Production device for dry-mixed mortar

A production device and a technology for dry powder mortar, which are applied to unloading devices, clay preparation devices, and clay mixing devices, etc., can solve the problems of pipeline impact and wear, reduced equipment durability, and reduced production efficiency, so as to improve work efficiency and avoid problems. The effect of reduced service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

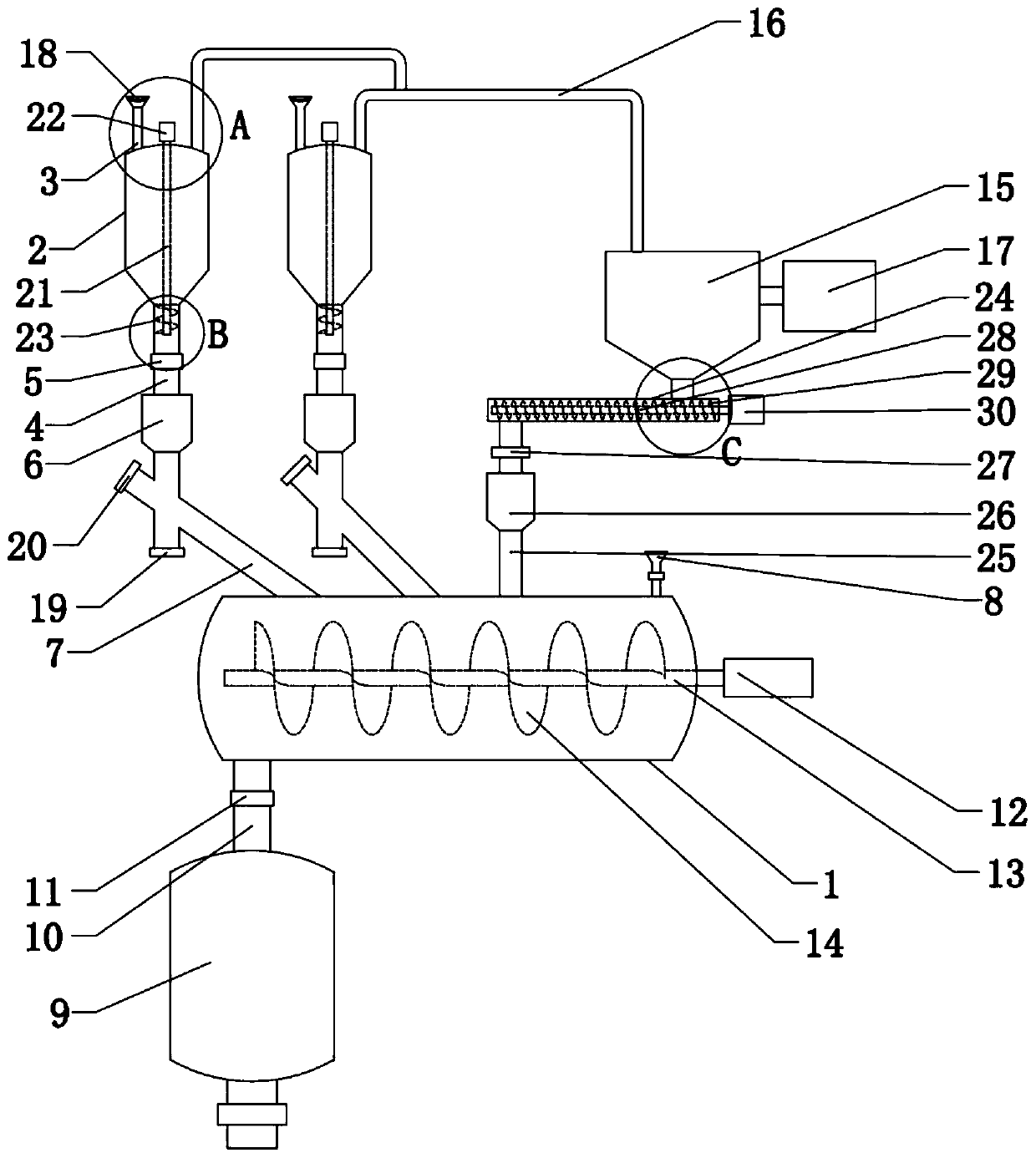

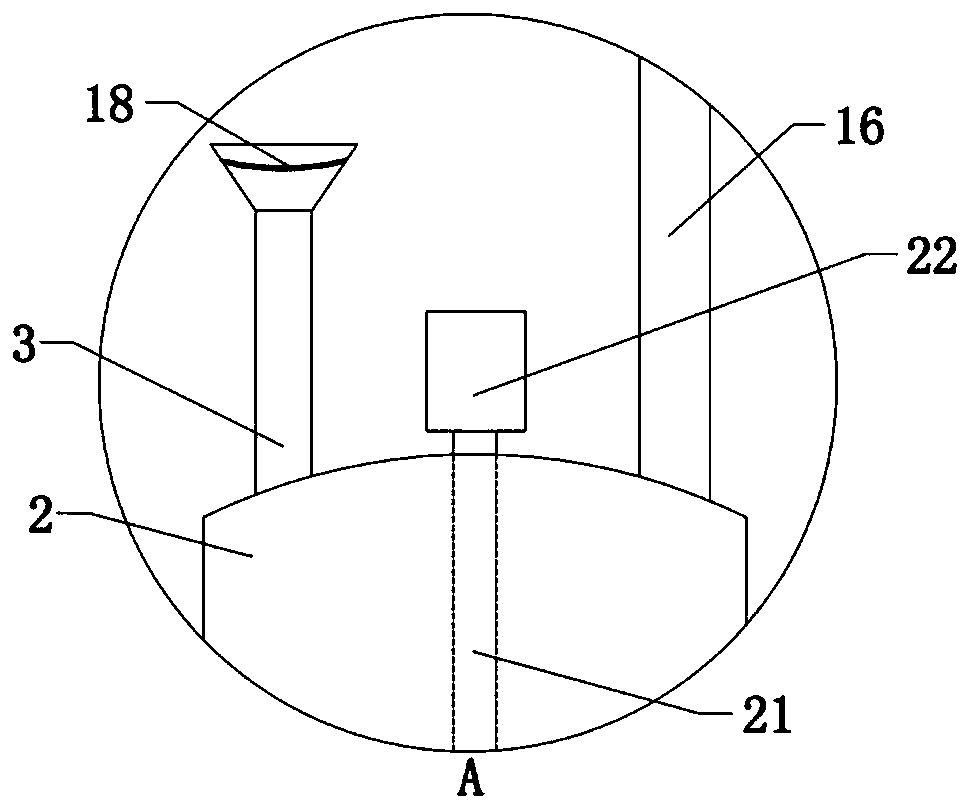

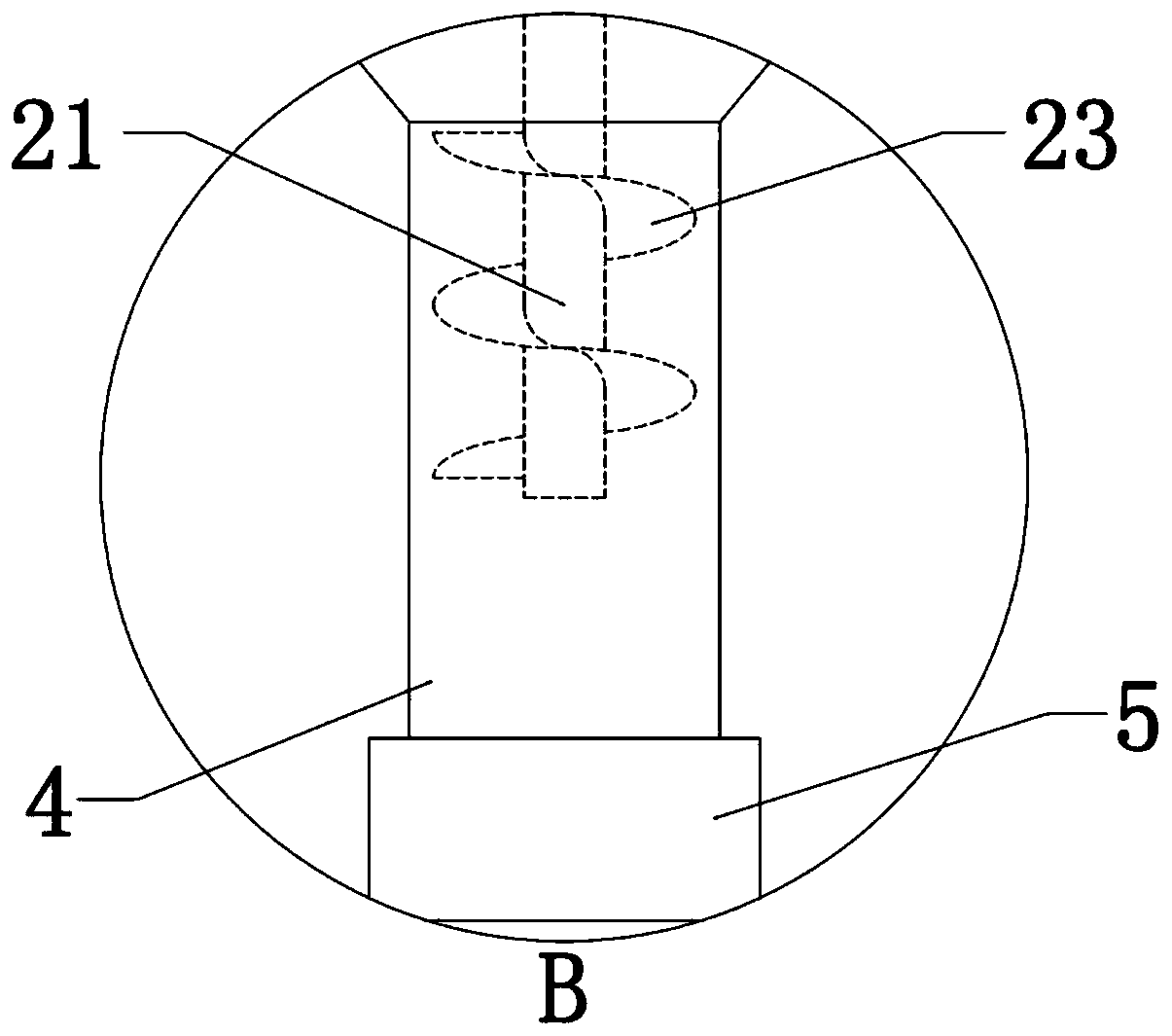

[0032] Embodiment 1: as figure 1 , 2 , 3, and 4, first, add solid raw materials to the raw material tank 2 through the feeding pipe 3, and when the solid raw materials pass through the sieve plate 18 on the feeding pipe 3, large debris cannot pass through the sieve plate 18 and stay above the sieve plate 18 After the solid raw material is added, the first pneumatic butterfly valve 5 is opened, and the raw material conveying motor 22 is turned on at the same time. The raw material conveying motor 22 drives the raw material conveying screw blade 23 to rotate by driving the raw material conveying shaft 21 to control the flow rate of the solid raw material. The raw material enters the raw material weighing tank 6 through the first raw material delivery pipe 4 to be weighed. When the preset standard is reached, the first pneumatic butterfly valve 5 is closed and the raw material delivery motor 22 is turned off at the same time, and then the bottom of the solid raw material weighing...

Embodiment 2

[0036] Embodiment 2: as Figure 5 , 6 , 7, and 8, compared to Embodiment 1, the mixing tank 1 of this embodiment adopts a closed cylindrical box-shaped structure composed of a fixed part and a movable part, and a temporary storage warehouse for finished products is arranged below the mixing tank 1 31. In the stirring state, the fixed part and the movable part form a closed cylindrical box-shaped structure. When the solid raw material enters the mixing tank 1 composed of the fixed part and the movable part, when the mixing motor 12 drives the mixing shaft 13 After the mixing screw blade 14 is rotated to stir the solid raw materials in the mixing tank 1 to form a finished mortar; After rotating, the finished mortar enters the finished product temporary storage bin 31 for temporary storage. After the finished mortar in the mixing tank 1 is discharged, the air pressure telescopic rod 32 reversely drives the movable part to move in reverse, and then switches to the stirring state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com