Powder adding device for concrete preparation

A technology for adding equipment and concrete, which is applied in the direction of clay preparation equipment, mixing operation control equipment, and sales of raw material supply equipment, etc. It can solve the problems of troublesome and inconvenient adding methods, and achieve the effect of convenient use of equipment and improvement of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

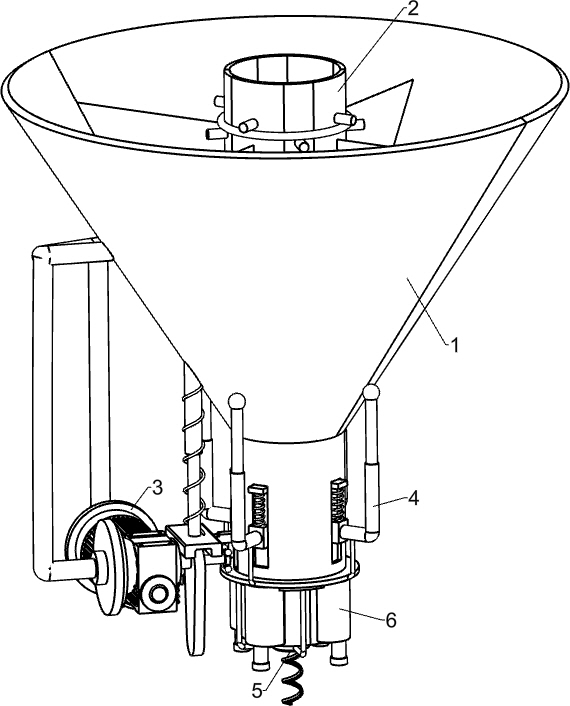

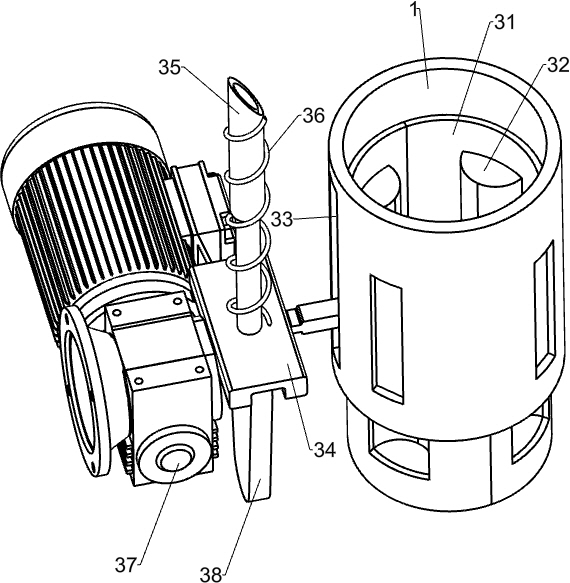

[0022] A kind of powder adding device for concrete preparation, such as Figure 1-3 As shown, it includes a storage hopper 1, a material partition assembly 2 and a discharge assembly 3. The storage hopper 1 is installed with a partition assembly 2 for storing various powder materials in an isolated manner. The discharging assembly 3 for discharging.

[0023] When it is necessary to use the device to add powder, different powders are placed in the storage hopper 1, and separated by the partition assembly 2, and then the discharge assembly 3 is controlled to start working, and the discharge assembly 3 and the partition With the cooperation of component 2, the powder material is released, and after the powder material is added, the discharge component 3 is controlled to stop working.

[0024] Partition assembly 2 includes partition 21, cylinder 22, slide plate 23, push block 24, push rod 25 and elastic rope 26, is provided with partition 21 in the storage hopper 1, and the middl...

Embodiment 2

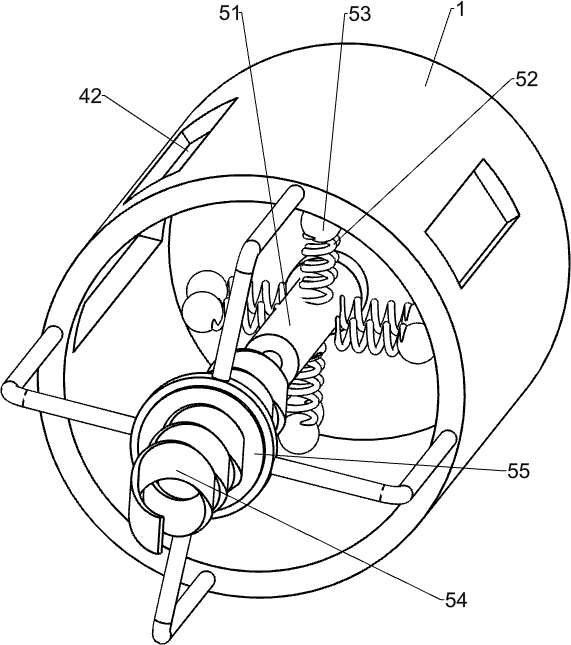

[0029] On the basis of Example 1, such as figure 1 , 4 , 5 and 6, it also includes an upper knocking assembly 4, the bottom of the storage hopper 1 is installed with an upper knocking assembly 4 that is knocked by a lifting method, and the upper knocking assembly 4 includes a bump 41, a slider 43, Knock bar 44, second spring 45 and annular plate 46, four chutes 42 are evenly spaced on the outer side of the storage hopper 1 bottom, and slide blocks 43 are all slidable in the chute 42, and the outsides of slide blocks 43 are welded with The second spring 45 is connected between the knocking rod 44, the slider 43 and the storage hopper 1, the ring plate 46 is welded between the bottom of the knocking rod 44, the right side of the cam 38 is welded with a bump 41, and the bump 41 and the ring plate 46 fits.

[0030] When the cam 38 rotates, it drives the protruding block 41 to rotate, and when the protruding block 41 rotates to contact with the annular plate 46, it drives the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com