Improved concrete mixer

A technology of concrete mixer and mixing box, which is applied to cement mixing device, clay preparation device, mixing operation control and other directions, can solve the problems of inability to meet the needs of use, single function, simple structure, etc. well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

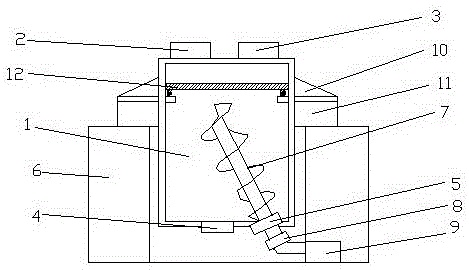

[0015] An improved concrete mixer of the present invention comprises a mixing box 1 and a bracket 6 supporting the mixing box 1, the mixing box 1 is placed in the cavity of the bracket 6, the inside of the mixing box 1 is provided with a stirring shaft 7, and the top of the mixing box 1 is provided with There are feed inlet 2 and water inlet 3, the bottom of the mixing box 1 is provided with a discharge outlet 4, one side of the discharge outlet 4 is provided with an oblique bearing plate 5, and the stirring shaft 7 is fixed on the bearing plate 5 and obliquely Stretching into the inside of the mixing box 1, the rear end of the stirring shaft 7 is provided with a rotary drive device 8, which is connected to the motor 9, and the upper and outer sides of the mixing box 1 are symmetrically provided with lugs 10, and the lugs 10 are connected to the bracket 6 are all provided with weighing device 11.

[0016] Preferably, as an example, a vibrating screen 12 is provided below the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com