Mortar treatment equipment

A technology for processing equipment and mortar, which is applied in pretreatment control, clay preparation device, filter and sieve, etc. It can solve problems such as uneven mixing, inability to quantitatively discharge materials, and inability to take as needed, so as to achieve high production efficiency and avoid stirring Uneven, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

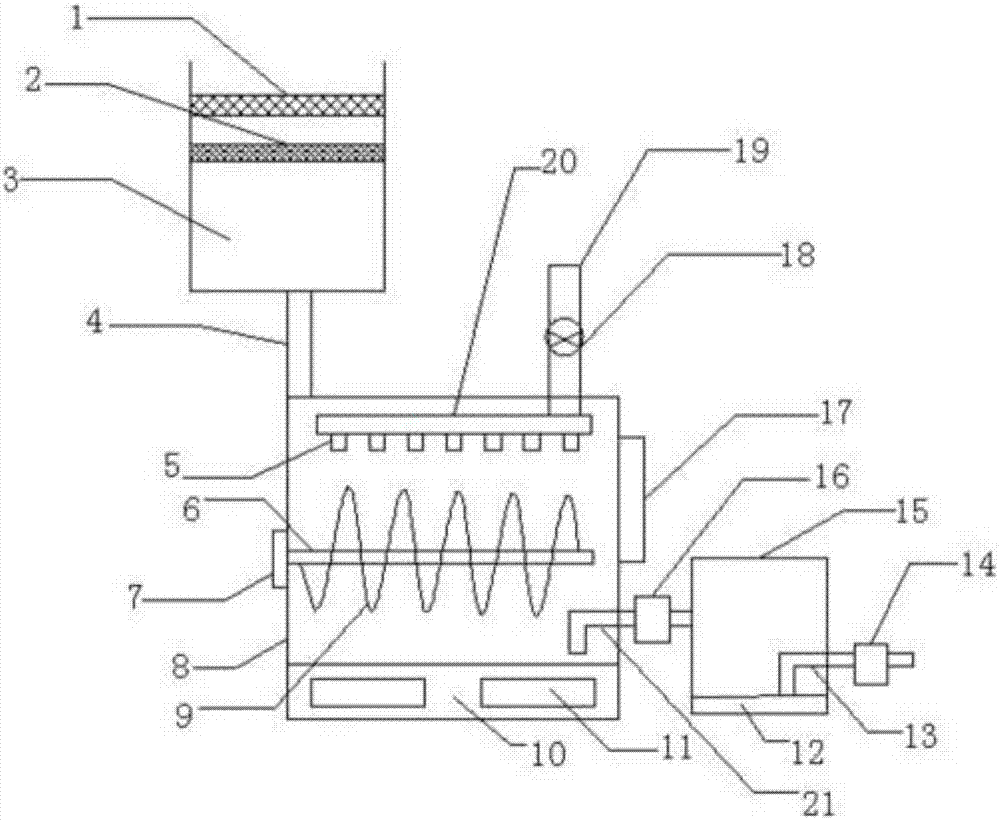

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] like figure 1 As shown, a kind of mortar processing equipment of the present invention comprises a first vibrating screen device 1, a second vibrating screen device 2, a quantitative weighing hopper 3, a mortar raw material delivery pipeline 4, a rotary water distributor 5, and a rotating shaft 6 , stirring motor 7, stirring chamber 8, stirring paddle 9, weight sensing base plate 12, mortar export pipe 13, mortar export pump 14, discharge weighing cylinder 15, connection pump 16, water volume setting panel 17, electric flow valve 18, water supply Pipeline 19, water distribution plate 20, connecting pipeline 21, the top of the mixing chamber 8 is provided with a quantitative weighing hopper 3, the quantitative weighing hopper 3 is connected with the mixing chamber 8 through the mortar raw material delivery pipeline 4, and the quantitative weighing hopper 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com