Automatic proportioning system of concrete mixing station

A technology of automatic batching and batching stations, applied in batching plants, batching and batching instruments, batching weighing instruments, etc., can solve the problems of cumbersome and disordered procedures, chaotic management of batching process records, waste of batching resources, etc., to ensure product quality, Realize precise control and efficient management, and avoid cumbersome and disorderly procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

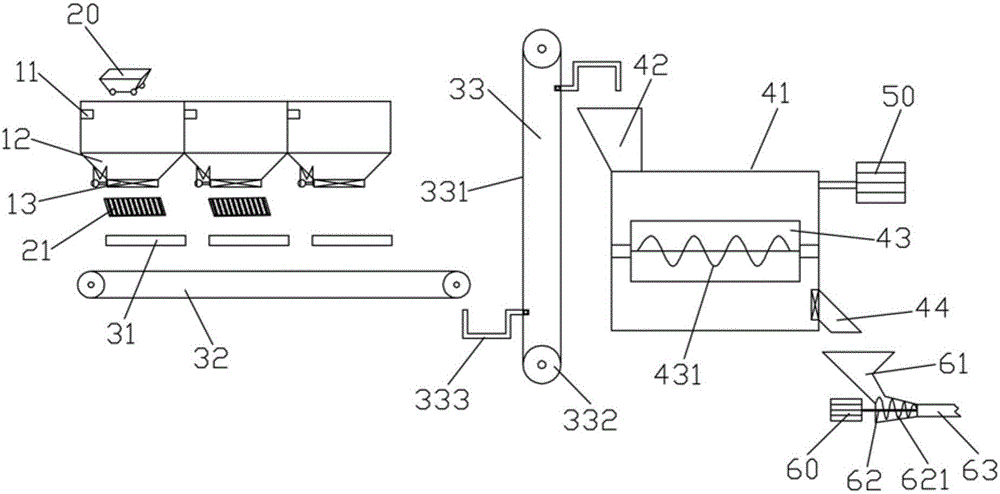

[0018] like figure 1 As shown, the automatic batching system of the concrete mixing plant includes a raw material storage system, a raw material weighing system, a mixer system, a raw material delivery system and a control system. The raw material storage system includes three silos 12 arranged side by side, and the three silos 12 are respectively Sandstone, powder and cement are stored. The upper part of the inner wall of the three silos 12 is equipped with a high-level material level gauge 11 electrically connected to the control system. The lower part of each silo 12 is equipped with an electric valve 13. The raw material delivery system Consists of a belt conveyor 32 and a bucket elevator 33, the belt conveyor 32 is located in the space directly below the three silos 12, the bucket elevator 33 is located at the tail of the belt conveyor 32, and the raw material weighing system includes three belt scales 31. The belt scale 31 is located above the belt conveyor 32 and below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com