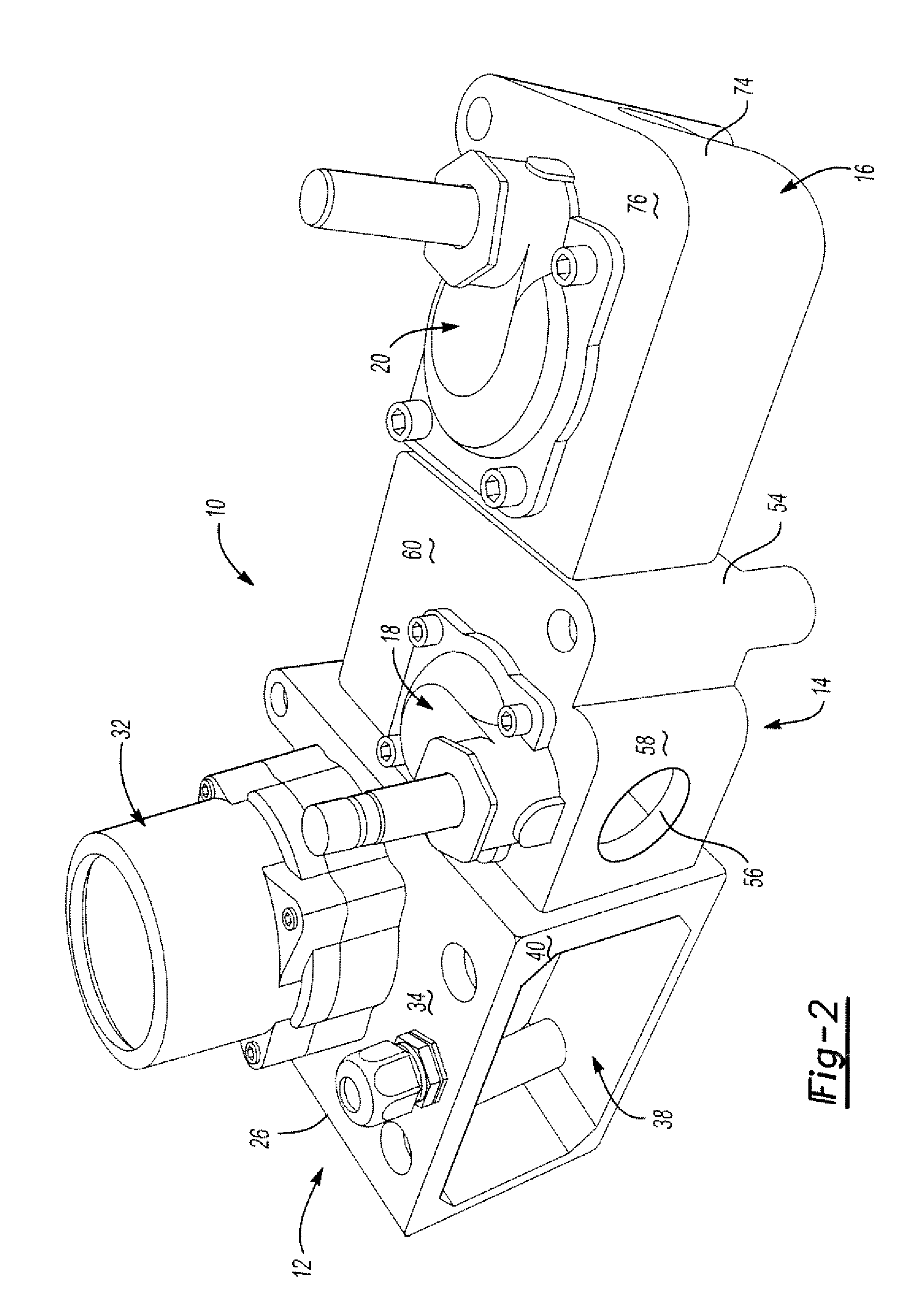

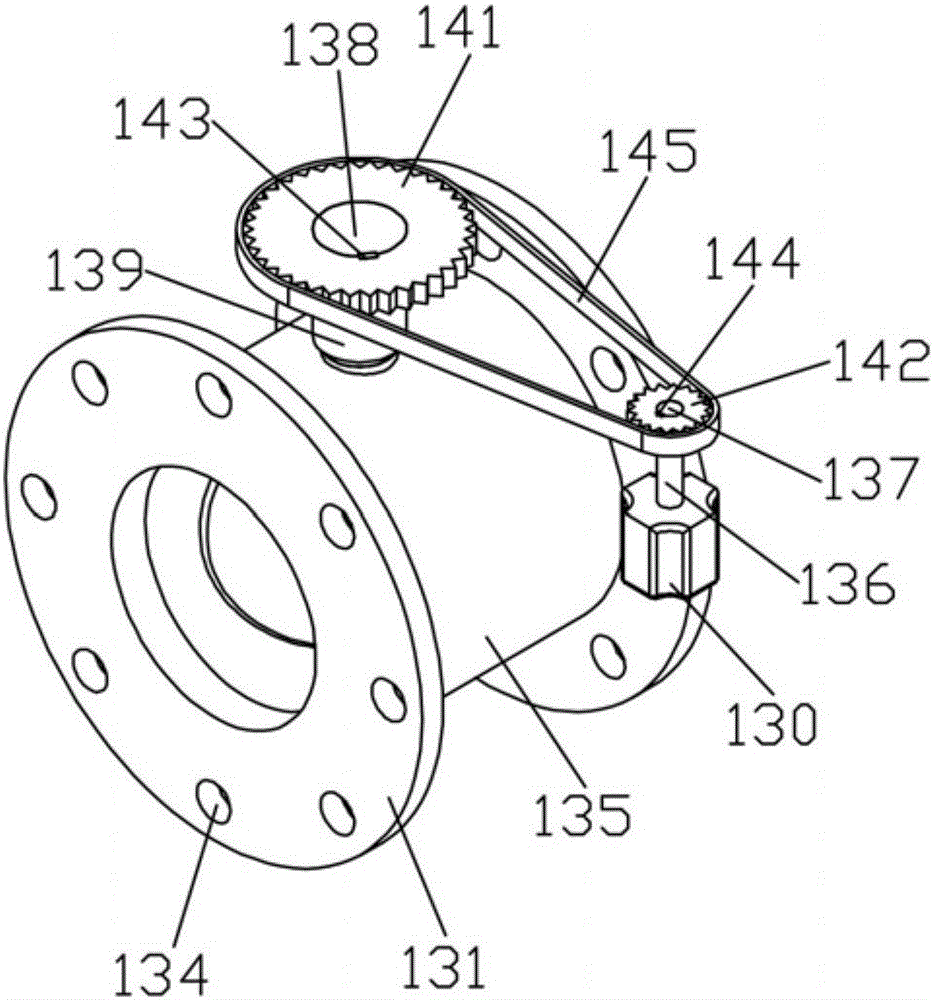

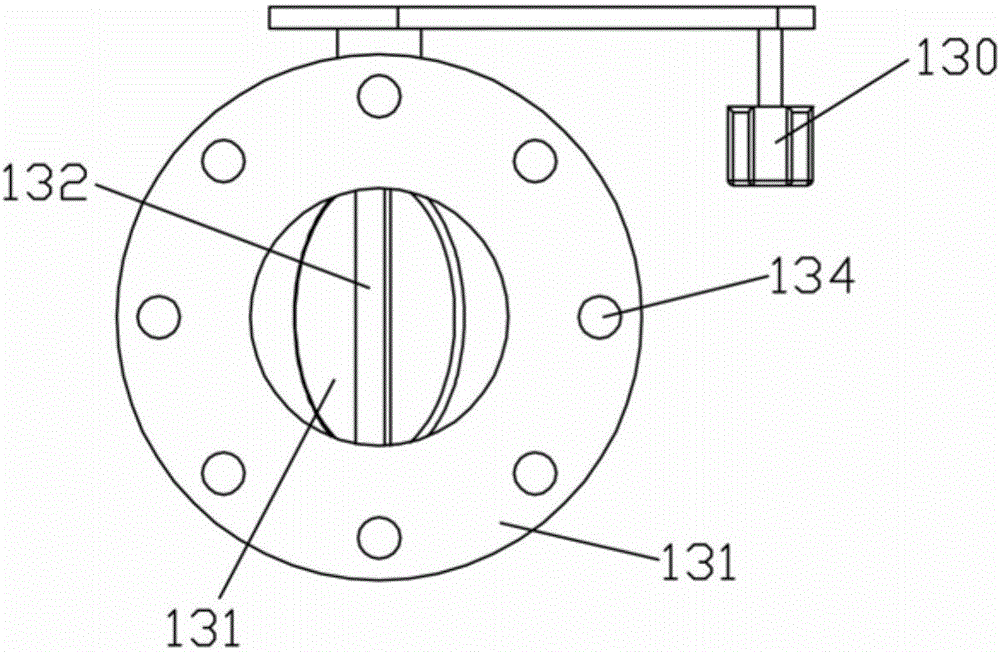

Water control apparatus

InactiveUS20080092957A1Facilitate communicationImprove accuracyControlling ratio of multiple fluid flowsMixing operation control apparatusEngineeringBiological activation

An embodiment of a water control apparatus is disclosed that may be used with a concrete mixing assembly. The apparatus may include flowmeter unit and a normally closed valve unit. The normally closed valve unit may be in fluid communication with, and removably connected to, the flowmeter unit. A control unit may be provide that may monitor the flowmeter unit and electronically control the opening and close of the normally closed valve unit. A switch may be also provided that may electrically communicate with the control unit. The activation of the switch being operable to cause the normally closed valve to open and result in the flow of water into a concrete mixing drum that is in fluid communication with the normally closed valve.

Owner:ROSAEN LARS

Treating and reporting volume of concrete in delivery vehicle mixing drum

ActiveUS9550312B2Novel convenient highly accurate methodAccurate and convenient methodDischarging apparatusMixing operation control apparatusDelivery vehicleMonitoring system

Disclosed are method and system for treating concrete in mixing drums of delivery vehicles having automated rheology (e.g., slump) monitoring systems programmed to dose fluids into concrete based on the monitored rheology. The present invention takes into account a Revolution-To-Discharge value (“RTD”) which reflects drum rotations needed to move concrete towards and through the mixing drum opening from which concrete is discharged, and also takes into consideration a Volume-Per-Revolution-Upon-Discharge (“VPRUD”) value which reflects the relation between the rate of discharge and rheology (e.g., slump) of concrete upon discharge. The invention is especially useful for reclaiming concrete in the drum after delivery and can confirm rheology based upon peak (maximum) discharge pressure. The present inventors found surprisingly that discharge pressure readings are useful for recalibrating automated rheology monitoring systems as well as for reporting and / or treating the remainder concrete.

Owner:VERIFI INC

Gypsum product and method therefor

InactiveUS6902615B2Large energyLimited shelf lifeOther chemical processesSolid waste managementVolumetric Mass DensityReducer

A method comprising adding a suspension of a hydrophobic substance to a gypsum slurry. The hydrophobic substance may impart water repellent characteristics to the gypsum, may be used as a foaming aid, density reducer, dimension stabilizer, and others, and may increase the mechanical strength and durability of the gypsum product. In another embodiment of the present invention, suspensions of other substances may be used in addition to or in place of the hydrophobic substance to impart these characteristics.

Owner:TIP - THE IND PIVOT

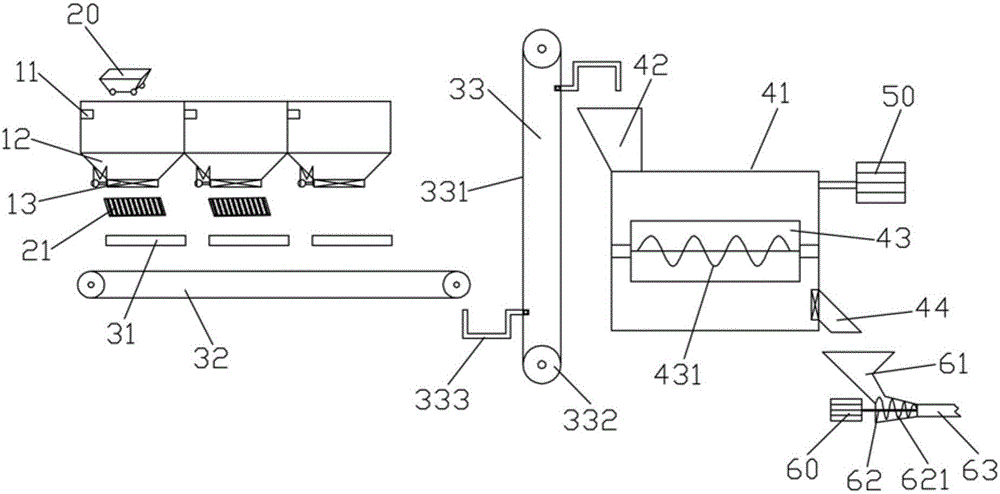

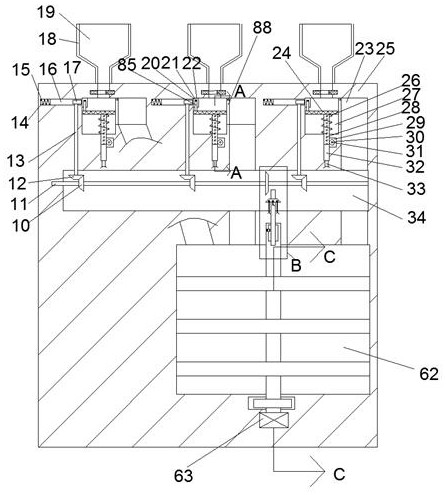

Automatic proportioning system of concrete mixing station

ActiveCN105690568AAccurate weighingPrecise deliveryDischarging apparatusMixing operation control apparatusControl systemBucket elevator

The invention discloses an automatic proportioning system of a concrete mixing station. The automatic proportioning system comprises a raw material storage system, a raw material weighing system, a mixer system, a raw material conveying system and a control system, wherein the raw material storage system comprises three silos which are arranged side by side; the raw material conveying system is composed of a belt conveyor and a bucket elevator; and the raw material weighing system comprises three belt weighers which are positioned above the belt conveyor, and are positioned below the openings of the silos. The automatic proportioning system can meet a large-scale concrete manufacturing process, can be used for precisely weighing and conveying various raw materials, and further can realize precise control and efficient management on a concrete proportioning process while the product quality is guaranteed, so that the problems such as a complex and out-of-order procedure in a convention producing and proportioning process, confused record management in a proportioning process, severe proportioning resource waste and the like are obviously avoided.

Owner:陕西恒盛混凝土有限公司

Water control apparatus

InactiveUS7530728B2Meet the requirementsObviates abilityMixing operation control apparatusRatio controlElectricityEngineering

Owner:ROSAEN LARS

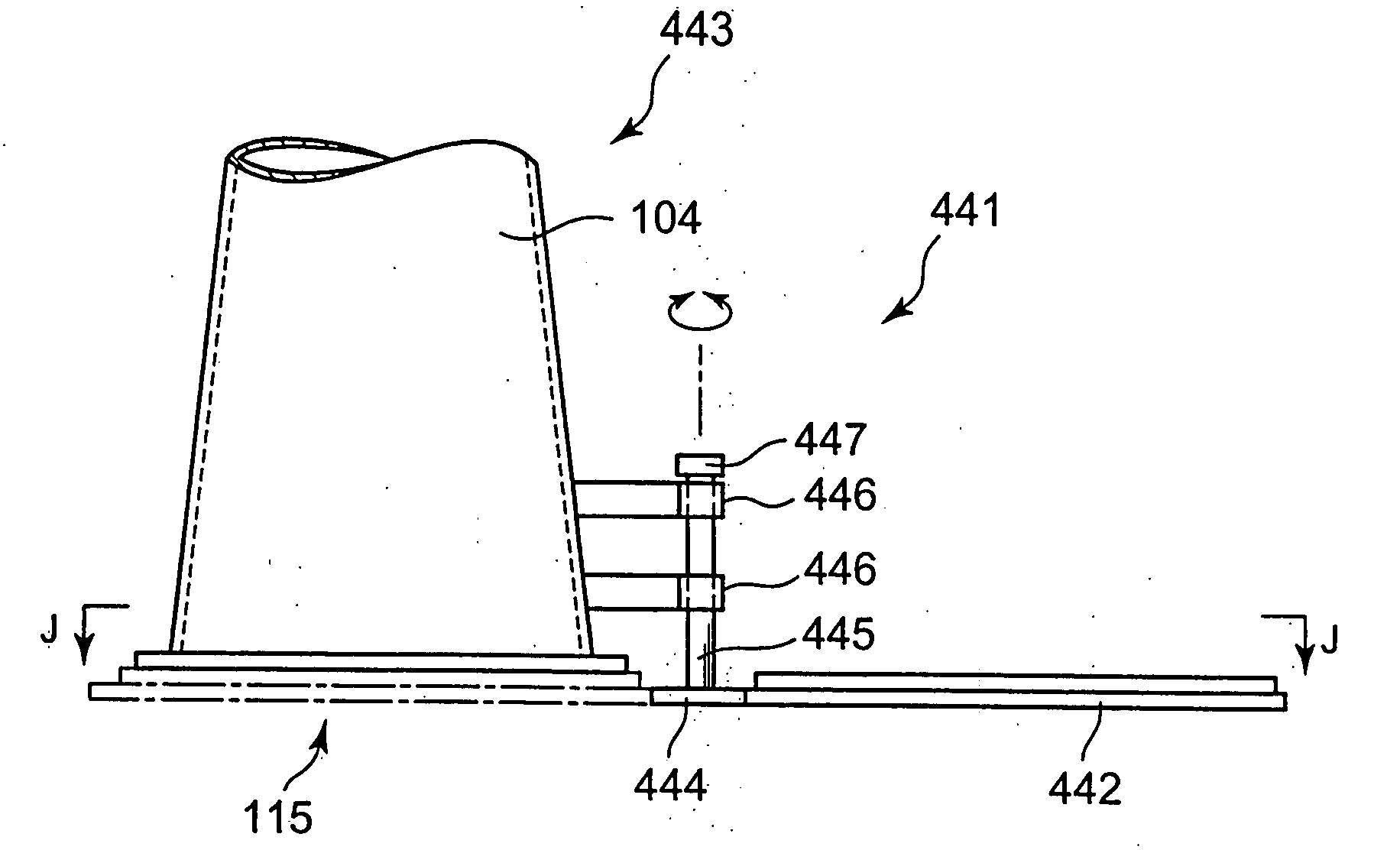

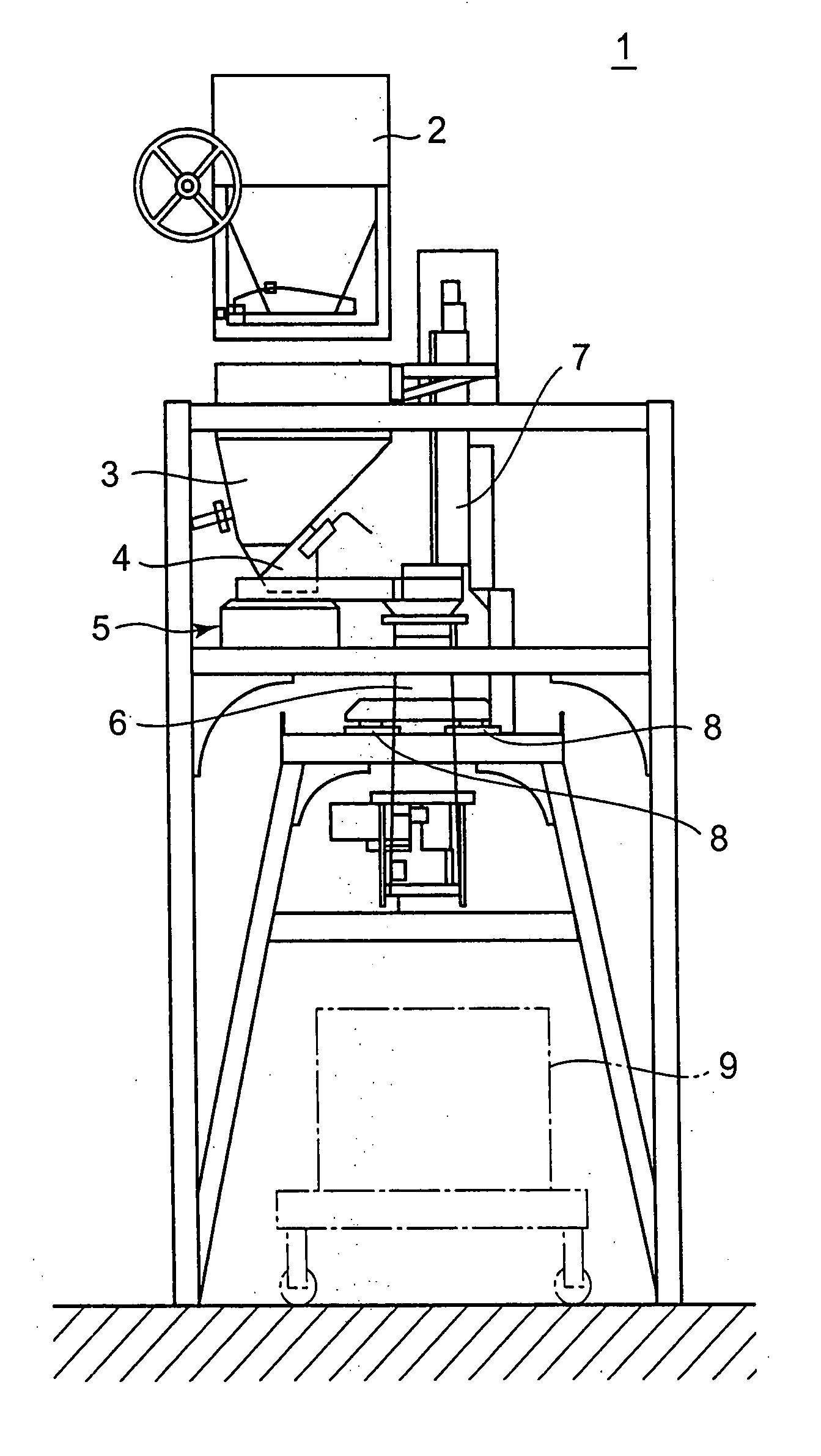

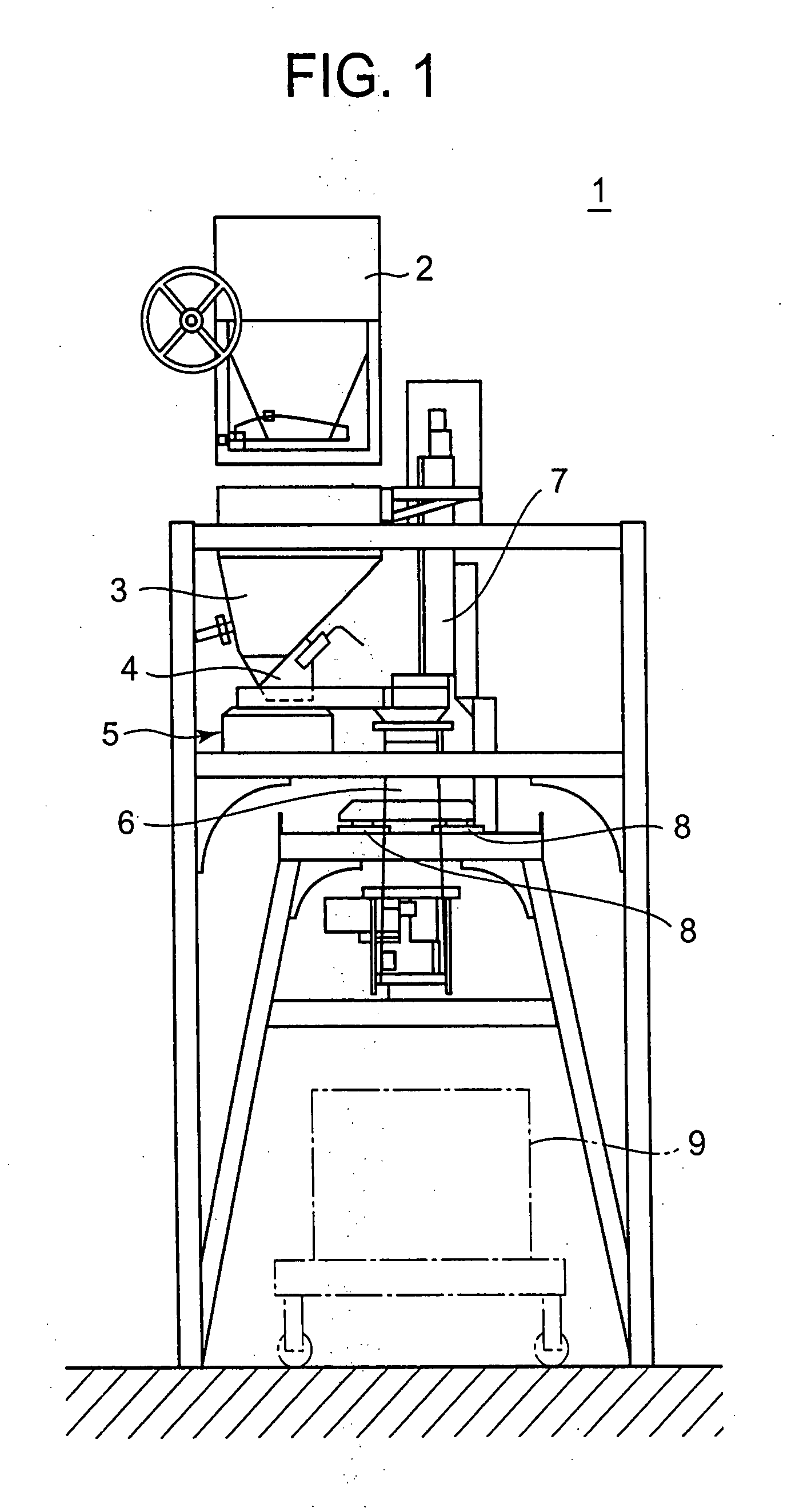

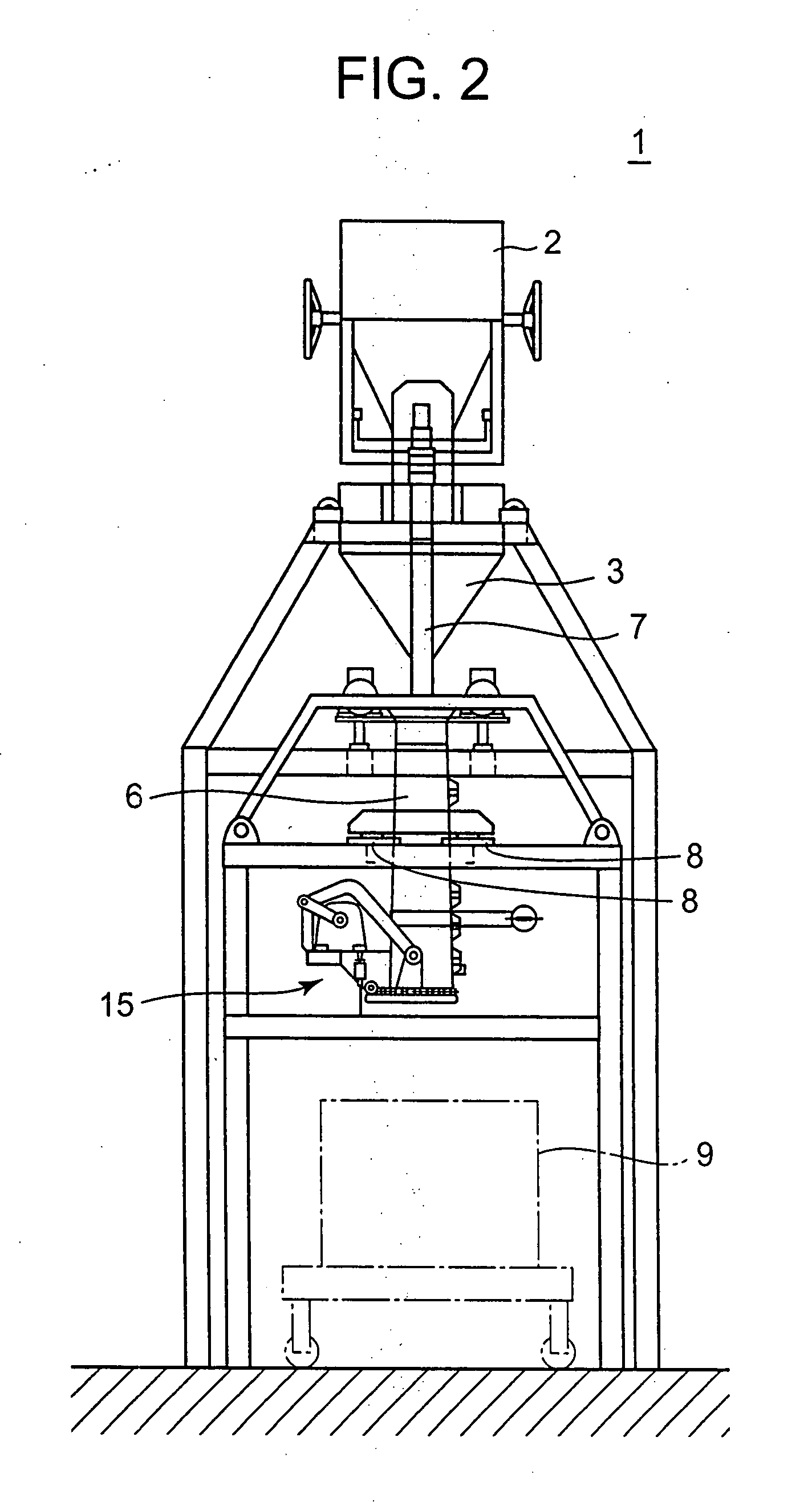

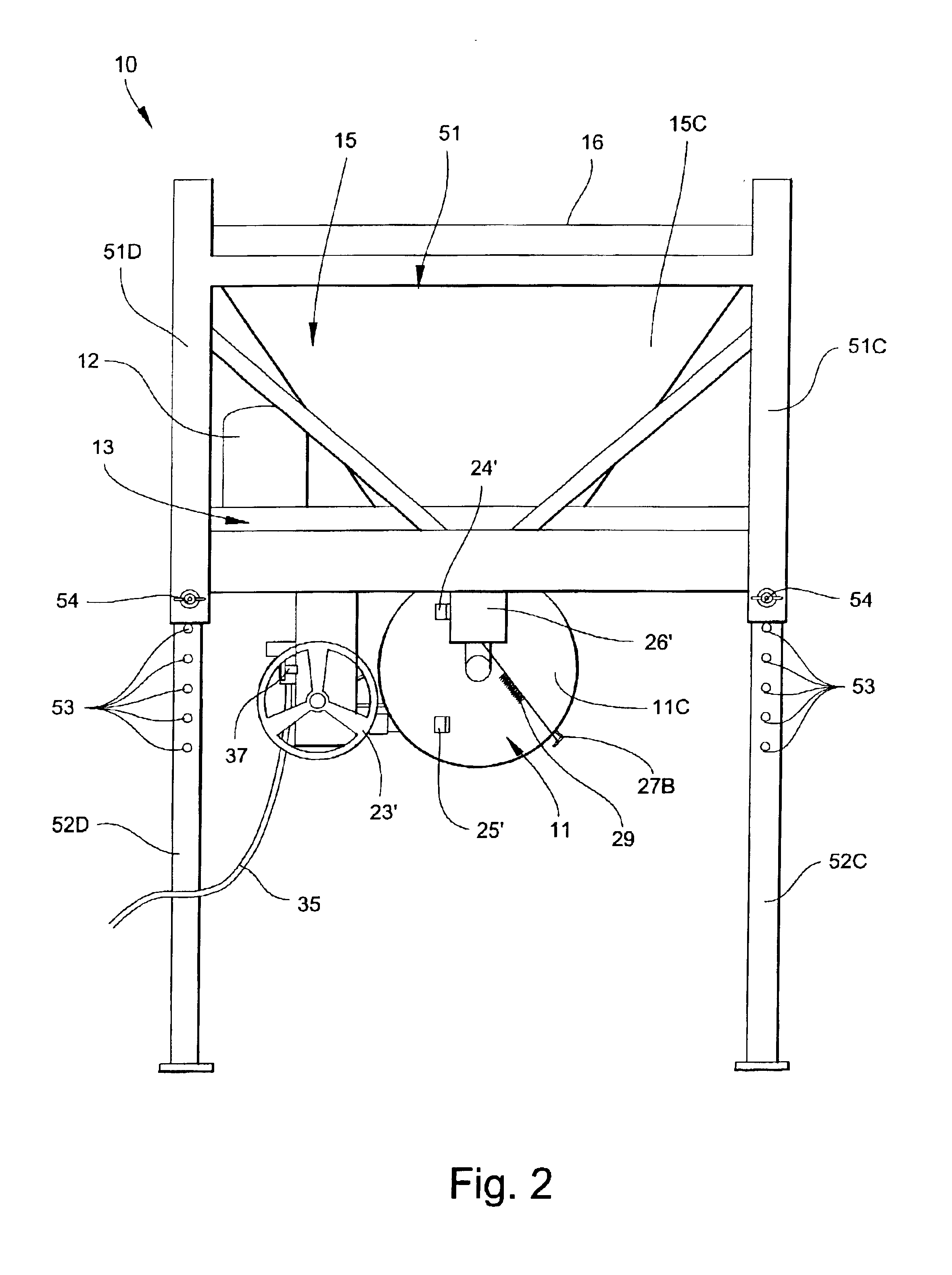

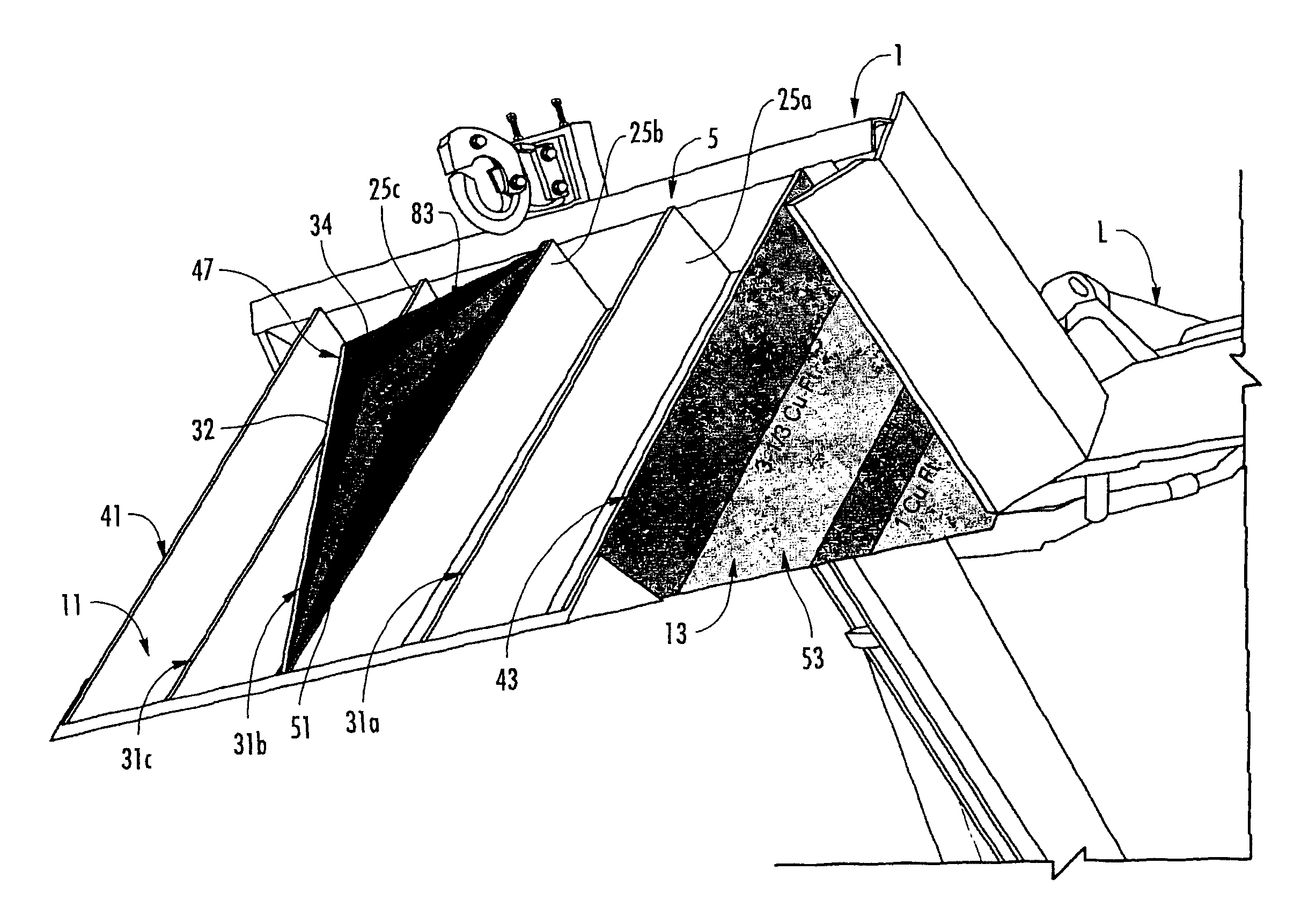

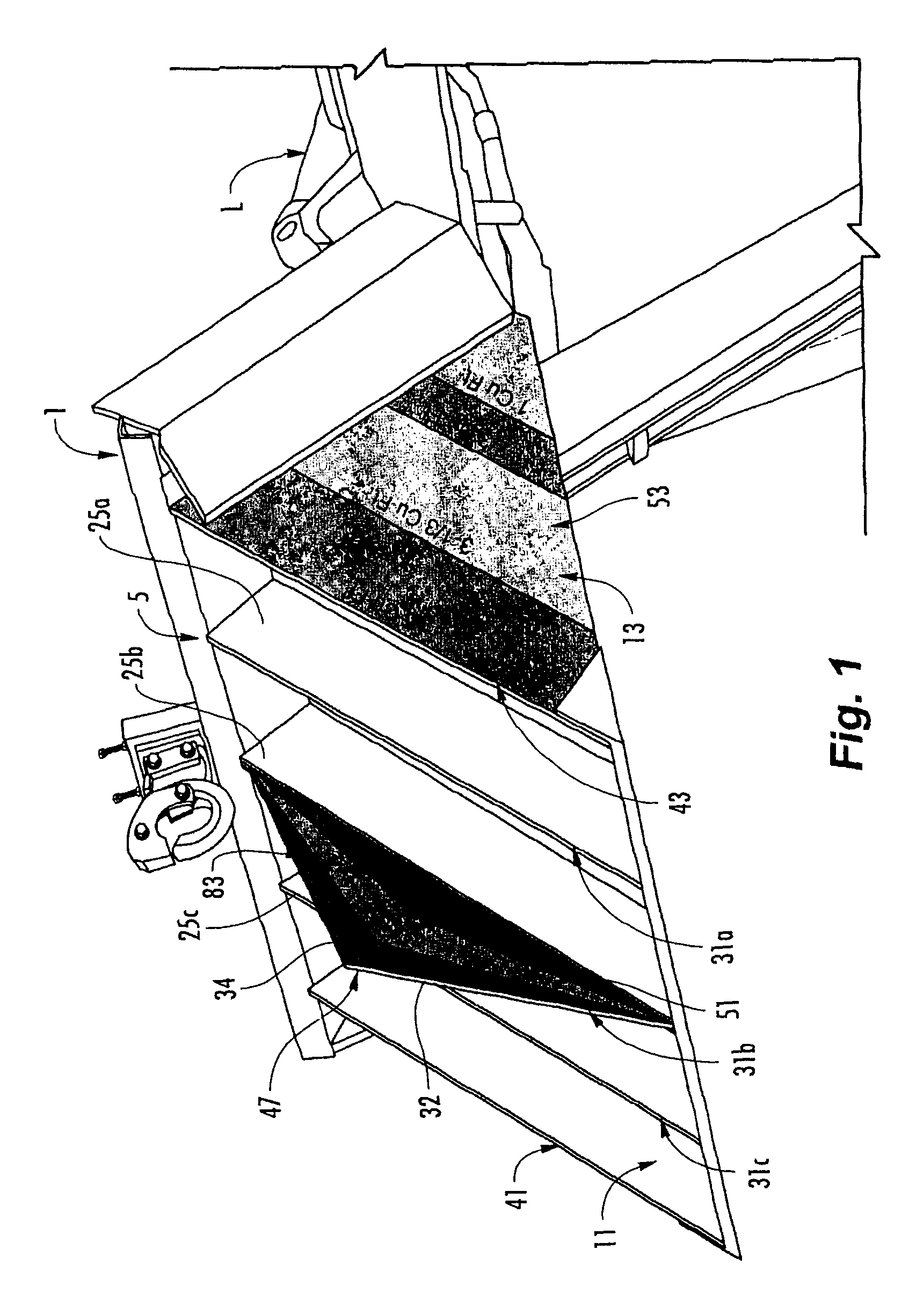

Volumetric solid and liquid dispenser

InactiveUS20040100857A1Reducing and eliminating riskMinimize risk of injuryControlling ratio of multiple fluid flowsMixing operation control apparatusEngineeringMechanical engineering

A volumetric solid and liquid dispenser includes a drum sized for receiving and containing a predetermined volume of solid material from a solid material supply source. The supply source can be a hopper positioned above the drum. The drum is rotatably mounted to a support frame and can be rotated from a position in which it receives solid material from the supply source to a dispensing position in which it dispenses the solid material into a receptacle below. A liquid metering and dispensing container dispenses a predetermined volume of liquid into the receptacle for mixing with the solid material. The invention is particularly useful for dispensing predetermined volumes of sand and water into a cement mixer for mixing with mortar.

Owner:HARRIS ARCHIE J

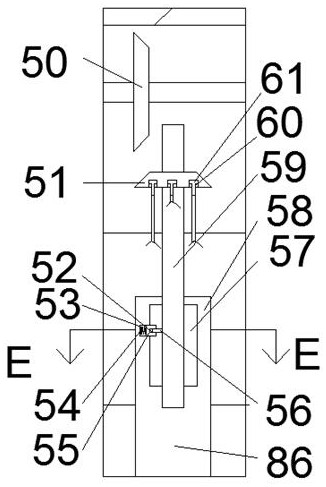

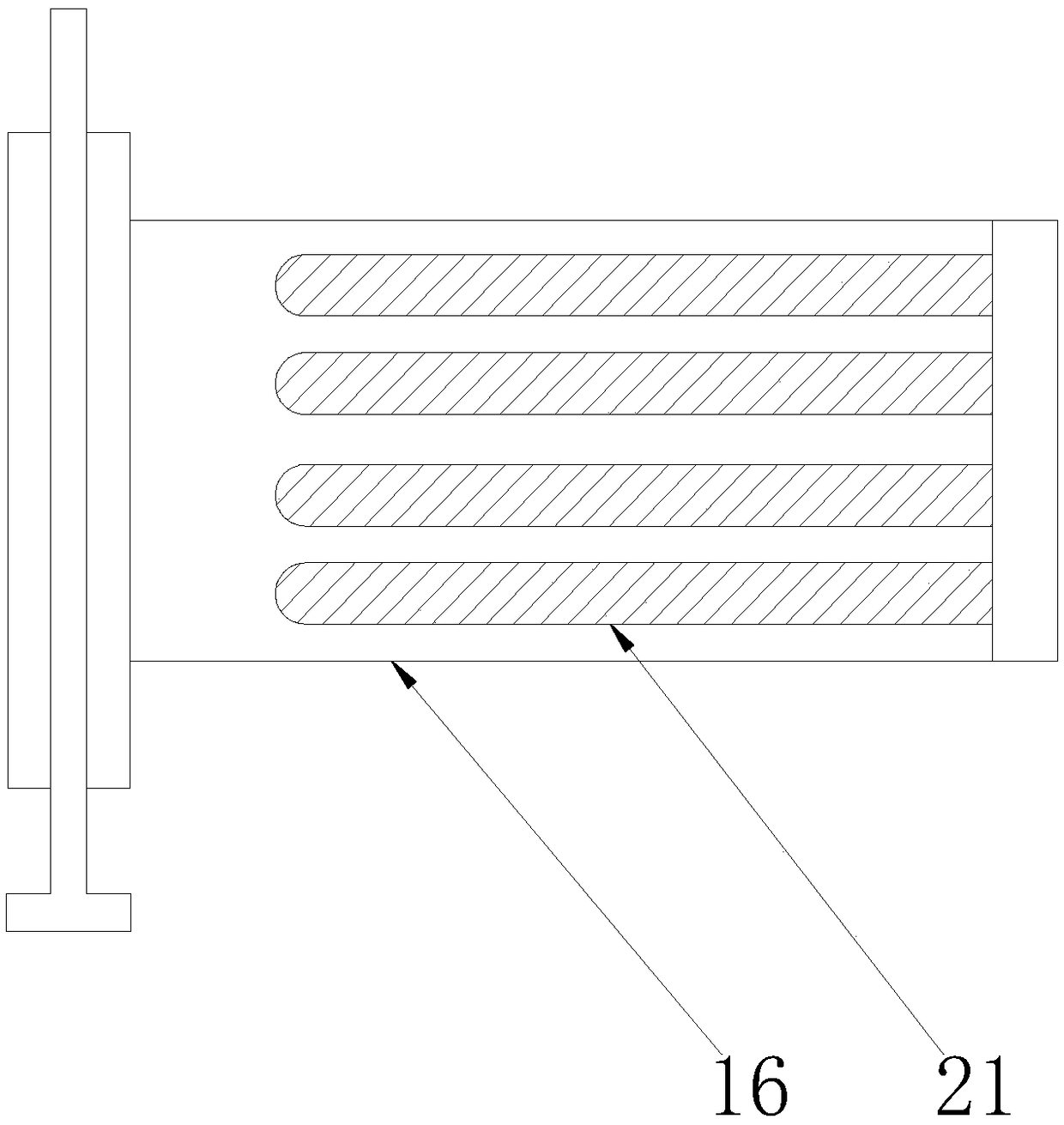

Measuring apparatus and measuring method for concrete-forming materials

InactiveUS20070163333A1Accurate measurementAccurate massWeighing apparatus for materials with special property/formSpecific gravity measurementMeasurement deviceEngineering

A measuring apparatus of submergence aggregate according to the present invention comprising a stock bin for storing fine aggregate, a fine aggregate feed hopper placed under the stock bin, a vibrating feeder placed under a discharge opening of the fine aggregate feed hopper, a screen device placed in the vicinity of an exit of the vibrating feeder, a measurement tank placed under the screen device, an electrode-type displacement sensor as means for measuring a water level placed above the measurement tank, and load cells as mass measuring means for measuring a mass of the measurement tank.

Owner:OBAYASHI CORP

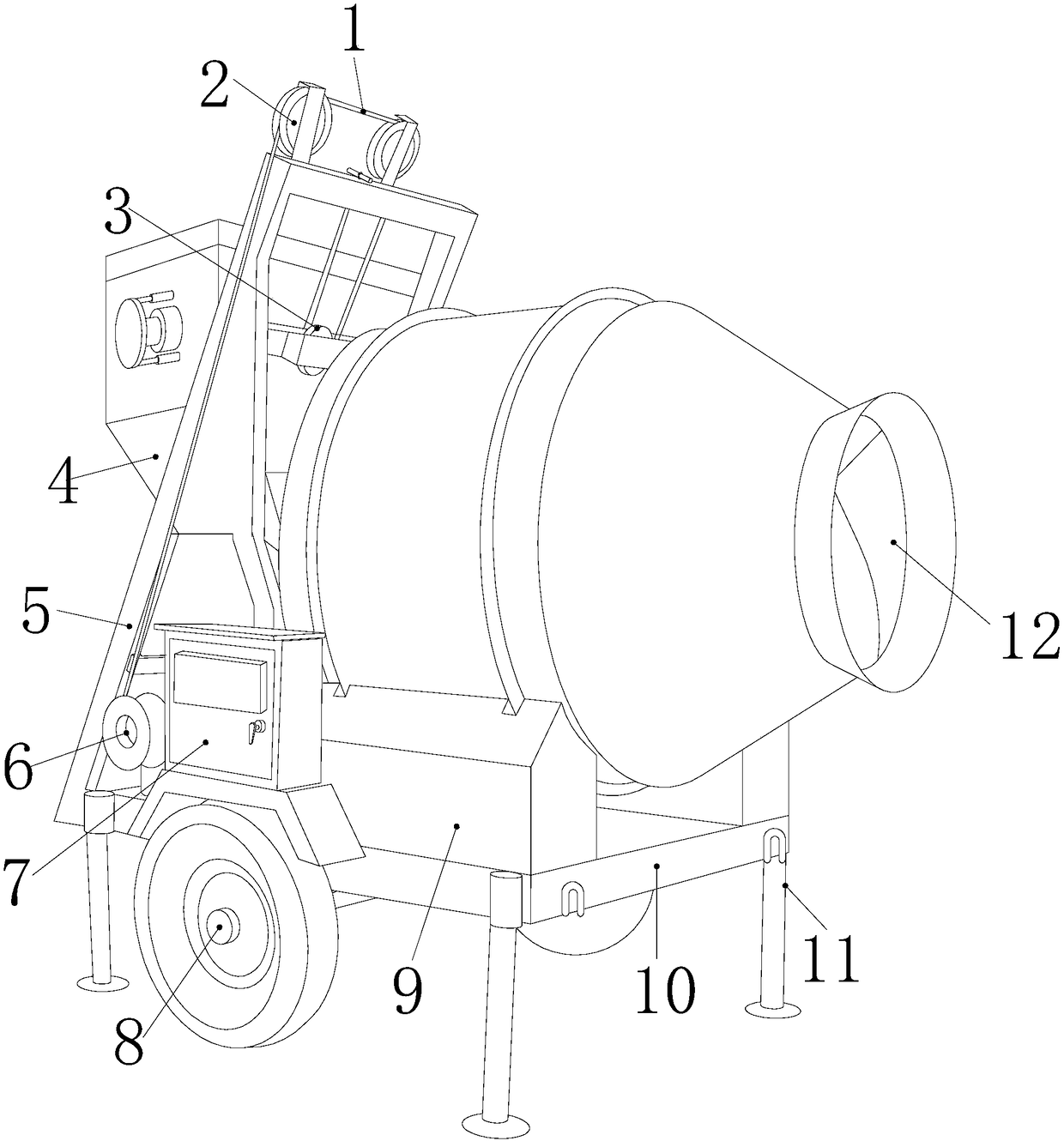

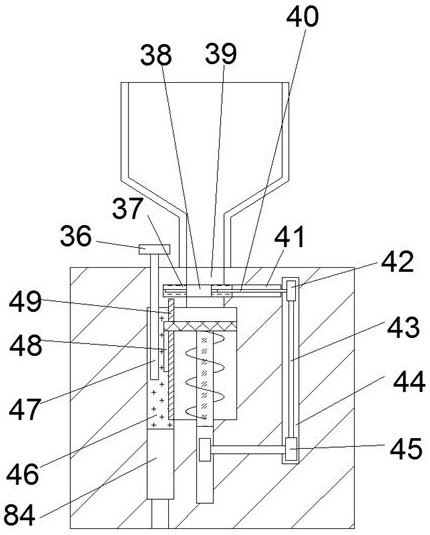

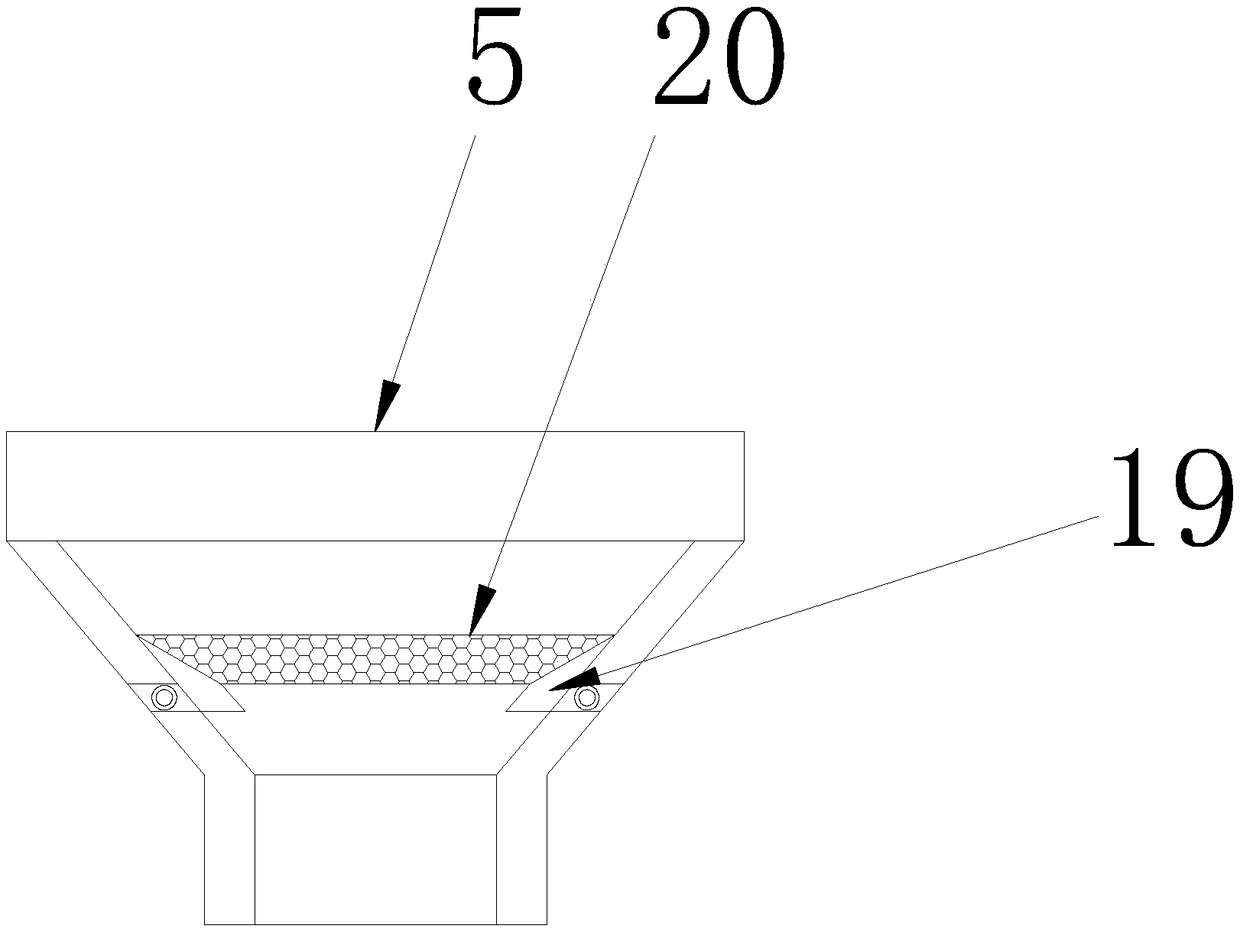

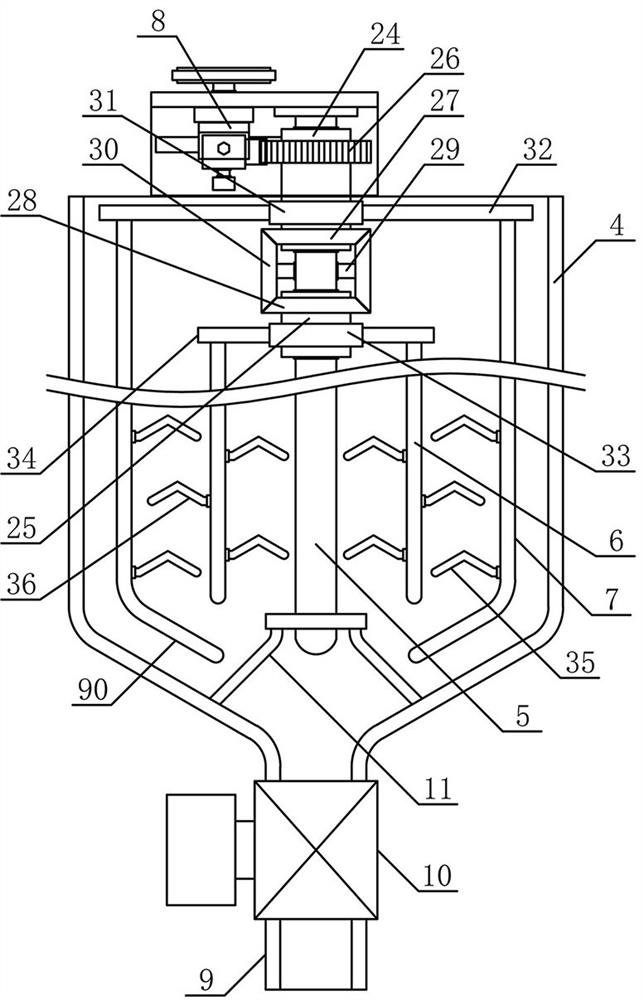

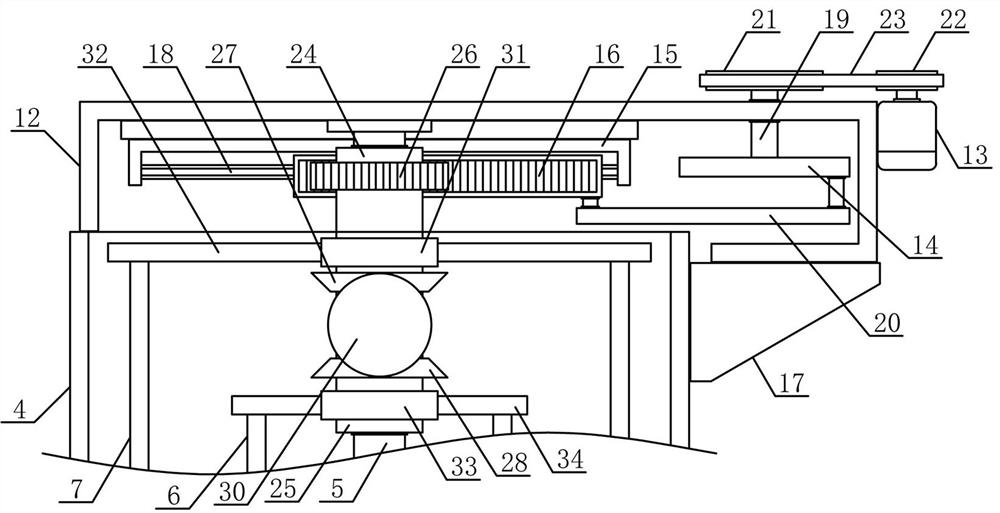

Quantitative concrete stirring device for construction machinery

InactiveCN108527655AQuality is not affectedQuality impactMixing operation control apparatusCement mixing apparatusDrive wheelArchitectural engineering

The invention discloses a quantitative concrete stirring device for construction machinery. The quantitative concrete stirring device for the constructive machinery structurally comprises a steel wirerope, a fixed pulley, a movable pulley, a dustproof quantifying device, a channel steel frame, a hoisting motor, a controller, a driving wheel device, a rotary guiding rack, a base, four supporting legs and a stirring barrel; the four supporting legs which are perpendicular to the base are separately welded to four corner portions of the bottom surface of the base; driving wheel devices are arranged among the four supporting legs; and the driving wheel devices and the bottom surface of the base are connected together in a mechanical connection mode. The quantitative concrete stirring device for the construction machine is provided with a closable dustproof quantifying device, and has a dustproof function, and can be started when required and closed when in an idle state, dust and impurities are effectively prevented from dropping in a feed bin, the water and cement stirring effect is improved favorably, and thus, the quality of the stirred concrete is not affected.

Owner:南安泊阅工业设计有限公司

Gypsum product and method therefor

InactiveUS6932863B2Large energyLimited shelf lifeOther chemical processesSolid waste managementSlurryWater resistant

A method for making a gypsum product water resistant, the method comprising adding a suspension of a hydrophobic substance to a gypsum slurry.

Owner:TIP - THE IND PIVOT

Measuring apparatus and measuring method for concrete-forming materials

InactiveUS20070186697A1Accurate measurementAccurate massWeighing apparatus for materials with special property/formWeighing apparatus for continuous material flowMeasurement deviceEngineering

A measuring apparatus of submergence aggregate according to the present invention comprising a stock bin for storing fine aggregate, a fine aggregate feed hopper placed under the stock bin, a vibrating feeder placed under a discharge opening of the fine aggregate feed hopper, a screen device placed in the vicinity of an exit of the vibrating feeder, a measurement tank placed under the screen device, an electrode-type displacement sensor as means for measuring a water level placed above the measurement tank, and load cells as mass measuring means for measuring a mass of the measurement tank.

Owner:OBAYASHI CORP

Concrete stirring device with adjustable mixing proportion

Owner:三亚神力混凝土有限公司

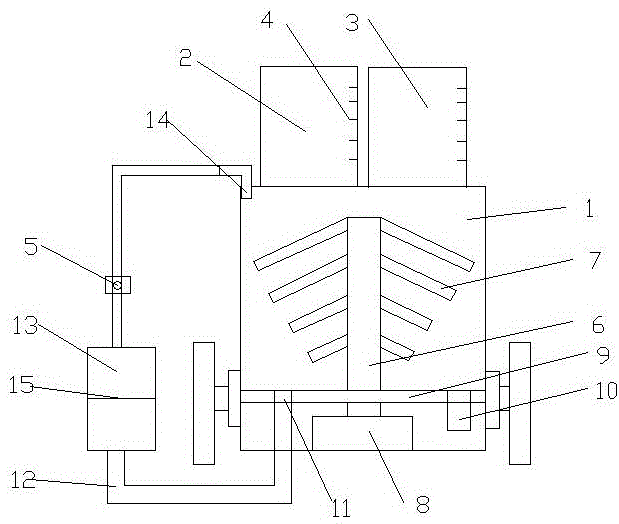

Separation type concrete mixer

The invention relates to a separation type concrete mixer which comprises a mixing bucket, a gravel aggregate bin, a water tank and a cement bin, and is characterized in that the bottoms of the gravel aggregate bin, the water tank and the cement bin lead to the mixing bucket; scales are arranged on the outer walls of the gravel aggregate bin, the water tank and the cement bin; a water inlet valve and a water outlet valve are arranged at the lower end of the water tank; a tilting sand sieving net is arranged at the upper part of the gravel aggregate bin; a coarse material outlet is formed in the gravel aggregate bin making contact with the lower part of the sand sieving net; a gravel inlet valve and a fine material outlet are arranged at the bottom of the wall of the gravel aggregate bin; a cement inlet valve and a cement outlet are arranged at the bottom of the cement bin. The separation type concrete mixer adopting the technical scheme can be used for satisfactorily controlling the concrete control quantity and screening gravels.

Owner:CHONGQING CHENGSHUO TECH

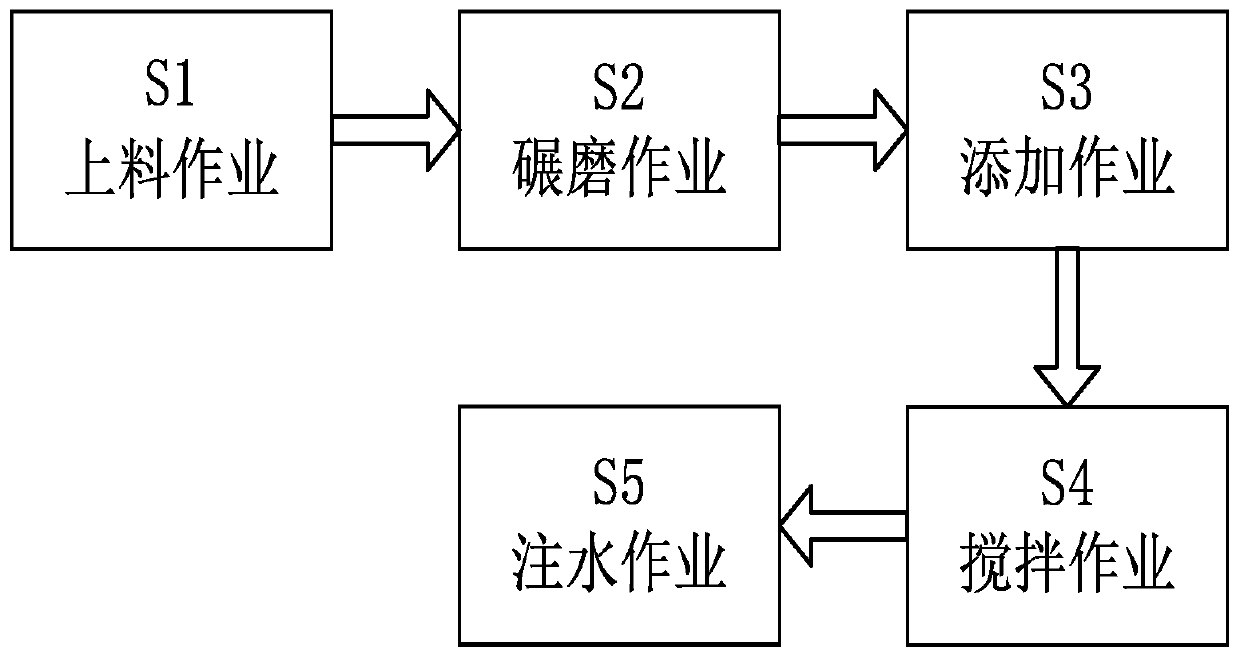

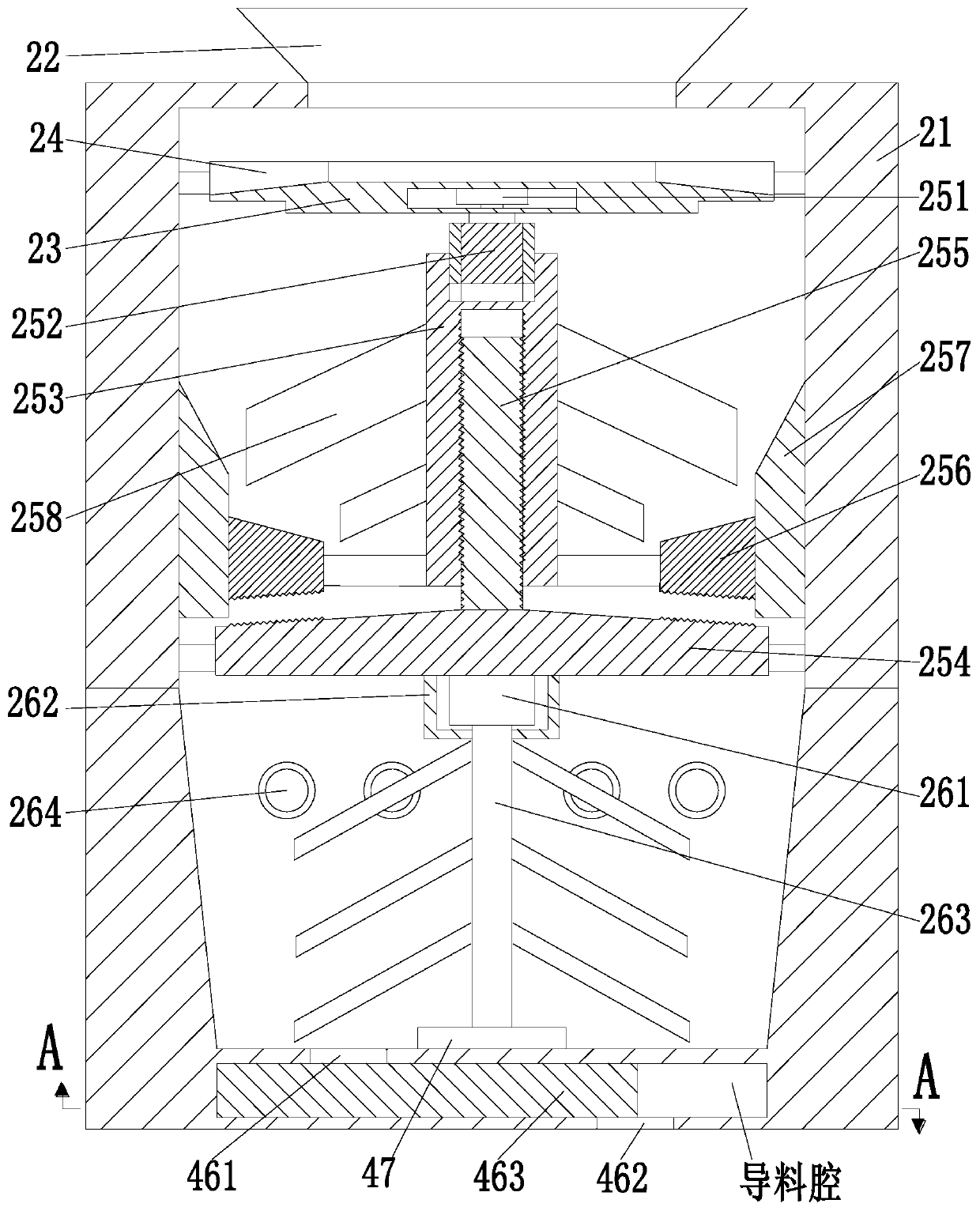

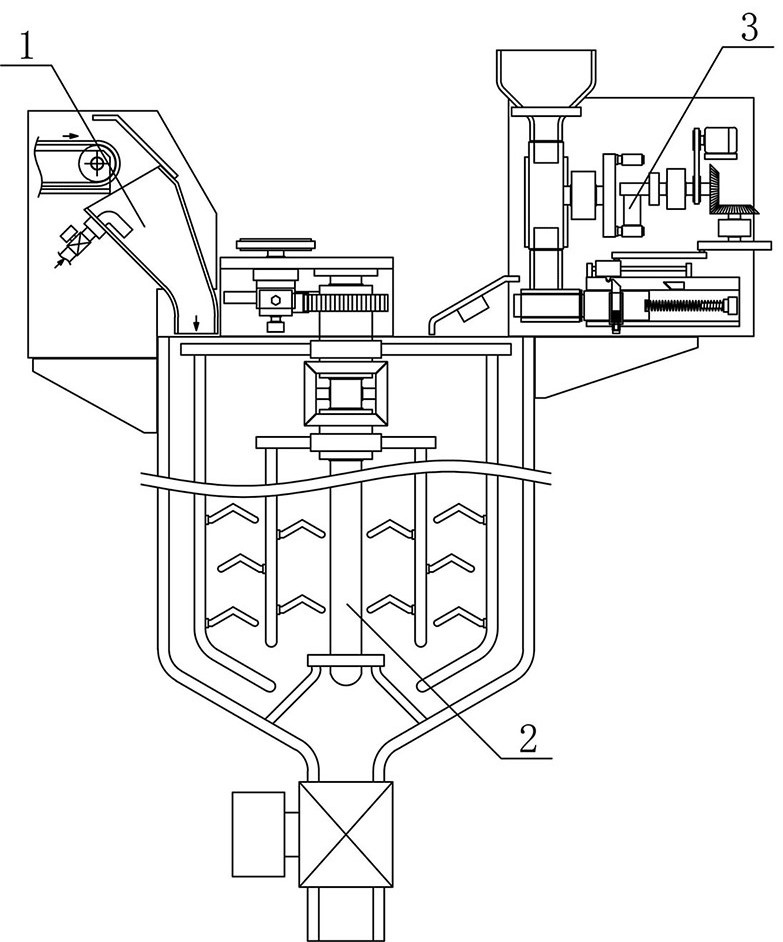

Hierarchical multi-grade type concrete mortar preparation material mixing treatment technology

ActiveCN111300643ASolve the strength problemSolve viscosityMixing operation control apparatusPretreatment controlMaterials scienceTreatment unit

The invention relates to a hierarchical multi-grade type concrete mortar preparation material mixing treatment technology adopting a concrete mortar preparing device. The concrete mortar preparing device comprises a mixing cylinder, a treatment unit, an additive cylinder and a water feeding unit. The treatment unit is arranged at the upper end of the mixing cylinder. The left end of the mixing cylinder is connected with the water feeding unit through a pipeline. The right end of the treatment unit is connected with the additive cylinder through a pipeline. By designing the pagoda type multi-grade structure of the material mixing device, the manner of feeding sand, stone and cement at the first grade, feeding various additives at the second grade, feeding water at the third grade is adopted, each step of the technology is treated in a separated manner, and then the problem that since residual additives and moisture can conduct a reaction with the sand, stone and cement earlier, the strength of the concrete is lowered is solved. According to the hierarchical multi-grade type concrete mortar preparation material mixing treatment technology, by feeding the mortar at a fixed quantity and then feeding water at a fixed volume, the problem that due to excessively fed water, the strength and viscosity of the concrete are influenced is solved.

Owner:江西萍乡南方建材有限公司

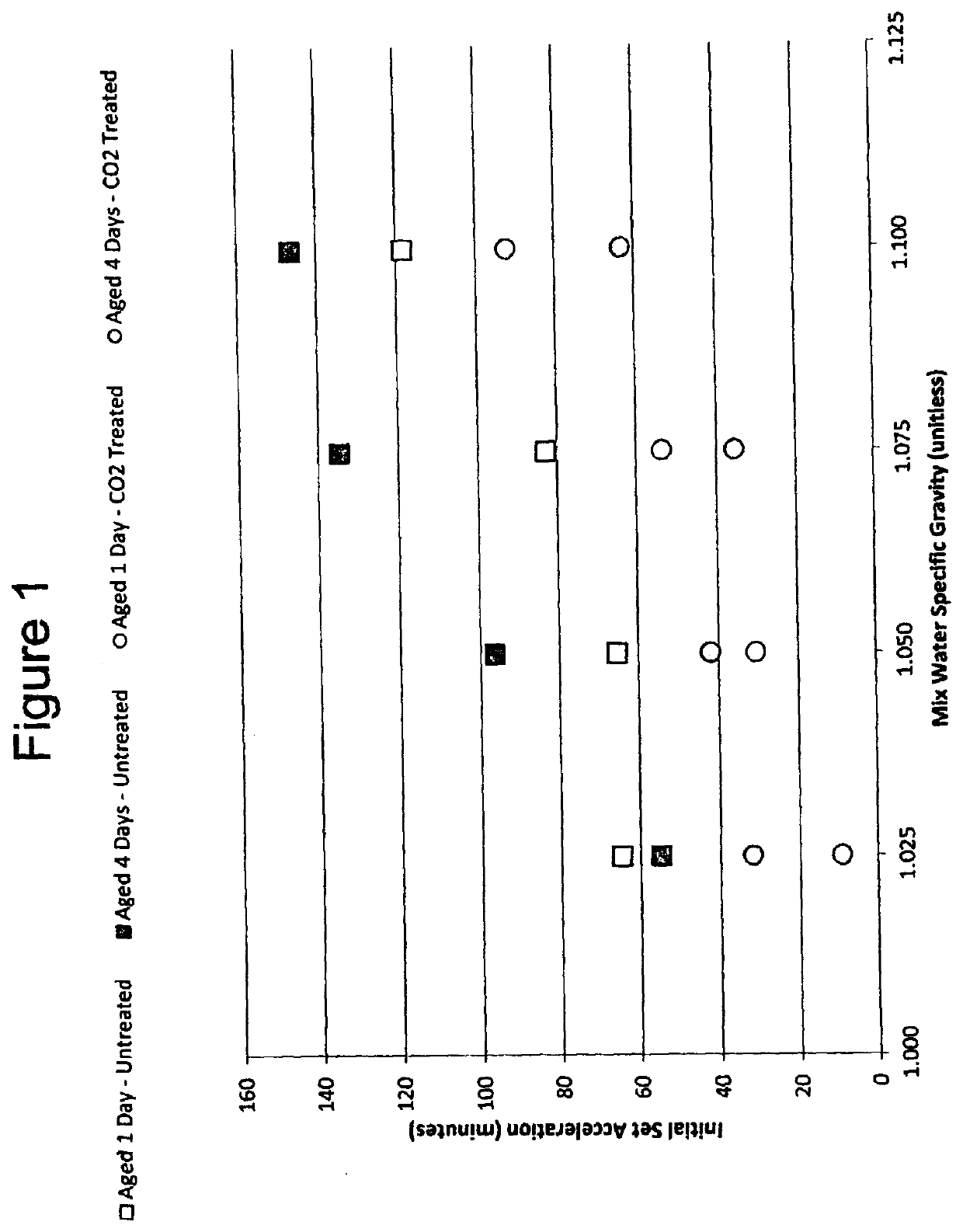

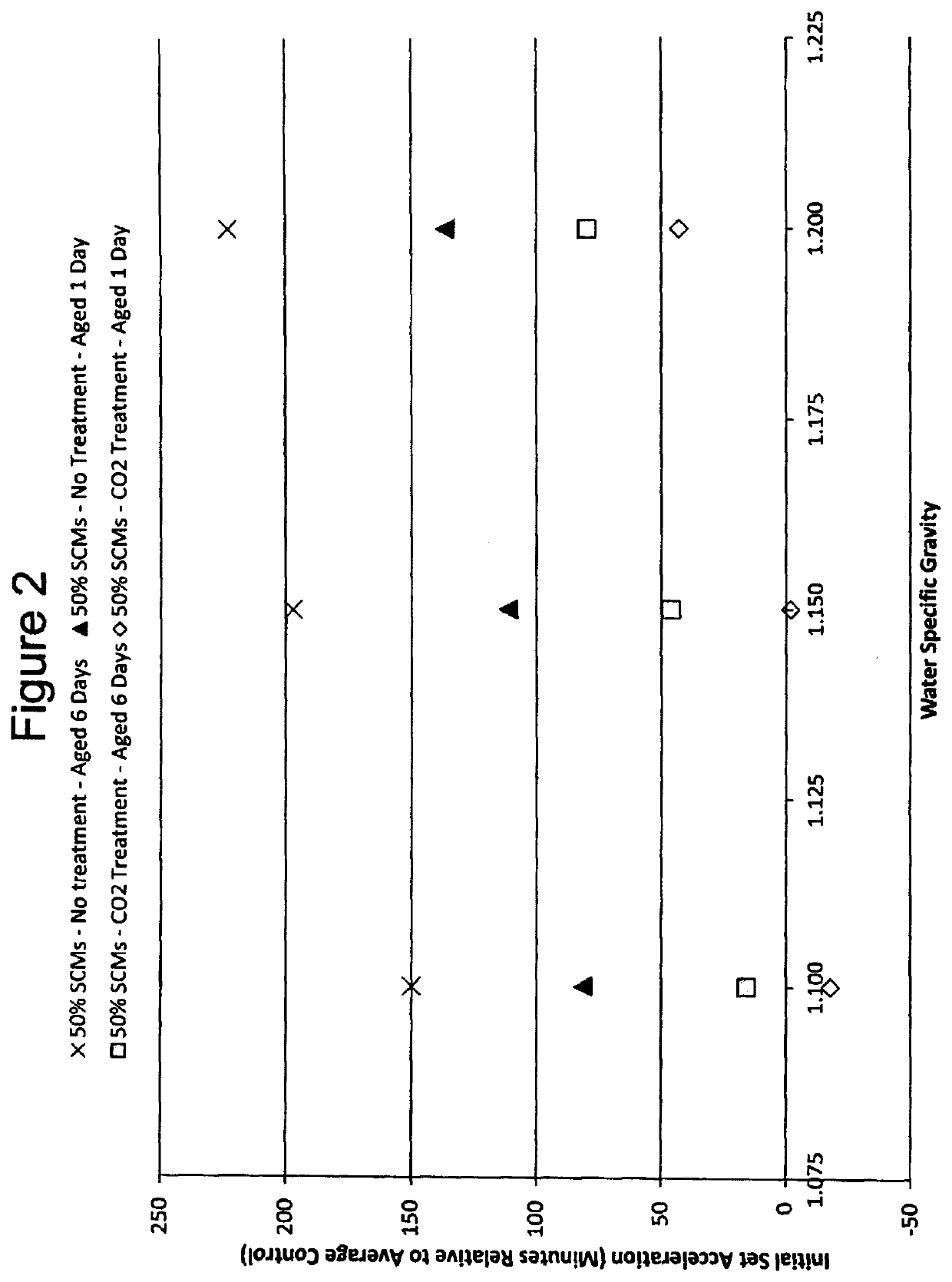

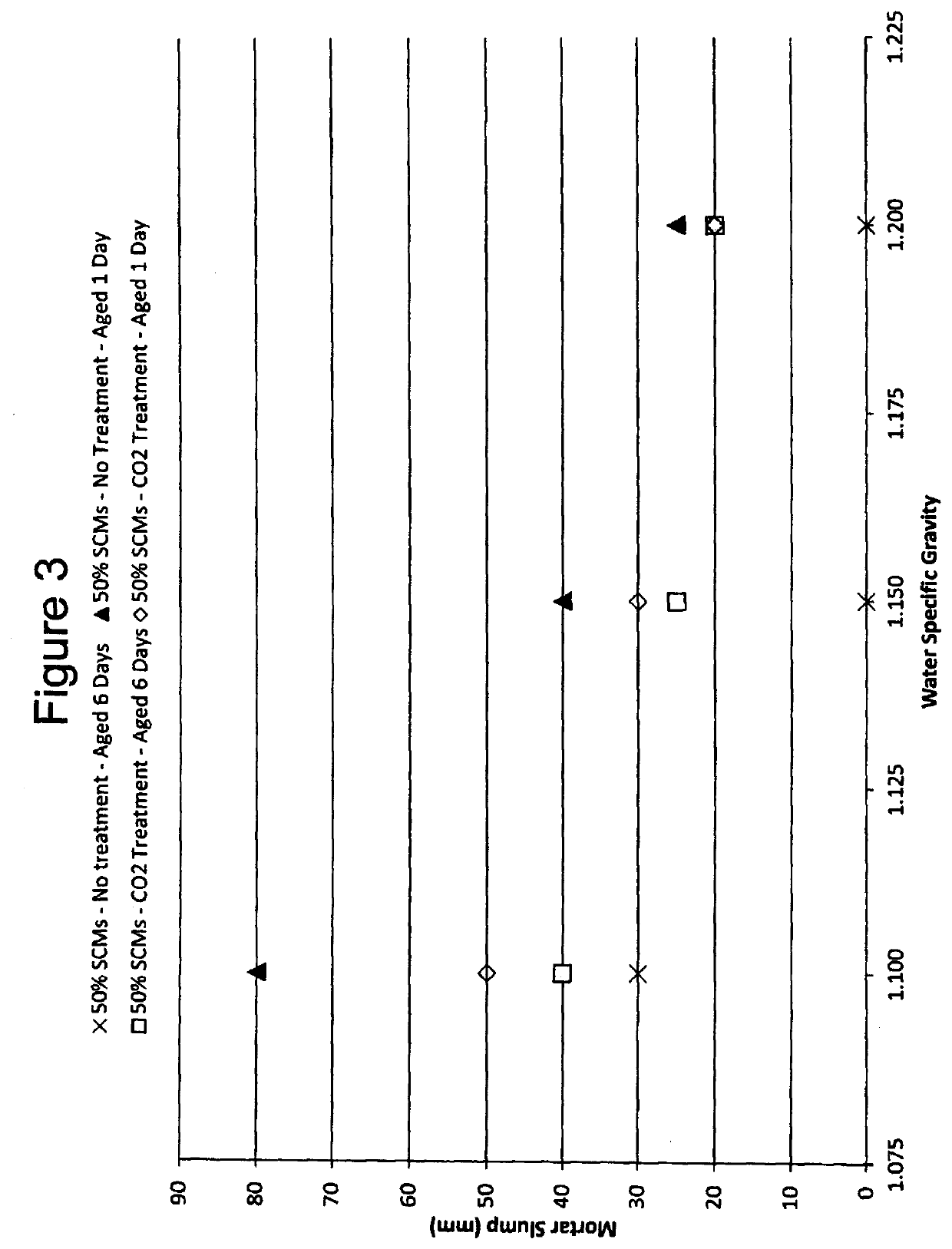

Methods and compositions for treatment of concrete wash water

PendingUS20200282595A1Water treatment parameter controlWaste water treatment from ceramic industriesWash waterEnvironmental engineering

The invention provides methods and compositions for treating wash water from concrete production with carbon dioxide. The treated wash water can be reused as mix water in fresh batches of concrete.

Owner:CARBONCURE TECH

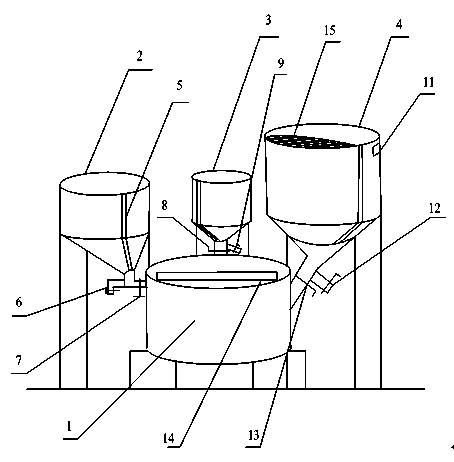

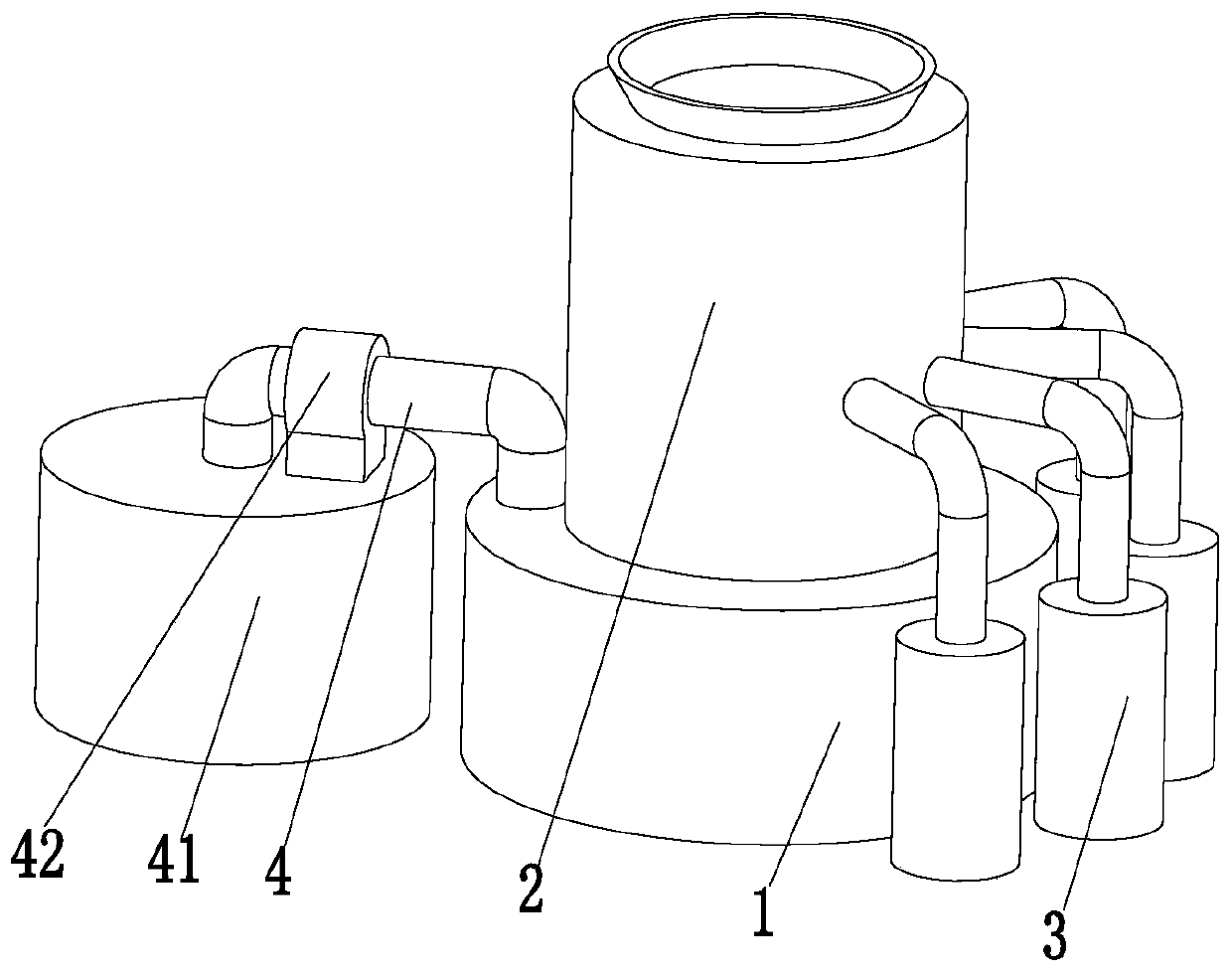

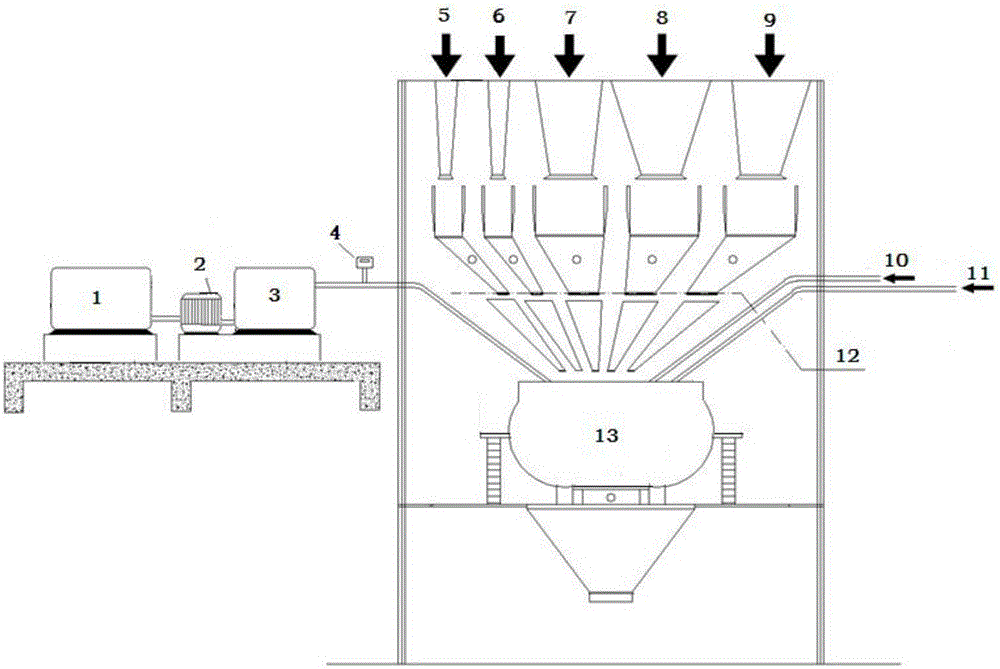

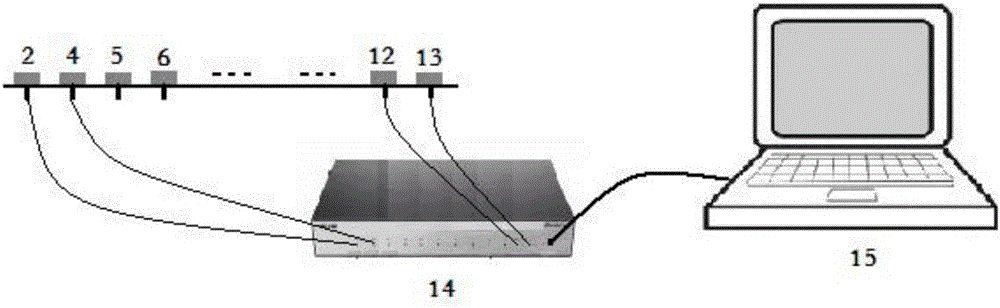

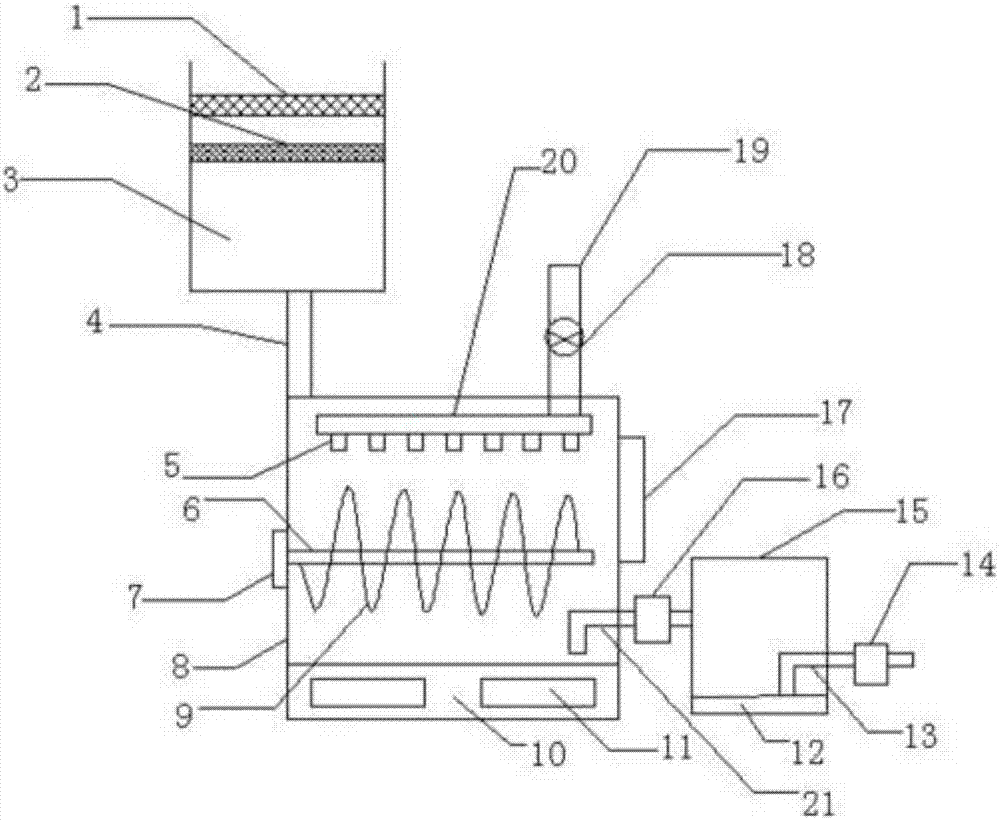

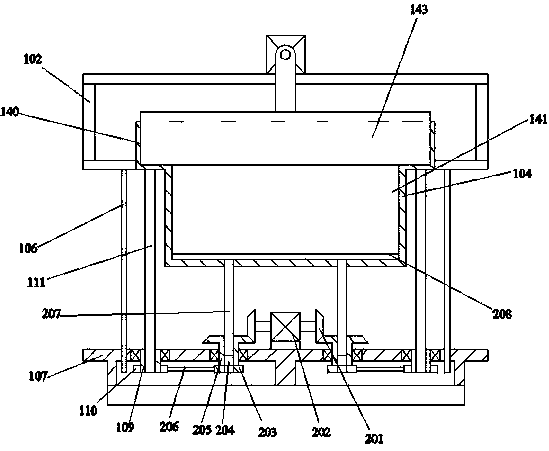

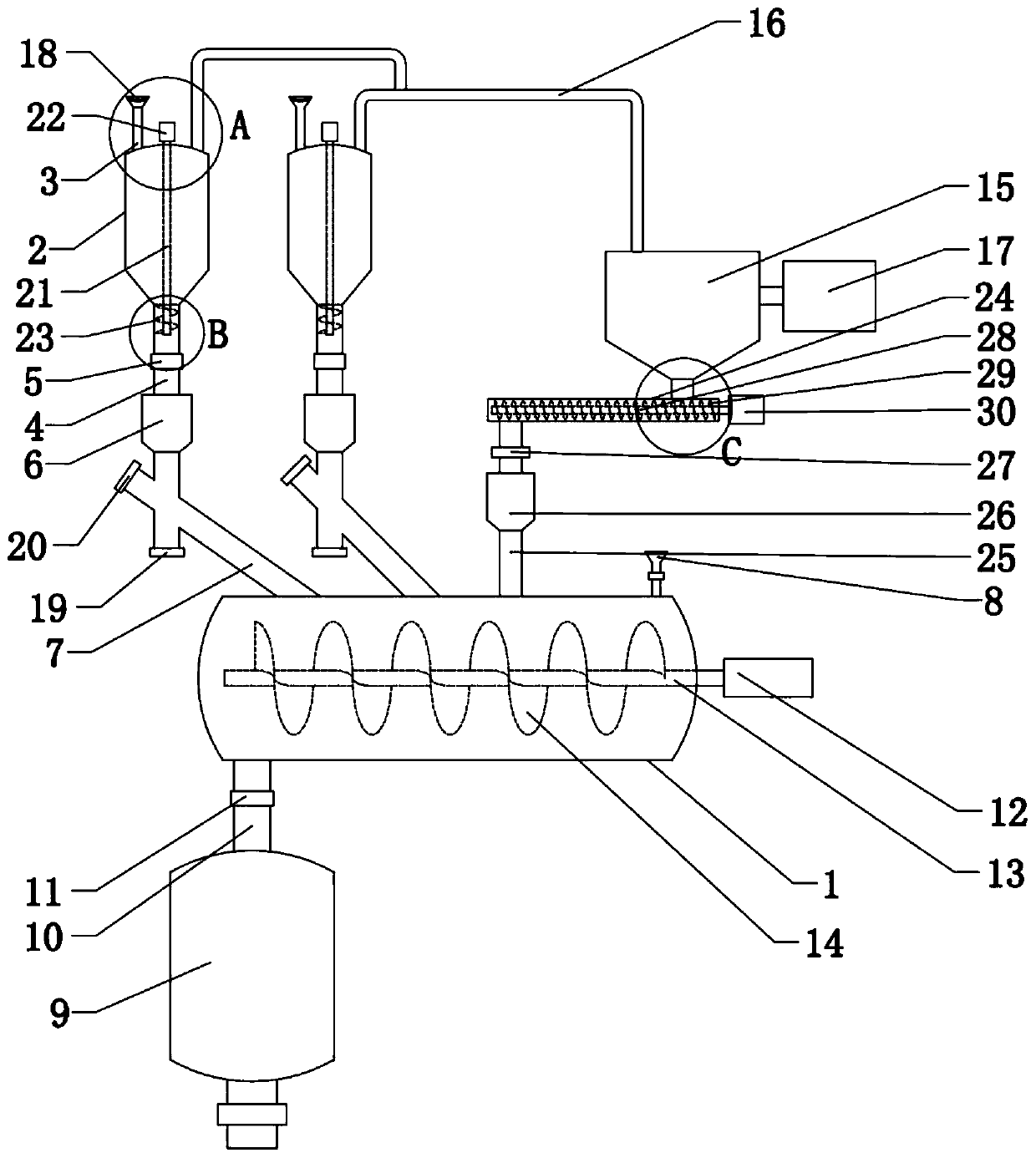

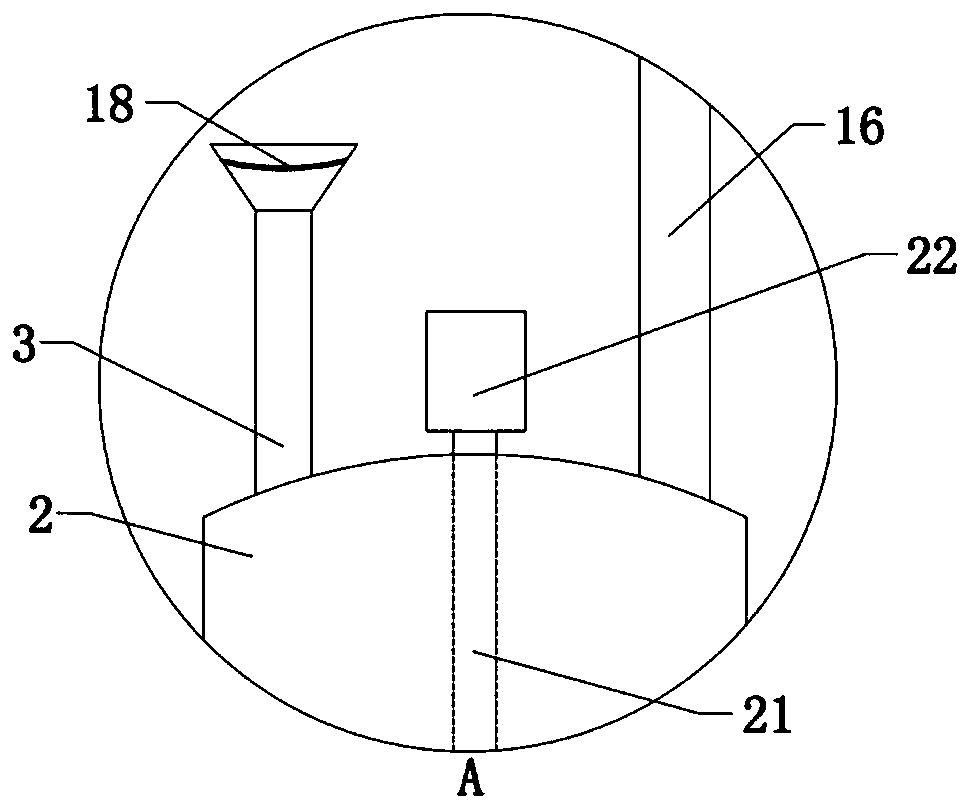

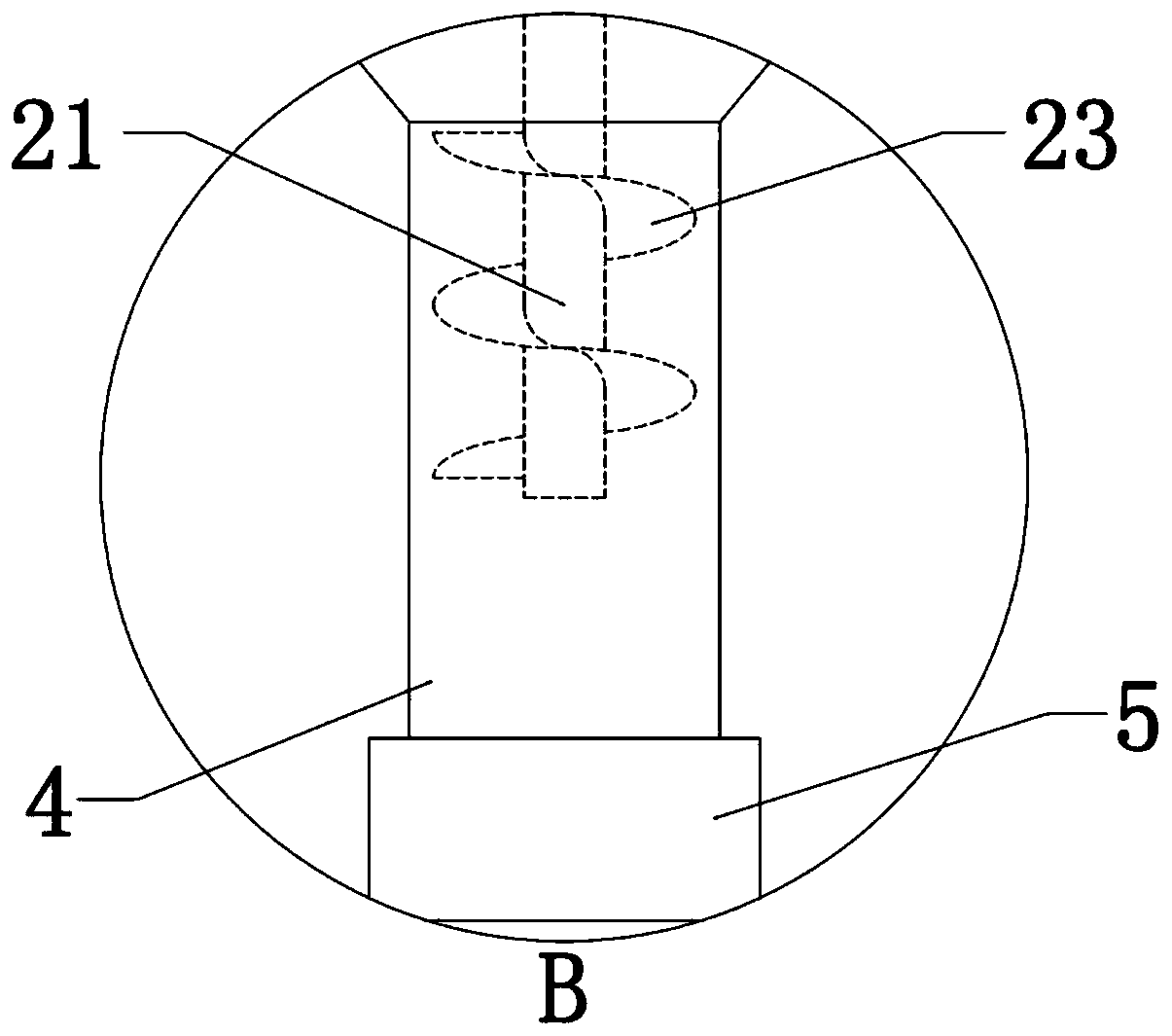

Lightweight concrete mixing device for subway vibration reduction and isolation road bed and mixing method for lightweight concrete mixing device

ActiveCN106182414ABlock and reduce transmissionMixing operation control apparatusPretreatment controlUltimate tensile strengthWater reducer

The invention discloses a lightweight concrete mixing device for a subway vibration reduction and isolation road bed and a mixing method for the lightweight concrete mixing device. In the device, an EPS storage cavern (1), a centrifugal machine (2), an EPS storage bin (3), a flow meter (4) and a mixing bin (13) are sequentially connected; a water feeding hole (5), a water reducer feeding hole (6), a cement feeding hole (7), a stone feeding hole (8) and a sand feeding hole (9) are separately connected to an upper hole of the mixing bin (13) through a weightometer (12); a thichener feeding hole (10) and a polymerizing agent feeding hole (11) are separately connected to the upper hole of the mixing bin (13); a control command generator (14) is connected to a computer (15) for separately controlling feeding of each part; and a discharge hole is formed in the lower part of the mixing bin (13). Strength and quality of lightweight concrete of the subway vibration reduction and isolation road bed are ensured, practical engineering construction needs are met, a development period of special equipment is shortened, and equipment operation and investment cost is reduced.

Owner:SOUTHEAST UNIV

Mortar treatment equipment

InactiveCN107972175AEasy to mix and handleSimple structureSievingGas current separationEngineeringMechanical engineering

The invention relates to the technical field of architecture, and provides to mortar treatment equipment. A quantitative weighing hopper communicates with a stir chamber through a mortar raw materialconveying pipeline. The quantitative weighing hopper is internally provided with a first vibration screen cloth device and a second vibration screen cloth device from top to bottom in sequence. The stir chamber is further connected with a water supplying pipeline. The water supplying pipeline is internally provided with an electric flow valve. The electric flow valve is in electric connection witha water quantity setting panel arranged at the exterior of the stir chamber. Multiple rotation water distribution devices are distributed evenly below a water distribution plate. The middle positionin the stir chamber is provided with a rotation shaft. The rotation shaft is provided with a stir paddle. The stir chamber communicates with a discharging weighing tube through a connecting pipeline.The connecting pipeline is provided with a connecting pump. The inner bottom of the discharging weighing tube is provided with a weight induction bottom plate. A mortar guiding out pipeline extends from the bottom of the discharging weighing tube to the exterior of the discharging weighing tube. The mortar guiding out pipeline is provided with a mortar guiding out pump. The mortar treatment equipment has the beneficial effects of being even in stir and capable of feeding and discharging quantificationally.

Owner:慈溪市舒润卫浴实业有限公司

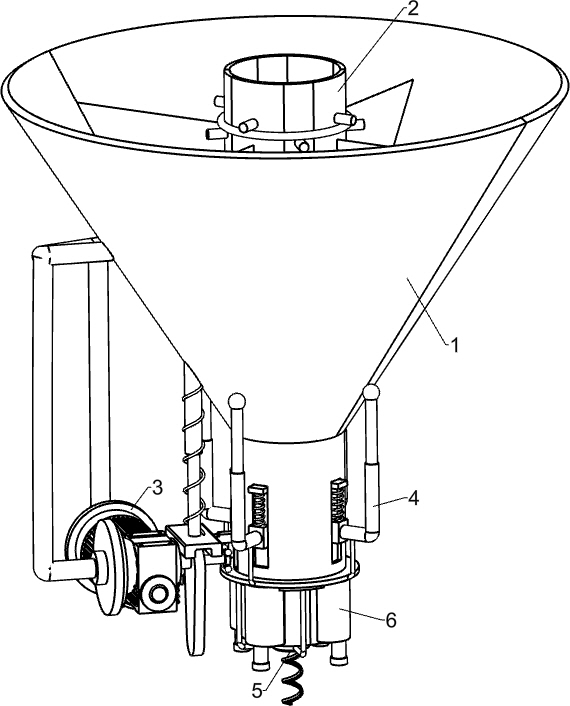

Powder adding device for concrete preparation

ActiveCN111775332AWell mixedQuality improvementMixing operation control apparatusLarge containersProcess engineeringMaterials science

The invention relates to a powder adding device, in particular to a powder adding device for concrete preparation. The powder adding device for concrete preparation is used to achieve the technical purposes that powder can be added quickly according to the proportions, and operation is convenient to carry out. The powder adding device for concrete preparation comprises a material storage hopper, amaterial isolation assembly and a feeding assembly, wherein the material isolation assembly is installed in the material storage hopper and is used to store multiple types of powder in an isolation manner, and the feeding assembly is installed on the material storage hopper and carries out feeding in a vertical sliding manner. According to the powder adding device, multiple types of powder can beplaced separately because of the material isolation assembly; powder can be output intermittently because of the feeding assembly so that the powder can be mixed better, and the quality of prepared concrete is improved; and because the space of a feeding pipe can be customized according to the feeding quantity of the powder, quantification can be quickly carried out, and equipment can be more convenient to use.

Owner:儋州泰达实业有限公司

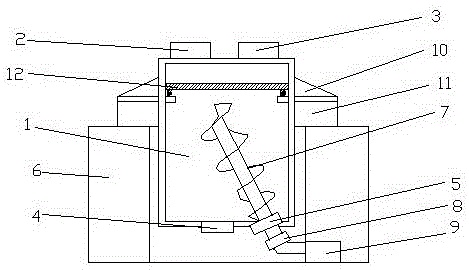

Improved concrete mixer

InactiveCN106476139AImprove product qualityReasonable structureMixing operation control apparatusCement mixing apparatusEngineeringMixing effect

The invention relates to a concrete mixer, and belongs to the technical field of construction machinery. The technical scheme of the invention is characterized in that the improved concrete mixer includes a mixing box; a feed box and a water inlet tank are arranged at both sides on the mixing box and are all made of transparent materials; surfaces of the feed box and the water inlet tank are all provided with graduation lines; a stirrer is arranged in the mixing box and includes a stirring shaft arranged in the internal center of the mixing box and stirring vanes arranged on the stirring shaft; the stirring vane gradually decreases from top to bottom; a driver is arranged at the bottom of the stirring shaft; a separation plate is arranged between the stirrer and the driver and is provided with a discharge port and a water outlet; and the water outlet is connected with a water outlet pipe, and the water outlet pipe is connected with a purifying water tank which is arranged at the exterior of the mixing box. The improved mixer has reasonable structure and good mixing effect, and is favorable for improving product quality and working efficiency.

Owner:王亚萍

Improved concrete mixer

InactiveCN106476140AAvoid knotsReasonable structureMixing operation control apparatusCement mixing apparatusChemical engineering

The invention relates to a concrete mixer and belongs to the field of building construction equipment. The improved concrete mixer comprises a stirring box and a support for supporting the stirring box. The stirring box is arranged in the cavity of the support. A stirring shaft is arranged in the stirring box. The top of the stirring box is provided with a material inlet and a water inlet. The bottom of the stirring box is provided with a material outlet. One side of the material outlet is provided with an inclined bearing board. The stirring shaft is fixed on the bearing board and obliquely stretches into the stirring box. The rear end of the stirring shaft is provided with a rotation driving device, the rotation driving device is connected to a motor, support lugs are symmetrically arranged on two external sides of the upper part of the stirring box, and a weighing device is arranged between each one support lug and the support. The provided concrete mixer has a reasonable structure. Due to the obliquely arranged stirring shaft, the discharging of concrete is uniform and quick. The agglomeration of concrete is avoided. The weighing devices arranged between support lugs and the support can improve the accuracy of weighing.

Owner:李天兵

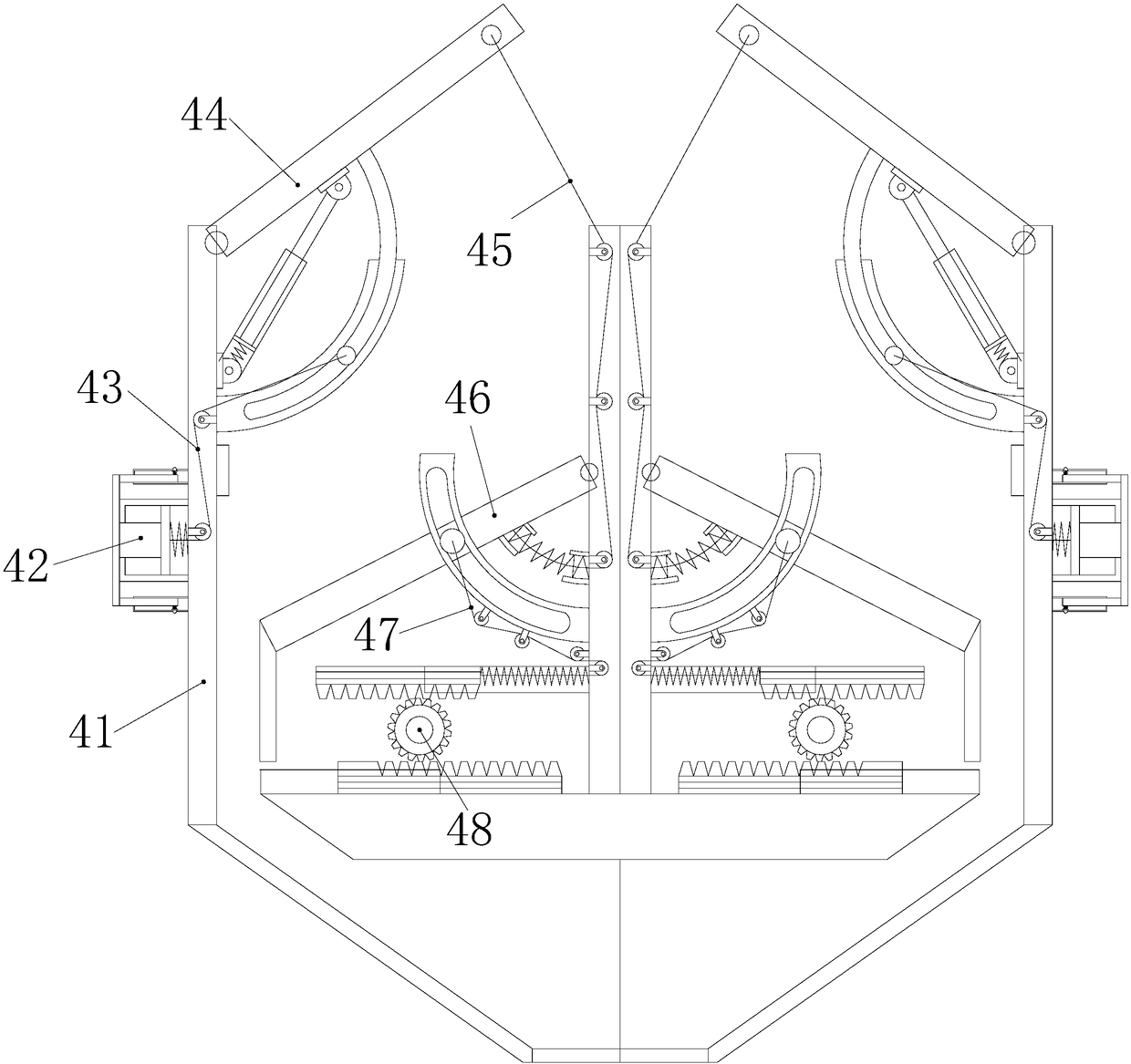

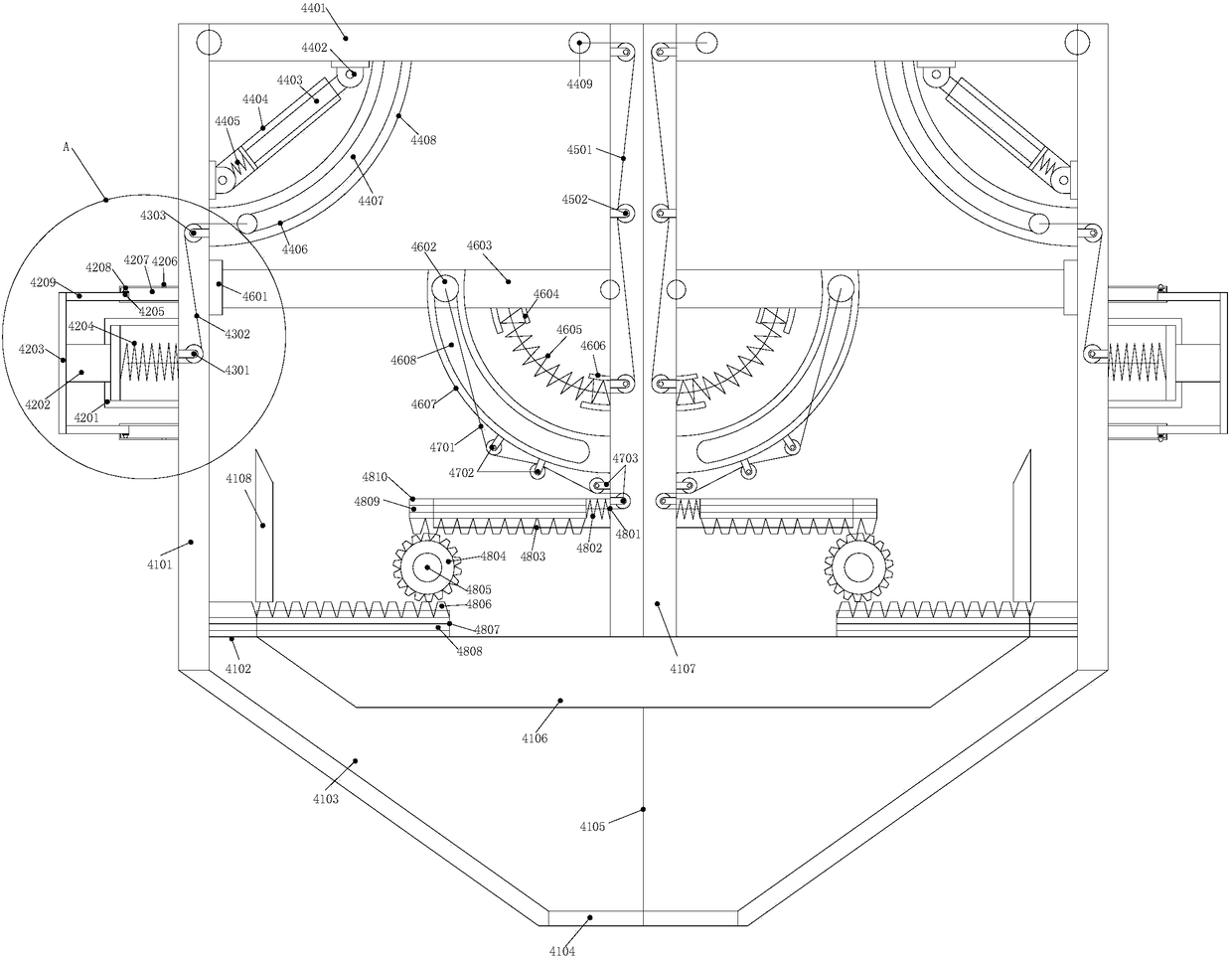

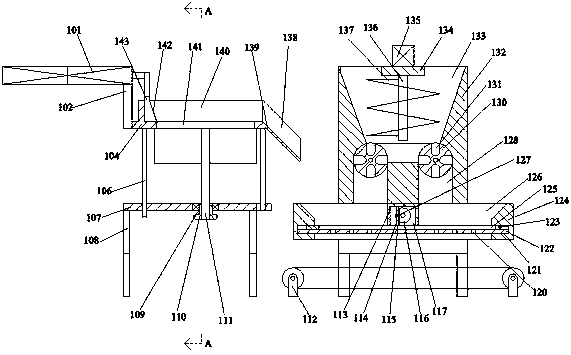

Concrete preparation equipment

ActiveCN110497526ACut costsSave floor spaceMixing operation control apparatusPretreatment controlEngineeringActual use

The invention discloses concrete preparation equipment which comprises a sand dumping device for dumping sand quantatively. A pebble dumping device for dumping pebbles quantatively is arranged on theright side of the sand dumping device, a screening device for screening specifications of the pebbles is arranged on the lower side of the pebble dumping device, a conveyor for discharging sand and the pebbles out of an external space is arranged on the lower side of the screening device, and the conveyor is driven by a motor to rotate. The equipment adopting the sand dumping device, the pebble dumping device and the pebble screening device can achieve a large batch sand dumping process on the premise of saving equipment space and can screen the pebbles, so that a condition that actual use ofconcrete which is manufactured by the pebbles which do not meet the specifications is affected is avoided.

Owner:东至县龙腾商砼有限公司

Volumetric solid and liquid dispenser

InactiveUS6905048B2Accurate and efficient measurementControlling ratio of multiple fluid flowsMixing operation control apparatusMaterial supplyWaste management

A volumetric solid and liquid dispenser includes a drum sized for receiving and containing a predetermined volume of solid material from a solid material supply source. The supply source can be a hopper positioned above the drum. The drum is rotatably mounted to a support frame and can be rotated from a position in which it receives solid material from the supply source to a dispensing position in which it dispenses the solid material into a receptacle below. A liquid metering and dispensing container dispenses a predetermined volume of liquid into the receptacle for mixing with the solid material. The invention is particularly useful for dispensing predetermined volumes of sand and water into a cement mixer for mixing with mortar.

Owner:HARRIS ARCHIE J

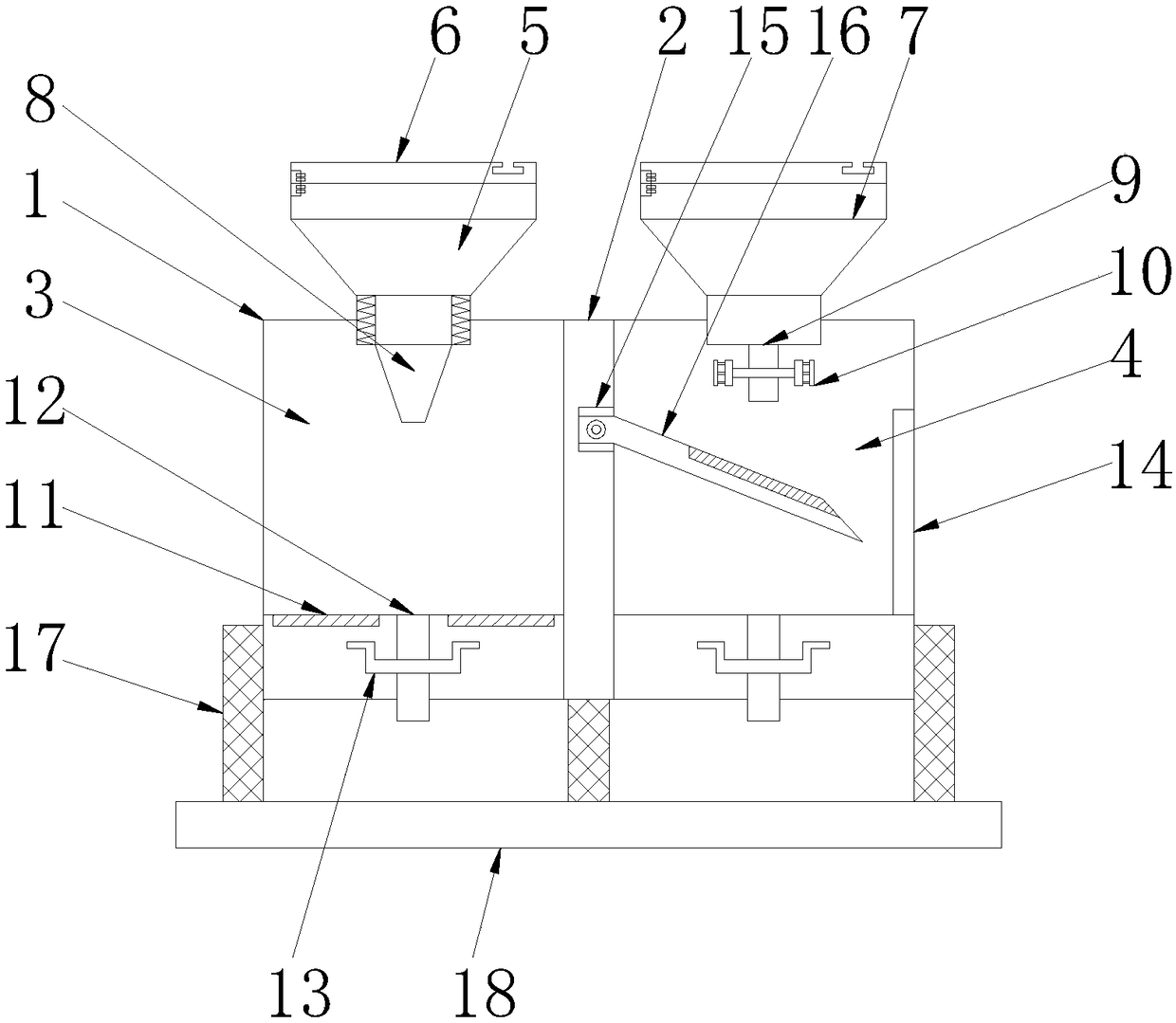

Metering hopper for concrete mixing station

InactiveCN108908735AEffective separationAvoid mixingMixing operation control apparatusVolumetric measuring devicesLiquid stateEngineering

The invention discloses a metering hopper for a concrete mixing station. The metering hopper comprises a box body, wherein a separation plate is arranged in the center of the box body; a solid state cavity is arranged at the left side of the separation plate; a solid state feeding hopper is arranged above the solid state cavity; the outer wall of the upper side of the solid state feeding hopper isconnected with a hopper cover through a hinge; a solution feeding hopper is arranged above a solution cavity; the outer wall of the solution feeding hopper is connected with the hopper cover througha hinge; a feeding guide pipe is arranged at the bottom of the solid state feeding hopper; a water pipe is arranged at the bottom of the solution feeding hopper. Through the arrangement of the solid state cavity and the solution cavity, in the concrete mixing station, common raw materials are in a solid state, a liquid state and a dust shape; during the metering, the separated metering is used, sothat the normal use incapability since the concrete takes effect in advance caused by reaction through mixing is avoided; the solid state cavity and the solution cavity are installed, so that solid state dust and liquid state raw materials are effectively separated; the occurrence of mixing phenomenon is avoided.

Owner:芜湖佩林郁松计量科技有限公司

Hopper with measuring guide

Owner:SCISM JOHN A

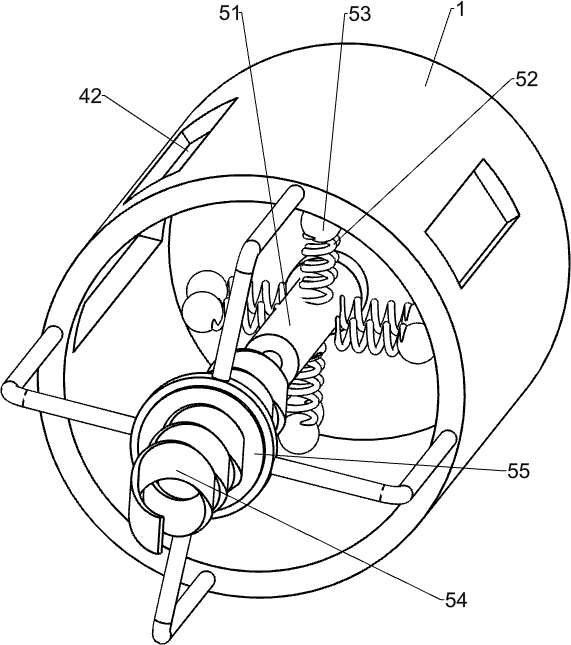

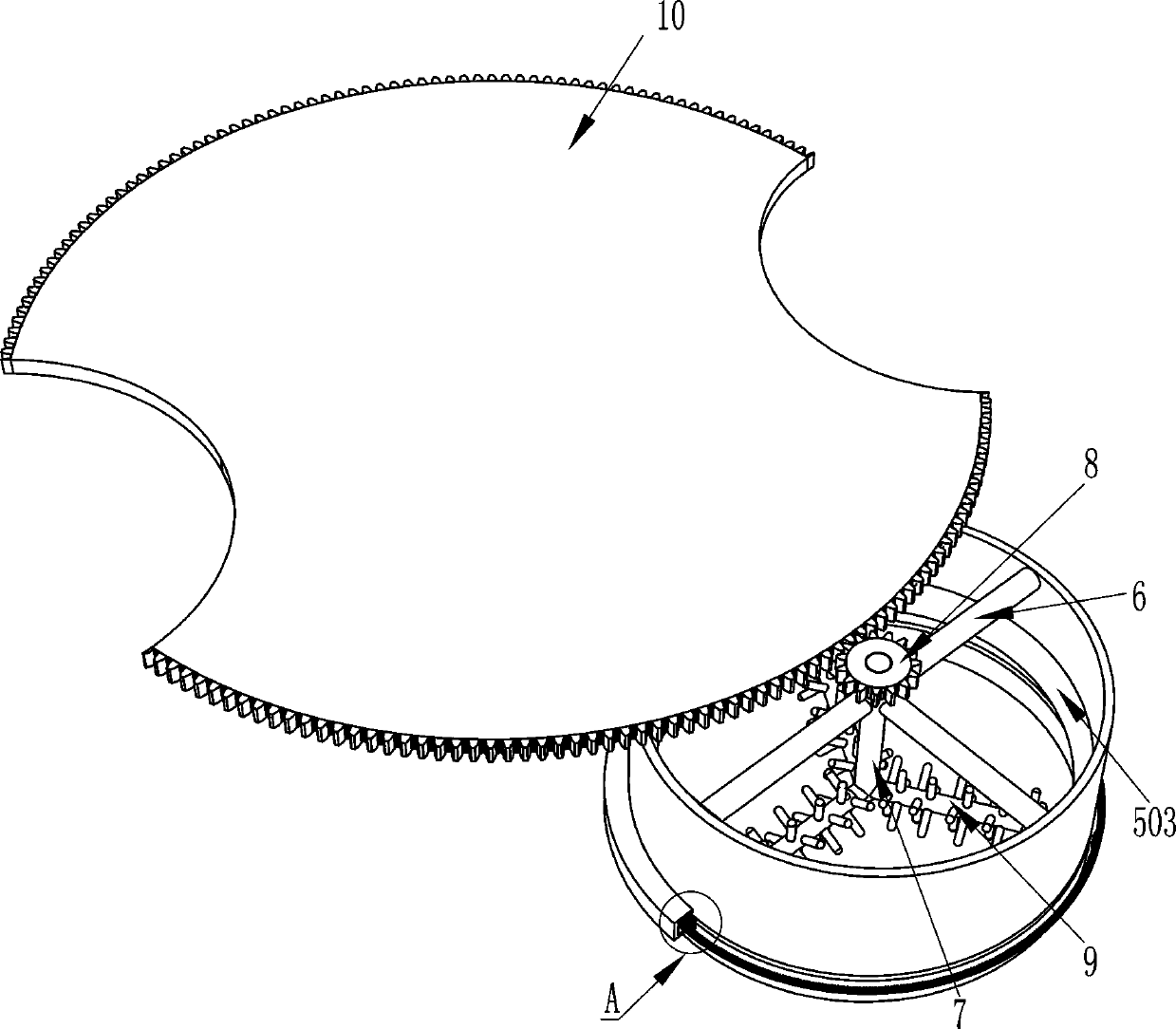

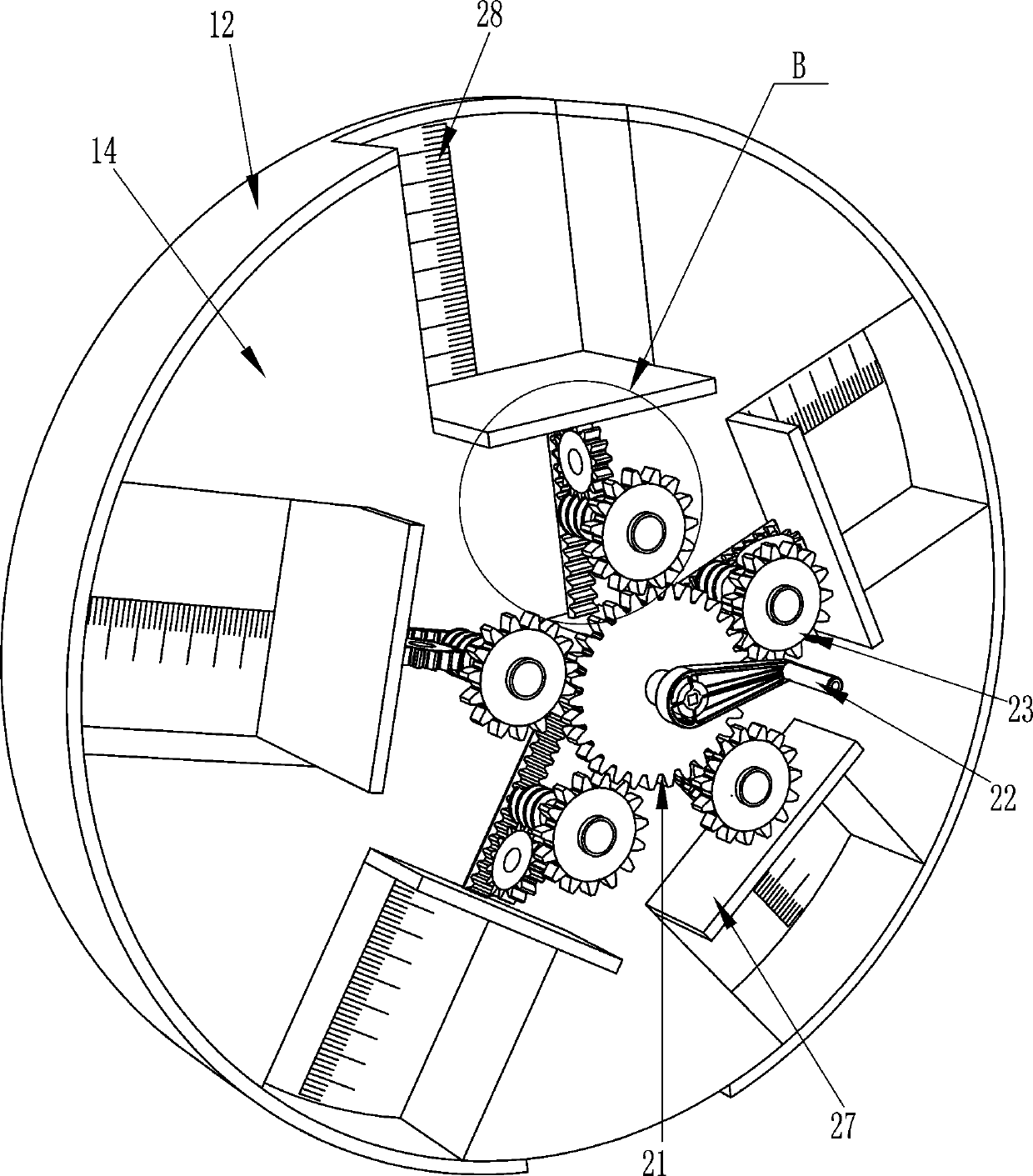

Synchronous discharging equipment for various raw materials for ceramsite production

ActiveCN111168841AWell mixedDoes not affect normal useDischarging apparatusMixing operation control apparatusElectric machineryIndustrial engineering

The invention relates to synchronous discharging equipment, in particular to synchronous discharging equipment for various raw materials for ceramsite production. The technical problem is how to design the synchronous discharging device for the various raw materials for ceramsite production, which can replace manual mixing, is simple and convenient to operate and has high working efficiency. The synchronous discharging equipment for the various raw materials for ceramsite production comprises a rack, a motor, a first rotating shaft, a transmission device, a first rotating disc, annular discs,a stirring mechanism and the like; the first rotating shaft is rotationally connected to the center of the circle at the top of the rack, the first rotating disc is fixedly connected to the top end ofthe first rotating shaft, and the five annular discs are fixedly connected to the outer side surface of the first rotating disc at intervals circumferentially. By starting the motor, second rotatingdiscs can drive grooves to rotate, the grooves enable equal amounts of raw materials to fall into the annular discs, stirring rods rotate to stir and mix the raw materials, manual stirring and mixingof the raw materials are not needed, the operation is easy and convenient, and the working efficiency is improved.

Owner:江苏海颜新材料有限公司

Production device for dry-mixed mortar

PendingCN110788991AEasy to control delivery speedReduce flow rateDischarging apparatusMixing operation control apparatusProcess engineeringButterfly valve

The invention relates to a production device for dry-mixed mortar. The production device for the dry-mixed mortar comprises a mixing tank, wherein a plurality of raw material storage and weighing devices are arranged above the mixing tank; each raw material storage and weighing device comprises a raw material tank; a pouring pipe and a first raw material conveying pipe are arranged on the raw material tank; a first pneumatic butterfly valve and a raw material weighing tank are sequentially arranged on the first raw material conveying pipe; the first raw material conveying pipe and the mixing tank are communicated with a second raw material conveying pipe; an included angle between the second raw material conveying pipe and the first raw material conveying pipe is 30-60 degrees; the junction of the second raw material conveying pipe and the first raw material conveying pipe is located between the bottom end of the first raw material conveying pipe and the raw material weighing tank; a mixing device is arranged on the mixing tank; an accessory material pouring pipe is arranged on the mixing tank; a finished material tank is arranged below the mixing tank; and a second pneumatic butterfly valve is arranged on a finished material conveying pipe. The durability of a solid raw material conveying pipeline is improved; and the production device for the dry-mixed mortar is convenient touse, and wide in market prospect.

Owner:开封市筑帮商品砂浆有限公司

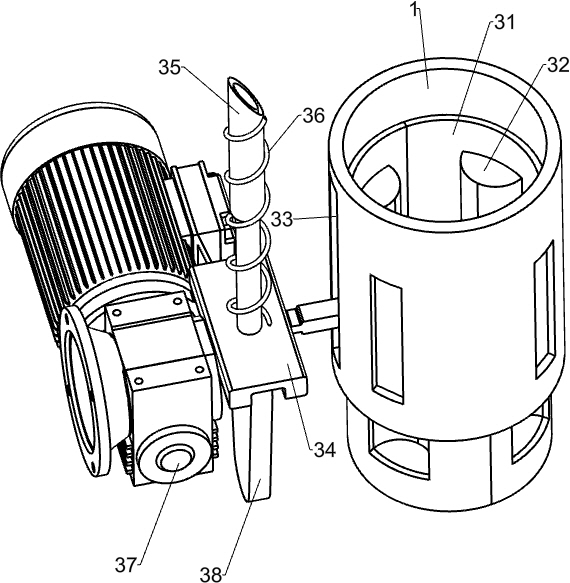

Processing system for steel pipe filled concrete

ActiveCN112356278AEfficient productionReasonable structural designMixing operation control apparatusCement mixing apparatusCircular discArchitectural engineering

The invention discloses a processing system for steel pipe filled concrete, and belongs to the field of building material processing mechanical equipment. A main material conveying mechanism and an auxiliary material filling mechanism are arranged on the two sides of the upper portion of a processing stirring mechanism, a stirring driving mechanism of the processing stirring mechanism is fixedly arranged on the upper side of a preparation stirring tank, processing outer stirring rods are arranged on the lower sides of the outer ends of a plurality of outer stirring supporting connecting plateson the outer side of an outer stirring fixing sleeve, processing inner stirring rods are vertically and fixedly arranged on the lower sides of the outer ends of a plurality of inner stirring supporting connecting plates on the outer side of an inner stirring fixing sleeve, a feeding guide pipe is arranged on a main material conveying support, auxiliary material storage grooves are formed in the two sides of a guide rotating disc respectively, and an auxiliary material pushing mechanism is arranged on an auxiliary material guide support on the adjacent side of an auxiliary material filling guide pipe. The processing system for steel pipe filled concrete is reasonable in structural design, can be used for quickly and efficiently producing and preparing the steel pipe filled concrete, can beused for conveniently and accurately adding production auxiliary materials as required, is high in processing automation degree and meets the requirements of production and use.

Owner:桐乡市钟大建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com