Synchronous discharging equipment for various raw materials for ceramsite production

A technology of raw materials and ceramsite, which is applied in the field of synchronous discharge equipment for various raw materials used in ceramsite production, can solve problems such as troublesome operation and low work efficiency, and achieve the effect of easy operation and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

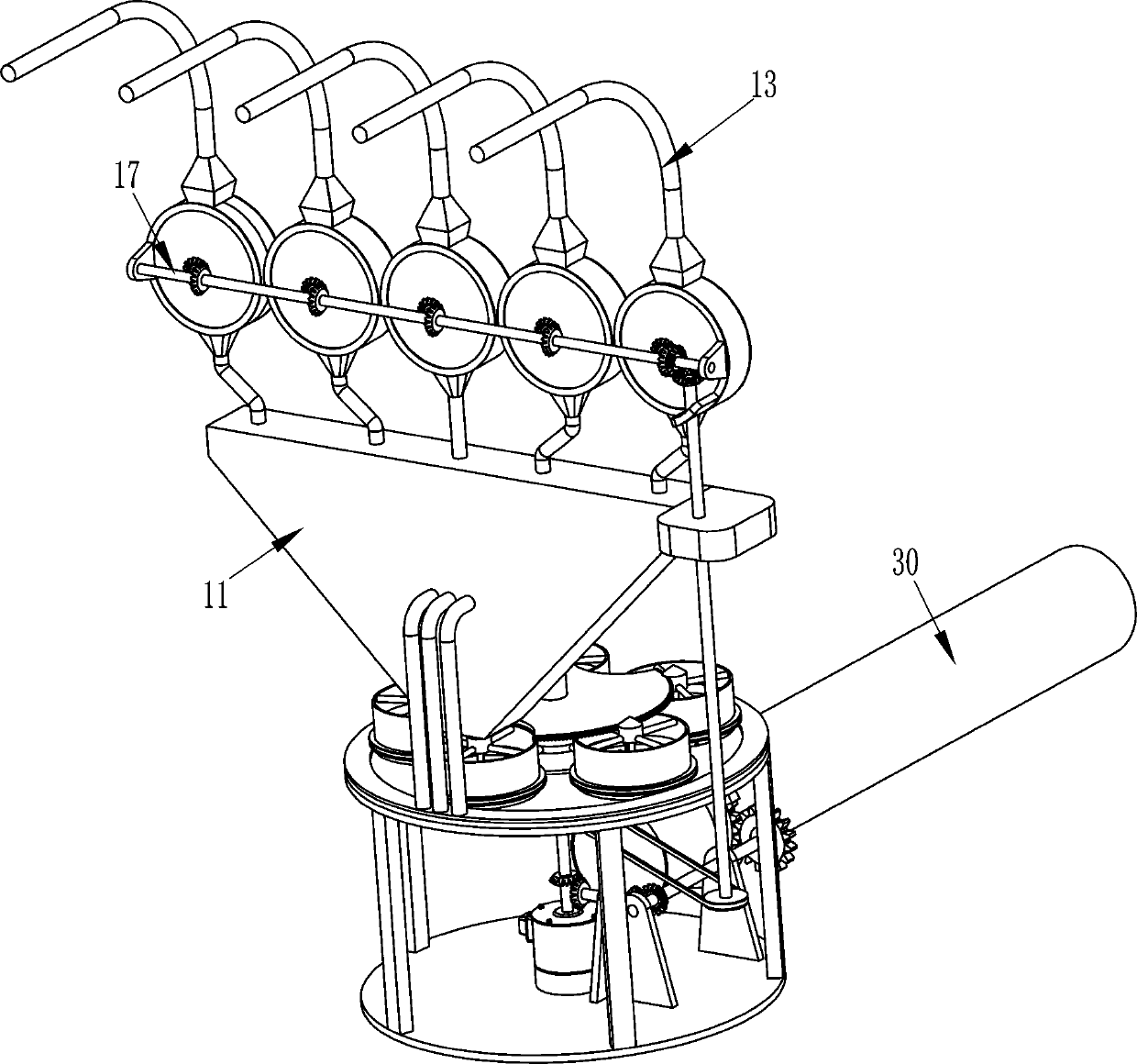

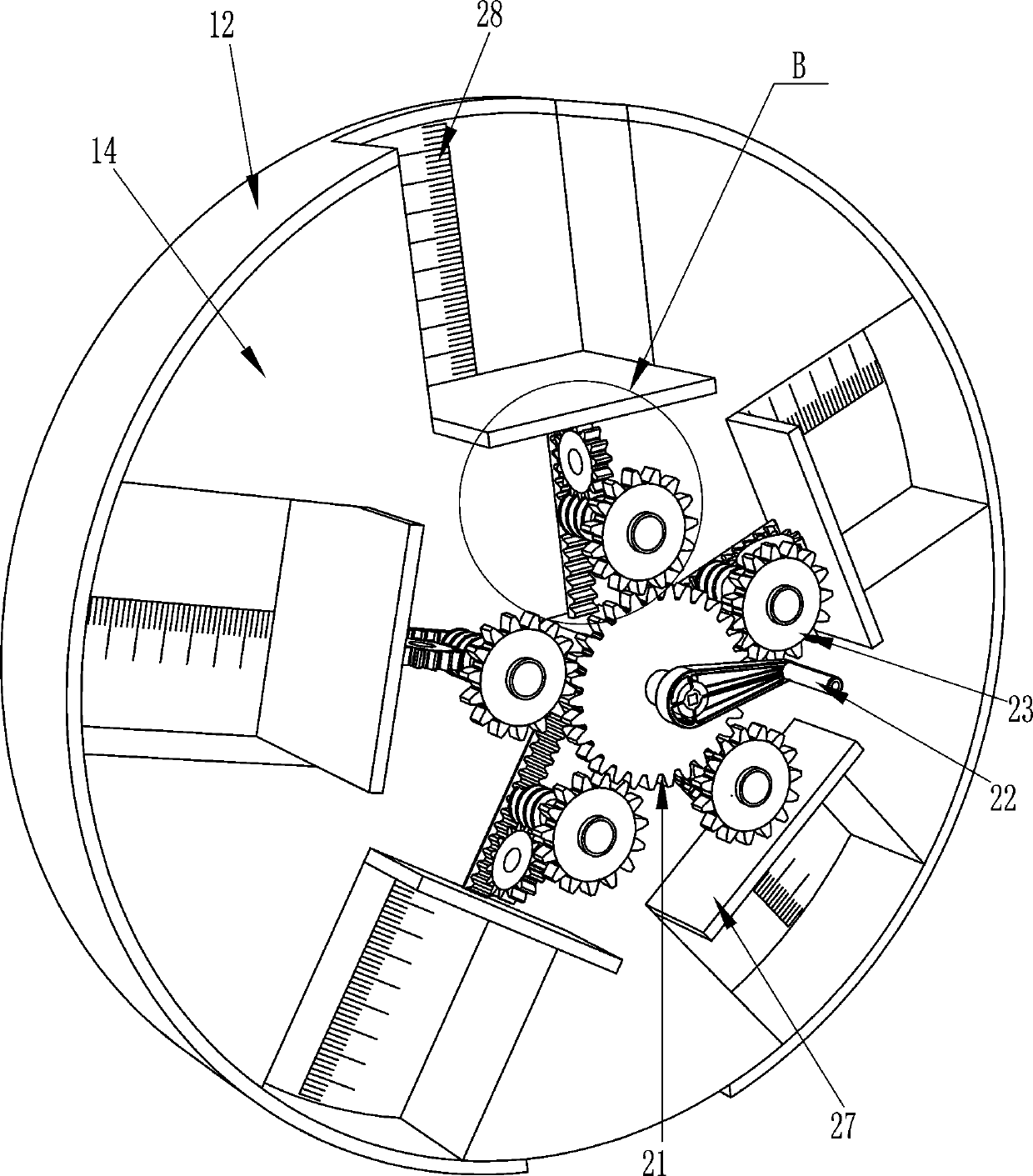

[0027] see Figure 1-Figure 8, a kind of synchronous discharge equipment for various raw materials used in the production of ceramsite, including a frame 1, a motor 2, a first rotating shaft 201, a transmission device 3, a first rotating disk 4, an annular disk 5, an agitating mechanism, a mixing box 11, The guide frame 12, the steel pipe 13, the second turntable 14, the transmission mechanism and the adjustment mechanism, the first rotating shaft 201 is rotatably connected to the center position of the top of the frame 1, the top of the first rotating shaft 201 is fixedly connected with the first turntable 4, and the first turntable 4 There are five annular discs 5 fixedly connected to the outer surface at evenly spaced intervals in the circumferential direction. The annular discs 5 are in contact with the top of the frame 1. There is a stirring mechanism inside the annular disc 5. The motor 2 is installed at the center of the inner bottom of the frame 1. The motor The output...

Embodiment 2

[0036] see figure 1 , 2 , 3, 9 and 10, the present embodiment is relative to embodiment 1, and the main difference is that in the present embodiment, it also includes a guide ring barrel 29, a cylindrical sleeve 30, a drum 31, a helical blade 32, the fifth gear 33, the fifth Straight bevel gear 34, the fifth shaft 35, the sixth gear 36 and the sixth shaft 37, the top front side of the frame 1 is connected with a guide ring barrel 29, the guide ring barrel 29 communicates with the discharge port 101, and the guide ring barrel 29 The front end is connected with a cylindrical sleeve 30, and the cylindrical sleeve 30 is connected with a drum 31 in a rotating manner. The inner wall of the drum 31 is equipped with a helical blade 32, and the left side of the outer surface of the drum 31 is fixed with a fifth gear 33, and the fifth gear 33 runs through the cylindrical sleeve. 30, the left rear part, the bottom of the frame 1 is connected with the fifth rotating shaft 35 in the left ...

Embodiment 3

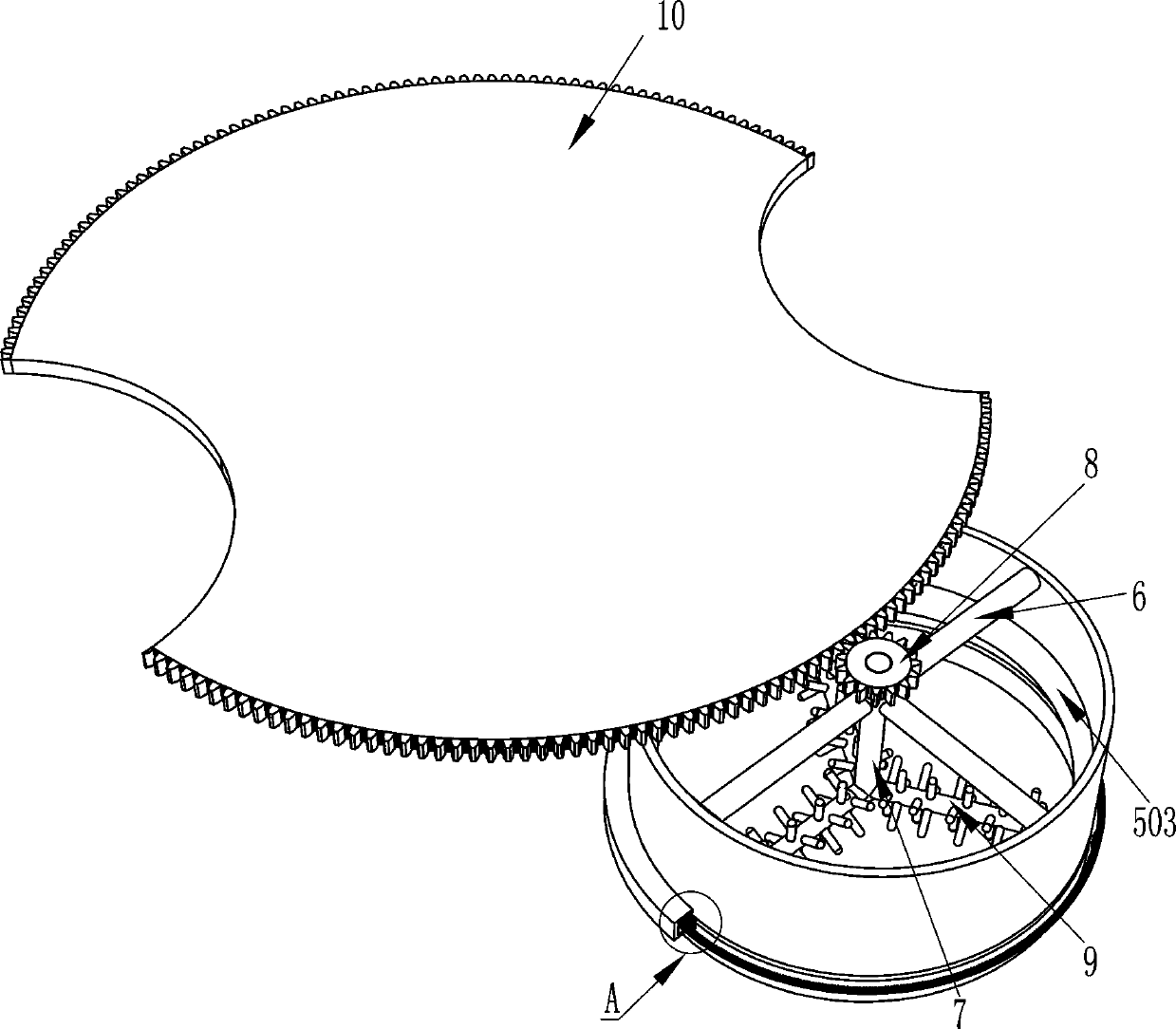

[0039] see Figure 4 and Figure 7 , the main difference between this embodiment and embodiment 1 and embodiment 2 is that in this embodiment, a wedge-shaped block 503 is also included. Gear 501 above.

[0040] Also include measuring stick 28, the groove 141 interior rear side middle part is embedded with measuring stick 28 being installed.

[0041] When different raw materials in the mixing box 11 fall into the annular disk 5, the wedge block 503 can guide the dropped raw materials. In this way, it is possible to prevent the material from falling onto the first straight bevel gear 501 and affect the rotation of the second straight bevel gear 502 .

[0042] When the operator pulls the handle 22 to make the sliding plate 27 move inside and outside, the operator can know how much raw material can be loaded in the groove 141 through the measuring scale 28 . When the slide plate 27 moves to the amount required to load and take, stop pulling the handle 22 . In this way, the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com